3D Print Stringing: How to Solve The Problem

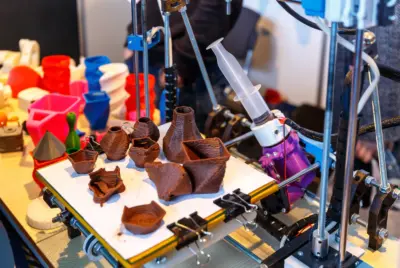

Introduction to 3D Print Stringing

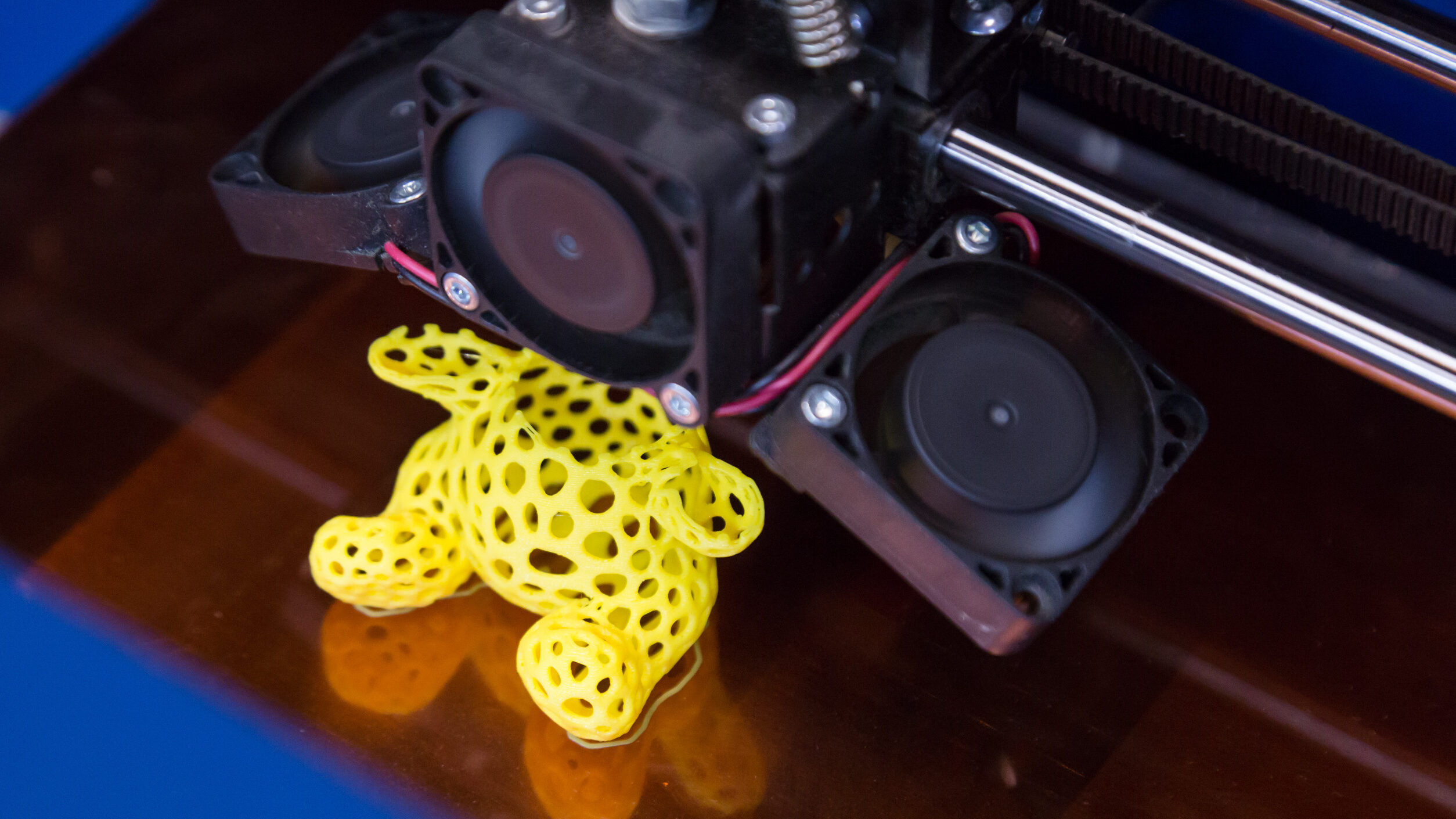

Hi there, fellow 3D printing enthusiasts! Today, I’m diving into a topic that often baffles many of us in the 3D printing community: stringing. What is 3D print stringing, you ask? It’s those pesky little strings of plastic that sometimes appear between the parts of your print, marring its perfection. And why should you care? Well, it’s simple: if you’re as passionate about flawless prints as I am, understanding and preventing stringing is key to achieving those immaculate results.

Detailed Explanation of Stringing Mechanism

Understanding the Physics of Filament Behavior

Filament behavior in 3D printing is a critical aspect that combines the principles of materials science and thermodynamics. When we dive into the mechanics of how a filament behaves during the printing process, several key factors come into play:

- Heating and Malleability: In the extruder, the filament is heated to a specific temperature that makes it malleable. This malleability is crucial for the filament to be precisely deposited in the desired pattern by the printer.

- Cooling and Solidification: Post extrusion, the filament begins to cool and solidify. This cooling process is what gives the print its final structure. The rate of cooling is critical; too fast can lead to brittleness, while too slow may result in deformation or stringing.

- Viscosity and Movement: The viscosity, or thickness, of the molten filament is a significant factor. Viscosity affects how the filament flows out of the nozzle and how it behaves mid-air before solidifying. Additionally, the movement of the printer head during printing can influence the occurrence of stringing. If the filament doesn’t break cleanly after being extruded and the printer head moves to a new location, it can leave behind those fine strings that we want to avoid.

Heat Dynamics in 3D Printing

Temperature Control: The key to successful 3D printing lies in managing the temperature correctly. Let’s break this down:

