3D Printed Tools Revolution: Transforming Your DIY Projects with Cutting-Edge Technology

Introduction to 3D Printed Tools

The Evolution of 3D Printing

The evolution of 3D printed tools, a marvel of modern technology, has been remarkable over the years. Starting as a method primarily used for prototyping, 3D printing has now carved a niche in diverse industries, especially in the creation of tools. This progression has not only made 3D printed tools more accessible to a broader audience but also significantly enhanced their capabilities, enabling enthusiasts like myself to delve into and craft with unprecedented freedom and precision.

The Impact of 3D Printed Tools

The advent of 3D printed tools has been a game-changer in many ways. It has democratized the creation and customization of tools, enabling both professionals and hobbyists to tailor solutions to their specific needs. The ability to design and print tools on-demand has revolutionized how we approach tasks, offering a new level of efficiency and personalization.

Basics of 3D Printing Tools

Embarking on the journey of 3D printing opens up a world of creativity and innovation. Understanding the foundational aspects of 3D printing is essential for anyone interested in exploring the realm of 3D printed tools. This segment delves into the fundamental concepts and essential tools required for beginners in 3D printing.

Understanding the 3D Printing Process

The Concept of Additive Manufacturing

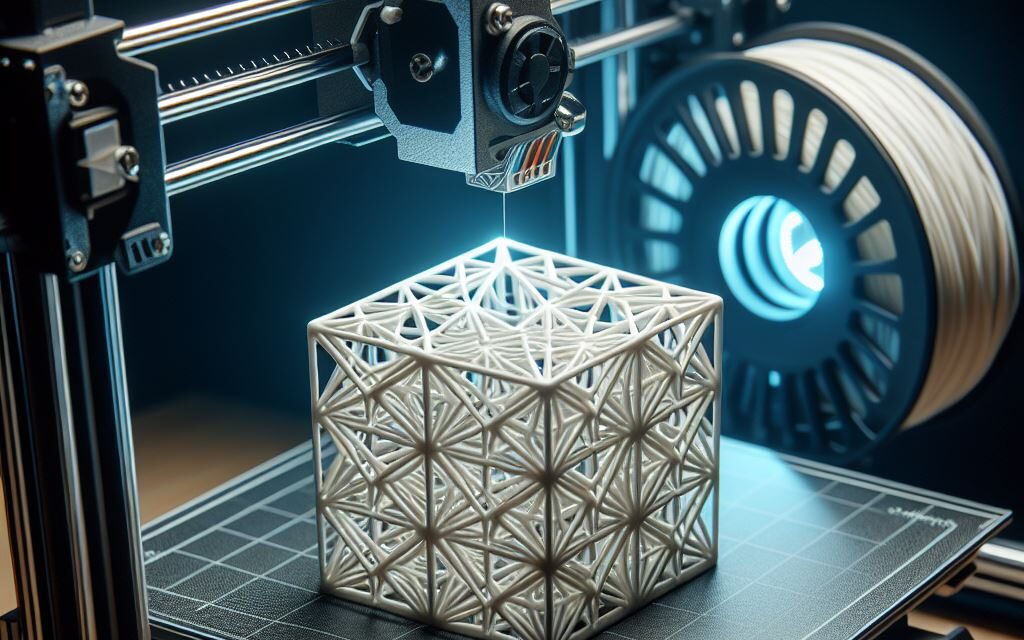

3D printing, at its essence, is about creating tangible objects from digital models. This process is known as additive manufacturing. Unlike traditional manufacturing methods that remove material to shape an object (subtractive manufacturing), 3D printing builds objects layer by layer. This method allows for the creation of complex and intricate designs that would be difficult, if not impossible, to achieve with conventional techniques.

Layer-by-Layer Fabrication

The process begins with a digital blueprint, often a 3D model created using computer-aided design (CAD) software. The 3D printer then translates this model into a physical object by depositing material, layer by layer, until the object is fully formed. This technique enables the production of parts with intricate geometries and internal structures, offering a level of design freedom that traditional methods cannot match.

Essential Tools for Beginners

Choosing the Right 3D Printer

For newcomers to 3D printing, selecting the right printer is crucial. A reliable 3D printer serves as the foundation of your printing setup. Factors such as print resolution, build volume, and material compatibility should be considered. Entry-level printers like the Ender 3 or Prusa i3 are popular choices for their balance of cost, ease of use, and performance.

The Role of Slicing Software

Slicing software plays a pivotal role in 3D printing. It acts as the translator between your 3D model and the printer. This software slices the model into thin, horizontal layers and generates the necessary code (G-code) to guide the printer. User-friendly options like Cura or Slic3r are excellent for beginners, offering intuitive interfaces and customizable settings.