- Overheating Issues: When the filament is overheated, it becomes too fluid. This increased fluidity can cause the filament to droop or string between parts of the print, especially when the printer head moves.

- Underheating Problems: On the other hand, if the filament is not heated enough, it won’t flow smoothly through the nozzle, leading to uneven extrusion and potential defects in the print.

- Optimal Temperature: Finding the ideal printing temperature for each type of filament is essential. This optimal temperature is a balance — high enough to allow a smooth flow but not so high that it causes the filament to become overly fluid and stringy.

Extrusion and Cooling Processes

The Extrusion Process: This involves more than just pushing the filament through a heated nozzle. It’s about precision and consistency:

- Speed and Consistency: The rate at which the filament is extruded and the consistency of this extrusion are vital for print quality. Uneven extrusion can lead to various issues, including blobs and stringing.

- Cooling Mechanisms: Following extrusion, cooling plays a pivotal role.

- Rapid Cooling Benefits: Quick cooling helps in solidifying the filament faster, which can be crucial in reducing stringing. When the filament solidifies quickly, it minimizes the chance of it stretching into strings as the print head moves to another area of the print.

- Cooling Techniques: This can involve the use of cooling fans or optimizing the print environment to facilitate faster cooling without introducing other issues like warping.

The Causes of Stringing in 3D Printing

Grasping the reasons behind 3D print stringing is crucial for both troubleshooting and preventing this frequent challenge in 3D printing. Influenced by a range of factors, from the type of materials to environmental conditions, let’s dive into what contributes to 3D print stringing:

Material Factors

The type of filament you use significantly impacts the likelihood of stringing. Here’s how:

- Different Filament Properties: Filaments like PLA, ABS, and PETG each have unique properties. Some, like ABS, are more prone to stringing due to their composition and the higher temperatures required for printing.

- Quality of Filament: The quality of the filament also matters. Lower quality filaments may have impurities or inconsistent diameters, which can lead to irregular extrusion and stringing.

- Moisture Absorption: Some materials are hygroscopic, meaning they absorb moisture from the air. This moisture can cause issues during printing, including stringing, as it turns to steam and disrupts the extrusion process.

Printer Settings

Printer settings play a crucial role in the occurrence of stringing. These settings need to be optimized based on the material and the specific model of the printer:

- Temperature Settings: The extruder temperature needs to be high enough to melt the filament but not so high that it becomes overly runny, leading to strings.

- Print Speed: The speed at which the printer operates can affect stringing. Faster speeds might cause the filament to stretch and string, especially between distant points.

- Retraction Settings: Retraction is when the printer pulls back the filament during non-print moves to prevent dripping. Incorrect retraction settings can be a primary cause of stringing. This includes both the distance of retraction and the speed at which it occurs.

Environmental Influences

The environment in which you print can also affect the occurrence of stringing:

- Humidity: High humidity can cause filament materials to absorb moisture, leading to stringing. This is especially true for filaments like PLA and Nylon.

- Temperature Fluctuations: Fluctuations in the room temperature can affect the cooling rate of the filament, potentially causing stringing.

- Airflow: Direct airflow, such as from an AC vent or a fan, can unevenly cool the print, leading to stringing. Conversely, a lack of adequate airflow can lead to poor cooling and, subsequently, stringing.

Comparison of Different Filament Types

PLA vs. ABS vs. PETG: Stringing Tendencies

In 3D printing, the filament choice greatly affects the final result, particularly with respect to 3D print stringing tendencies. Let’s examine how various filament types stack up in this context:

PLA vs. ABS vs. PETG: Stringing Tendencies

- PLA (Polylactic Acid): PLA is popular for its ease of use and is less prone to stringing, mainly due to its lower printing temperature requirements. It cools and solidifies quickly, which helps in reducing the occurrence of strings.

- ABS (Acrylonitrile Butadiene Styrene): ABS, known for its strength and durability, generally requires higher temperatures to print effectively. This higher temperature can make ABS more susceptible to stringing, as the filament remains in a more fluid state for longer.

- PETG (Polyethylene Terephthalate Glycol): PETG offers a middle ground, combining some of the ease of printing seen with PLA and the strength and temperature resistance of ABS. It tends to have fewer stringing issues than ABS but may require more fine-tuning compared to PLA.

Handling Tips for Various Filaments

Each filament type demands specific handling techniques to minimize stringing:

- For PLA:

- Use moderate retraction settings. Over-retraction can cause issues, but too little can lead to stringing.

- Cooler print temperatures are usually more effective, as PLA doesn’t require high heat to print well.

- Ensure proper cooling during printing, as PLA solidifies quickly.

- For ABS:

- Fine-tuning the temperature is crucial. Too hot, and you get stringing; too cold, and the filament won’t bond properly.

- An enclosed print environment can help maintain a consistent temperature, reducing warping and stringing.

- ABS might require a higher retraction speed to deal with its fluidity at printing temperatures.

- For PETG:

- PETG is somewhat sticky, so careful retraction settings are vital to prevent stringing while ensuring good layer adhesion.

- It usually prints well at a temperature range that is higher than PLA but lower than ABS.

- Balancing cooling and heating is key, as PETG benefits from both for optimal printing.

Selecting the Right Filament for Your Project

Choosing the appropriate filament hinges on the specific requirements of your project:

- PLA: Ideal for projects that require fine details and minimal post-processing. It’s also great for beginners due to its ease of use.

- ABS: Suited for parts that need to be durable and withstand higher temperatures. It’s often used for functional parts or components that might be exposed to stress.

- PETG: A versatile choice that offers both strength and ease of printing. It’s a good option for a variety of projects, particularly when you need a balance between detail and durability.