Additional Tools and Accessories

- Spatula or Scraper: Essential for safely removing prints from the build plate.

- Digital Caliper: For precise measurements, ensuring your prints match your design specifications.

- Cleaning Tools: Maintenance is key. Tools like brushes, cloths, and isopropyl alcohol help keep the printer in top condition.

Advanced 3D Printing Tools and Troubleshooting

Delving deeper into the world of 3D printing unveils an array of advanced tools and techniques that can elevate your projects to new heights. This segment focuses on the specialized tools necessary for advanced 3D printing projects and highlights the importance of innovative materials in this process.

Advanced 3D Printing Tools

Specialized Tools for Advanced Projects

As you become more experienced in 3D printing, the complexity and sophistication of your projects naturally increase. This progression calls for more advanced tools that can handle the demands of intricate designs and precision.

- High-Precision 3D Scanners: These scanners are invaluable for replicating complex objects with accuracy. They capture every detail of the object, creating a precise digital model that your printer can reproduce.

- Advanced Slicing Software: Moving beyond basic slicing software, advanced programs offer a plethora of customization options, allowing more control over print settings. This includes adjusting layer height, infill density, and support structures for complex prints.

- Post-Processing Tools: Achieving a professional finish often requires post-processing. Tools like sanders, drills, and paint kits help refine the prints, enhancing their appearance and functionality.

Innovation in 3D Printing Materials

In advanced 3D printing, the choice of material is not just about what can be printed but how it contributes to the function and durability of the final product. The innovation in materials has been a driving force in expanding the capabilities of 3D printed tools.

- Specialized Filaments: The market now offers a wide range of filaments tailored for specific purposes. For example, there are filaments with added strength for tools or parts that bear weight or stress. Others are designed for flexibility, transparency, or even biocompatibility for medical applications.

- Composite Materials: These materials combine the properties of different elements to create filaments with unique characteristics. For instance, carbon fiber reinforced filaments offer high strength and stiffness, ideal for functional parts.

- Eco-Friendly Options: With sustainability in mind, there are now biodegradable and recycled filaments available, allowing eco-conscious users to continue their 3D printing endeavors without compromising on environmental values.

Advanced 3D printing tools and materials open up a world of possibilities for creators and innovators. Understanding and utilizing these tools and materials can significantly enhance the quality and functionality of your 3D printed tools. As the technology continues to evolve, staying informed and adaptable is key to making the most of these advancements.

3D Printing Troubleshooting

Navigating through the intricacies of 3D printing can sometimes be challenging, even for the most seasoned enthusiasts. Understanding common issues and their solutions is crucial in ensuring a smooth 3D printing experience. Equally important is regular maintenance of your 3D printer to prevent these issues. This part of the article focuses on troubleshooting common 3D printing problems and emphasizes the importance of ongoing maintenance.

Common 3D Printing Issues and Solutions

Even with the best setup, encountering issues in 3D printing is not uncommon. Recognizing these problems and knowing how to address them can save time and resources.

- Warping: This occurs when the print’s edges lift away from the build plate. Solutions include using a heated bed, applying adhesives like hairspray or glue, and ensuring the first layer is properly adjusted for better adhesion.

- Stringing or Oozing: Caused by extruder oozing as it moves between sections, resulting in thin strings of plastic. Tweaking the retraction settings and adjusting the printing temperature can help mitigate this issue.

- Layer Shifting: This results in misaligned layers, often due to loose belts or pulleys. Tightening the hardware and ensuring smooth movement of the printer head and bed can resolve this.

Maintaining Your 3D Printer

Routine maintenance of your 3D printer is essential for optimal performance and longevity. A well-maintained printer not only reduces the likelihood of common printing issues but also ensures consistent print quality.

- Cleaning the Print Bed: Regular cleaning is crucial for good print adhesion. Remove any residue or debris after each print and periodically clean the bed with isopropyl alcohol.

- Lubricating Moving Parts: Parts like rods and bearings need occasional lubrication to ensure smooth movement. Use suitable lubricants as recommended by your printer manufacturer.

- Updating Printer Firmware: Manufacturers often release firmware updates that improve printer performance and add new features. Keeping your firmware up-to-date ensures you’re getting the best out of your printer.

- Checking for Wear and Tear: Regularly inspect components such as belts, nozzles, and build plates for wear. Replacing worn parts promptly can prevent a multitude of printing problems.

Creative Ideas for 3D Printed Tools and Selecting the Best 3D Printers

3D printing has revolutionized the way we think about tool creation and customization. This part of the article explores a range of creative ideas for 3D printed tools tailored to everyday needs and unique challenges. It also provides insights into selecting the best 3D printers to bring these innovative ideas to life.