Proactive Steps to Prevent Stringing

Preventing stringing in 3D printing involves a combination of choosing the right materials, tweaking printer settings, and ensuring an optimal printing environment. Let’s explore these aspects in detail:

Choosing the Right Material

The first step in preventing stringing is to select the appropriate filament based on your project’s needs and the filament’s propensity for stringing:

- Filament Selection: Understand the characteristics of different filaments. PLA, for instance, is generally less prone to stringing compared to ABS or TPU. If you’re facing stringing issues, consider switching to a filament that’s less likely to string.

- Quality of Filament: High-quality filaments with consistent diameter and composition tend to string less. It’s worth investing in good quality filament to avoid stringing and other printing issues.

Optimal Printer Settings

Fine-tuning your printer settings can significantly reduce the chances of stringing:

- Temperature Adjustments:

- Melting Point: Each filament type has an optimal temperature range where it melts effectively but doesn’t become too runny. Experiment within the recommended temperature range for your filament to find the sweet spot.

- Gradual Adjustments: Small incremental adjustments can make a significant difference. Monitor the effects of each change on stringing.

- Retraction Settings:

- Retraction Distance: This refers to how far the filament is pulled back when the nozzle moves between print sections. If too little, it can lead to stringing; if too much, it might cause clogs or under-extrusion.

- Retraction Speed: Faster retraction can help prevent oozing, but too fast may grind the filament or cause it to snap. Finding a balanced speed is key.

Creating an Ideal Printing Environment

The environment where you print plays a critical role in the quality of your prints:

- Temperature Stability: Keep the printing area free from drafts and sudden temperature changes. An enclosed printer can help maintain a consistent temperature, especially important for materials like ABS.

- Humidity Control: High humidity can affect filament properties, especially for hygroscopic materials like Nylon. Using a dehumidifier or storing filaments in a dry, controlled environment can help.

- Clean and Organized Space: Regularly clean your printer and the surrounding area to ensure no dust or debris interferes with the printing process.

Troubleshooting Existing Stringing Issues

3D print stringing can be a challenging issue in 3D printing, but there are effective methods to tackle it during and post the printing process. Let’s explore how to identify and resolve 3D print stringing problems:

Post-Printing Fixes

If you notice stringing after your print is complete, here are some post-processing techniques to clean it up:

- Manual Removal: Use fine tweezers or a sharp blade to carefully remove the strings. This method is effective for minor stringing and requires a steady hand.

- Heat Treatment: Applying gentle heat (like from a heat gun or hairdryer) can soften and remove fine strings. Be cautious not to melt or deform the rest of the print.

- Chemical Smoothing: For certain materials like ABS, chemical solvents (e.g., acetone vapor) can be used to smooth out the surface and eliminate strings. This should be done in a well-ventilated area with proper safety precautions.

Adjusting Printer Settings Mid-Print

Altering settings during a print is risky but can be necessary to salvage a print:

- Temperature Adjustments: If you notice stringing, slightly lowering the printing temperature can help. Make small adjustments to avoid drastic changes that could affect print quality.

- Speed and Retraction: Increasing retraction speed or distance can also be effective. Monitor the print closely after making these changes.

Step-by-Step Guide to Diagnosing Stringing

When facing stringing issues, a systematic approach can help identify and solve the problem:

- Check Filament Quality: Ensure the filament is dry and undamaged. Moist or poor-quality filament can increase the likelihood of stringing.

- Examine Printer Settings: Review your temperature, print speed, and retraction settings. Compare them with recommended settings for your filament type.

- Assess Environmental Conditions: Check for drafts, temperature fluctuations, or high humidity in your printing environment.

- Hardware Checks: Inspect the nozzle and extruder for any signs of clogging or wear. Ensure that the printer is properly calibrated and leveled.