Creative Ideas for 3D Printed Tools

Everyday Utility Items

The potential of 3D printing in creating practical tools for everyday use is vast and varied. Here, we explore some innovative ideas that can be easily implemented using a 3D printer.

- Custom Hooks and Organizers: Personalized hooks for organizing tools, kitchen utensils, or even jewelry can be designed to fit specific spaces and needs. This includes wall-mounted hooks, under-shelf hangers, and modular organizers.

- Ergonomic Tool Grips: Custom grips for tools like screwdrivers, hammers, or garden tools can be printed to fit your hand perfectly, reducing strain and improving efficiency.

- Unique Kitchen Gadgets: From custom cookie cutters to bespoke measuring spoons, 3D printing allows you to design and create unique kitchen gadgets that are not available in stores.

- Personalized Desk Accessories: Think about custom stands for phones and tablets, ergonomic keyboard rests, or unique pen holders that add both functionality and a personal touch to workspaces.

- Home Improvement Tools: Design jigs, guides, or mounts that aid in DIY home repair and improvement tasks, tailored to specific projects or measurements.

Customized Solutions for Unique Needs

3D printing truly excels in its ability to produce customized tools for specific tasks or challenges, offering solutions that traditional manufacturing cannot.

- Specialized Repair Tools: Design and print tools that fit into narrow or awkward spaces for specific repair jobs, such as plumbing fixtures or automotive components.

- Hobbyist Accessories: Create customized parts for hobbies, like drone components, model building tools, or photography gear.

- Educational Models: 3D printing offers a way to create accurate and interactive models for educational purposes, making learning more engaging and hands-on.

- Custom Sports Equipment: Design specialized grips for racquets or bats, custom fittings for bicycles, or even personalized protective gear, all tailored to enhance performance and comfort.

- Gardening Tools: Think about custom seed planters, soil testers, or ergonomic tools designed to make gardening more accessible and enjoyable.

Best 3D Printers for Tool Projects

Choosing the Right Printer for Your Projects

The choice of 3D printer is crucial in turning your creative ideas into reality. Here’s what to consider when selecting the best 3D printer for your needs.

- Print Quality and Resolution: For detailed and precise tools, a printer with high resolution is essential. This is especially important for intricate designs or tools that require a high degree of accuracy.

- Build Volume: Consider the size of the items you plan to print. Larger build volumes allow for bigger tools or multiple prints at once, while a smaller build volume might suffice for more compact items.

- Material Compatibility: Depending on your projects, you might need a printer that can handle various materials, from standard PLA to more specialized filaments like flexible TPU or durable PETG.

- Ease of Use and Reliability: Especially for beginners, a user-friendly interface and reliable performance are key factors. Look for printers with good support and community backing for troubleshooting and advice.

Top Picks for Various Needs

- For Beginners: Printers like the Ender 3 series offer a good balance of affordability, ease of use, and print quality.

- For Advanced Users: Printers like the Prusa i3 MK3S or the Ultimaker S3 provide higher precision, more material options, and advanced features for complex projects.

- For Professional Use: High-end printers like the Formlabs Form 3 offer exceptional detail and material versatility, suitable for professional-grade tool creation.

Why Choose These Printers?

When it comes to 3D printing, especially for tool-making, the choice of the printer can make a significant difference in the outcome of your projects. This part of the article will delve deeper into the key features to consider when selecting a 3D printer and how to analyze the balance between price and performance. Understanding these aspects will guide you in making an informed decision that aligns with your 3D printing needs and goals.

Features to Consider

Selecting the right 3D printer involves considering several crucial features that impact its functionality and suitability for your specific tool-making projects.

- Build Volume: The build volume determines the size of the objects you can print. If your projects involve larger tools or parts, a printer with a larger build volume is necessary. Conversely, for smaller, intricate tools, a smaller build volume may suffice.

- Material Compatibility: Different projects may require different materials, from standard PLA and ABS to more specialized materials like TPU or PETG. Ensure the printer supports the materials needed for your tool-making projects.

- Layer Resolution: Higher resolution printers can produce finer details and smoother surfaces, crucial for tools that require precision. Lower resolution printers might be adequate for more robust, less detailed tools.

- Ease of Use: User-friendly interfaces, straightforward software, and reliable customer support are important, especially for beginners. Features like automatic bed leveling and filament sensors can also enhance the printing experience.

- Connectivity and Software: Consider the printer’s compatibility with various slicing software and its connectivity options, such as USB, Wi-Fi, or SD card slots, for ease of transferring your designs to the printer.

Price vs. Performance Analysis

Balancing the cost and the capabilities of a 3D printer is key to making a worthwhile investment.

- Budget Considerations: Entry-level printers are more affordable and can be a great starting point. They often provide a good balance between essential features and cost, making them ideal for beginners or those with limited budgets.