Common Stringing Scenarios and Solutions

Different printing scenarios can lead to stringing. Here’s how to address some common ones:

- High-Temperature Materials: If stringing occurs with materials like ABS or PETG, try reducing the printing temperature and increasing the cooling.

- Intricate Models with Many Jumps: Increase retraction distance and speed to prevent oozing as the print head moves between sections.

- Fast Printing Speeds: Slowing down the print speed can reduce stringing, as it allows more time for the filament to cool and solidify.

When to Seek Professional Help

In some cases, stringing can be a sign of deeper issues:

- Persistent Problems: If stringing continues despite trying various fixes, it might be due to hardware issues like a worn-out nozzle or extruder problems.

- Complex Technical Issues: If you suspect the problem is beyond basic troubleshooting, like firmware issues or mechanical faults, it’s time to consult a professional.

- Printer Manufacturer Support: Reaching out to the printer manufacturer can provide insights into specific issues related to your printer model.

Safety Considerations

In 3D printing, safety is crucial, particularly when managing high temperatures and hazardous materials related to 3D print stringing. Here are key safety considerations to be aware of:

Handling High Temperatures Safely

The hot end of a 3D printer can reach very high temperatures, necessary to melt various types of filaments. This presents a risk of burns and other injuries. To handle these high temperatures safely:

- Use Protective Gear: Heat-resistant gloves can protect your hands when you need to be near the hot end or remove completed prints. Face shields can also be useful, especially when dealing with potential splatters from certain materials.

- Be Aware of the Hot End: Always be conscious of where the hot end is during operation. Avoid touching it directly during or immediately after printing.

- Proper Handling Techniques: Learn and practice safe methods for handling parts of the printer that may become hot, such as using tools to remove finished prints instead of direct contact.

Dealing with Hazardous Materials

Certain filaments in 3D printing may emit harmful fumes, particularly in poorly ventilated spaces, posing a risk when dealing with 3D print stringing. To minimize these hazards:

- Adequate Ventilation: Ensure that your printing area is well-ventilated. If possible, use exhaust fans or print in a space with active air circulation.

- Use of Filters: Consider using printers equipped with filters or installing aftermarket filters to help reduce the release of fumes into your environment.

- Choosing Safer Filaments: For indoor printing, opt for filaments known to emit fewer harmful fumes, like PLA, as opposed to ABS, which can release more toxic vapors.

General 3D Printing Safety Tips

General safety practices are crucial to prevent accidents and ensure a safe printing environment:

- Clutter-Free Area: Keep the printing area free of unnecessary items and clutter. This reduces the risk of accidentally knocking something into the printer or having items catch fire.

- Secure Clothing and Hair: Loose clothing and hair can get caught in the moving parts of the printer. Secure these to prevent entanglement, which can lead to injuries or damage to the printer.

- Stable Printing Surface: Ensure that your printer is placed on a stable and level surface. This reduces the risk of the printer tipping over or vibrating excessively, which can cause print failures or damage.

- Electrical Safety: Be mindful of the printer’s electrical connections. Avoid overloading power sockets and ensure cables are neatly organized and not frayed.

Advanced Tips for Managing Stringing

For those immersed in 3D printing and seeking to perfect their craft, advanced strategies are key to enhancing print quality and effectively reducing 3D print stringing issues:

Expert Material Choices

Exploring a broader range of filaments can provide solutions to stringing issues:

- Specialized Filaments: Some advanced or specialized filaments are engineered to reduce stringing. These might include composites or filaments with additives that improve print quality.

- Understanding Material Properties: Each filament type, from standard PLA to more exotic materials, has unique properties. Understanding these can guide you in selecting the right material for your print job to minimize stringing.

- Testing and Experimentation: Sometimes, the solution lies in experimenting with different materials to see which one best suits your specific printing needs and setup.

Fine-Tuning Printer Settings

Going beyond basic settings can yield significant improvements:

- Advanced Retraction Settings: Experiment with retraction settings beyond the standard recommendations. This includes tweaking the retraction speed and distance for your specific printer (Formlabs) and filament type.

- Layer Height and Print Speed: Adjusting the layer height and print speed can also impact stringing. Thinner layers and moderate speeds can often produce cleaner prints with less stringing.

- Temperature Gradients: Experiment with different temperature settings throughout the print. For example, starting with a higher temperature for the first few layers and then reducing it can help with adhesion and reduce stringing.

Utilizing Software Tools

Software tools can offer advanced features to combat stringing:

- Slicing Software Features: Modern slicing software provides advanced features like coasting, wiping, and variable layer heights that can help reduce stringing.

- Custom Profiles: Creating and refining custom profiles for your specific printer and filament types can lead to significant improvements in print quality.

Maintenance Tips for Printers

Regular maintenance is key to consistent, high-quality 3D printing results:

Routine Printer Maintenance for Optimal Performance

- Regular Cleaning: Keeping the extruder and gears clean ensures smooth filament flow. Accumulated debris can cause extrusion problems leading to stringing.

- Checking Mechanical Parts: Regularly inspect belts, pulleys, and other mechanical components for wear and tear. Loose or worn parts can affect print accuracy.

Calibration Techniques to Reduce Stringing

Proper calibration is essential for minimizing stringing:

- Bed Leveling: A level print bed ensures even layer application, which is crucial for reducing stringing.

- Extruder Calibration: Ensure that your extruder is properly calibrated. This affects how much filament is extruded and can play a significant role in preventing stringing.

- Axis Alignment: Make sure that all axes of your printer are properly aligned. Misalignment can cause uneven movements and lead to stringing issues.

Importance of Cleanliness and Component Care

A clean and well-maintained printer is less likely to encounter stringing issues:

- Nozzle Care: Regularly cleaning the nozzle can prevent clogs, which can cause stringing and other printing issues.

- Component Replacement: Be proactive in replacing worn components. For instance, a worn nozzle can change the characteristics of the extruded filament, leading to stringing.

Impact of Slicing Software and Settings

Slicing software, crucial for converting your 3D models into printable layers, significantly impacts print quality, especially in addressing 3D print stringing. Here’s a guide on optimizing your slicing software and settings for the best outcomes in combating 3D print stringing:

Choosing and Configuring Slicing Software

Different slicing programs offer unique features and settings that can significantly influence print quality:

- Software Selection: Popular slicers like Cura, Slic3r, and PrusaSlicer each have their strengths. For instance, Cura is known for its user-friendly interface, while Slic3r offers advanced customization options.

- Feature Utilization: Take advantage of the specific features offered by your chosen slicer. This might include options for support structures, layer height adjustments, and more, which can all impact stringing.

- Software Familiarity: Spend time getting to know your software. Understanding its capabilities and how to navigate its settings is crucial for fine-tuning your prints.

Optimizing Slicer Settings to Minimize Stringing

Adjusting slicer settings is key to reducing stringing:

- Retraction Settings: The retraction distance and speed are vital. They control how the filament is pulled back when the nozzle moves between print sections, preventing oozing and stringing.

- Temperature Settings: Each filament has an optimal printing temperature. Finding this sweet spot can reduce stringing.

- Travel Speed: Adjusting the speed at which the print head moves between sections can also impact stringing. Faster travel speeds can reduce the time the filament has to ooze.

The Role of Software Updates and Community Presets

Staying updated with software and utilizing community knowledge can enhance print quality:

- Regular Updates: Keep your slicing software updated to take advantage of the latest features and improvements.

- Community Presets: Many slicers have presets shared by the community, which can be a great resource, especially for specific printer models or unusual filament types.