- Investing in Quality: Mid-range to high-end printers usually offer higher build quality, better resolution, and more advanced features. They are a worthwhile investment for those planning to undertake complex or frequent tool-making projects.

- Long-Term Value: Consider the long-term value of the printer. A more expensive printer with durable construction and the ability to handle a wide range of materials might offer better value over time compared to a cheaper model that requires frequent repairs or upgrades.

Choosing the right 3D printer for tool-making is a decision that requires careful consideration of various features and an analysis of price versus performance. By understanding your specific needs, the complexity of your projects, and your budget constraints, you can select a printer that not only meets your current requirements but also serves you well in the long term. Whether you opt for an entry-level model or a professional-grade machine, the key is to find the right balance that aligns with your tool-making aspirations and the evolving landscape of 3D printing technology.

Helpful Suggestions for 3D Printing Projects, Conclusion, and FAQs

Embarking on a 3D printing project, particularly in tool-making, can be an exciting journey filled with learning and creativity. This part of the article offers practical suggestions to enhance your 3D printing experience, from designing your own tools to leveraging the 3D printing community for support and inspiration.

Helpful Suggestions for 3D Printing Projects

Designing Your Own Tools

Starting with Simple Designs

The process of creating your own tools with 3D printing begins with a simple yet critical step – designing. Here’s how to navigate this phase:

- Begin with Basic Shapes: Start by designing simple tools or parts. This might include basic shapes like hooks, handles, or brackets. These simple projects allow you to understand the basics of 3D design and printing.

- Use User-Friendly Software: For beginners, software like Tinkercad offers an intuitive platform to start designing without a steep learning curve. As you gain more confidence, you can graduate to more sophisticated software like Fusion 360 or SolidWorks.

- Understand Design Constraints: Learn about the limitations and capabilities of your 3D printer. This includes understanding the maximum build size, the resolution, and the materials you can print with.

Progressing to Complex Designs

- Incremental Learning: Once comfortable with basic designs, gradually introduce more complexity into your projects. This could involve integrating moving parts, intricate details, or using a combination of materials.

- Experiment and Iterate: Don’t hesitate to experiment. 3D printing is largely about trial and error. Each iteration teaches you something new and brings you closer to perfecting your design.

Collaborating with the 3D Printing Community

The 3D printing community is an invaluable resource for anyone, from beginners to advanced users.

- Join Online Forums and Groups: Platforms like Reddit, Thingiverse, and dedicated 3D printing forums are great places to start. These communities are full of experienced individuals who offer advice, share their designs, and provide solutions to common problems.

- Attend Workshops and Meetups: Local workshops or meetups can be incredibly beneficial. They provide hands-on experience and the opportunity to learn from others’ experiences.

- Participate in Collaborative Projects: Engaging in group projects or challenges can enhance your skills. Collaboration merges diverse skills and perspectives, leading to innovative solutions and learning opportunities.

Final Thoughts and Future Trends

The Future of 3D Printing in Tool Making

The future of 3D printing in tool making is incredibly promising. With advancements in printing technologies and materials, the potential for creating more complex, durable, and functional tools is expanding. We are likely to see more integration of smart technology and even greater customization.

How to Stay Updated with 3D Printing Innovations

To stay ahead in this rapidly evolving field, keep an eye on tech news, follow leading 3D printing blogs, and participate in community discussions. Continuous learning and adaptability are key to making the most of 3D printing technologies.

Conclusion

3D printing tools is a journey filled with endless possibilities. Whether you are a beginner or an advanced user, the world of 3D printing offers a unique opportunity to create tools that are tailored to your specific needs. The blend of creativity, technology, and practical application makes this a fascinating and rewarding endeavor.

FAQs

- What are the best materials for 3D printing tools?

PLA is great for beginners due to its ease of use, while materials like ABS, PETG, and TPU are ideal for more durable and specialized tools. - Can I 3D print tools that are as strong as traditionally manufactured ones?

While 3D printed tools can be quite strong, especially when using specific filaments, they may not always match the strength of traditionally manufactured tools in all applications. - How can I improve the finish of my 3D printed tools?

Post-processing techniques like sanding, painting, or using coatings can significantly improve the finish and durability of 3D printed tools. - Is it cost-effective to 3D print my own tools?

It can be, especially for customized or unique tools. For more standard tools, it depends on the material costs and the value you place on customization. - How do I ensure my 3D printed tools are safe to use?

Always test your tools under safe conditions, ensure they are printed with the appropriate material for the task, and regularly inspect them for wear and tear.

Resources

- https://www.autodesk.com/products/fusion-360/personal

- https://www.tinkercad.com/

- https://slic3r.org/

- https://ultimaker.com/software/ultimaker-cura/

- https://www.thingiverse.com/

- https://www.solidworks.com/