How to avoid Stringing – 3D Print Beginner Tutorial

Community and Expert Insights

Tips from Experienced 3D Printing Enthusiasts

Gathering tips and tricks from those who have spent hours tinkering with their 3D printers is invaluable. Experienced enthusiasts often share unique, practical solutions that aren’t found in manuals. For instance, they might recommend specific filament brands known for minimal stringing or share custom settings that have worked for them.

Expert Advice on Dealing with Stringing

Professional 3D printers and engineers bring a technical perspective to managing 3D print stringing, delving into advanced material properties, the effects of printer hardware modifications, and cutting-edge research in 3D printing technologies aimed at minimizing stringing issues.

Leveraging Community Forums and Resources

Online forums, social media groups, and specialized 3D printing websites offer a wealth of insights on 3D print stringing. Interacting with these communities brings real-time feedback, a variety of solutions, and support from fellow enthusiasts. Additionally, platforms like Thingiverse provide downloadable settings and models specifically designed to tackle 3D print stringing challenges.

The Future of Stringing Prevention in 3D Printing

Looking ahead, the fight against stringing in 3D printing is evolving with technology and material science:

Emerging Technologies

- Advanced Printers: New printer models with improved hardware precision and better temperature control are on the horizon, which could significantly reduce stringing issues.

- Software Innovations: Future slicing software might incorporate AI and machine learning to automatically adjust settings for optimal print quality, including stringing reduction.

Innovations in Materials

- New Filament Formulations: Researchers and manufacturers are constantly developing new filament materials that are less prone to stringing, more durable, and easier to print.

- Smart Materials: The development of ‘smart’ materials that can adapt their properties during the printing process could revolutionize how we address common printing issues like stringing.

Conclusion

We’ve delved deeply into the world of 3D print stringing, exploring everything from its basic understanding to proactive strategies and effective troubleshooting techniques. Armed with this comprehensive knowledge, you’re well-equipped to tackle this frequent printing challenge. Remember, the key to mastering 3D print stringing lies in continuous experimentation and persistence. Keep refining your approach, and soon you’ll achieve the ideal balance for flawless prints.

FAQs

- What’s the best filament to use to avoid stringing?

PLA (Polylactic Acid) is generally considered the best filament to avoid stringing due to its lower printing temperature and quick cooling properties. PLA is less prone to oozing and stringing compared to other filaments like ABS or PETG. However, it’s important to note that the choice of filament also depends on the specific requirements of your project. - How important are retraction settings in preventing stringing?

Retraction settings are crucial in preventing stringing. They control how much the filament is pulled back into the nozzle when the print head moves between different sections of the print. Proper retraction prevents the filament from oozing out of the nozzle during these movements. Adjusting the retraction distance and speed can significantly reduce stringing. - Can environmental factors really affect my prints that much?

Yes, environmental factors can significantly affect print quality. Factors such as ambient temperature, humidity, and airflow can all impact how the filament behaves during printing. High humidity, for example, can make filaments like PLA absorb moisture, leading to stringing and other issues. Similarly, drafts or uneven cooling can cause the filament to cool inconsistently, also leading to stringing. - Are there any software tools specifically for managing stringing?

While there are no software tools designed exclusively for managing stringing, most slicing software like Cura, Slic3r, and PrusaSlicer offer settings that can help minimize it. These include adjustments for temperature, retraction settings, print speed, and travel speed. Some slicers also offer advanced features like coasting, wiping, and varying layer heights that can further reduce the chances of stringing. - How do I fix stringing if it occurs mid-print?

If stringing occurs mid-print, you can try to adjust the settings on your printer if it allows for mid-print adjustments. Lower the printing temperature slightly to see if it reduces stringing, and increase the retraction distance or speed. However, be cautious with making these adjustments mid-print, as drastic changes can affect the print’s overall quality. It’s often safer and more effective to let the print finish, analyze what might have caused the stringing, and then make the necessary adjustments for the next print.

Resources

https://www.3dnatives.com/en/3d-software-beginners100420174/

https://www.chitusystems.com/