Flexible 3D Printer Filament: Ultimate Guide

1. Introduction

What is Flexible 3D Printer Filament?

Flexible 3D printer filament, often highlighted in discussions about advanced 3D printing materials, stands out for its significant pliability, which differentiates it from more traditional filaments such as PLA (Polylactic Acid) or ABS (Acrylonitrile Butadiene Styrene). This unique type of filament is crafted from elastomeric polymers, which grant the prints an ability to bend, stretch, and compress without losing form. The inherent flexibility of these materials introduces a vast range of practical applications that are transforming various industries.

Key Characteristics of Flexible 3D Printer Filament:

- Elasticity: Allows the material to stretch significantly before breaking.

- Softness: Depending on the specific type, the filament can feel rubbery and soft, which is ideal for specific uses.

- Durability: Despite their softness, these filaments are incredibly durable and can withstand physical stresses that would break or deform harder materials.

Importance of Flexibility in 3D Printing

The attribute of flexibility is not merely a novel feature; it serves critical functions across several domains. For instance, in wearable technology, the ability of a material to conform comfortably to the human body is paramount. Here’s why flexibility is essential in 3D printing:

- Durability and Impact Resistance: Flexible filaments can absorb impacts that would typically damage rigid materials. This quality makes them perfect for protective gear, sports equipment, and cases for electronics like smartphones and tablets.

- Enhanced Functionality: In medical devices, the soft and adaptable nature of flexible filaments can create more comfortable and adaptable components, such as prosthetics that mimic the flexibility of human skin or organs.

- Innovative Applications: Robotics is another field benefiting immensely from flexible filaments. Robots equipped with parts made from these materials can achieve movements that are smoother and more complex, closely imitating natural motions.

2. Types of Flexible Filaments

Flexible 3D printer filament is revolutionizing the possibilities in 3D printing, offering capabilities that rigid filaments can’t match. Understanding the different types of flexible filaments is crucial for selecting the right material for specific projects. Two of the most popular types of flexible filaments are Thermoplastic Polyurethane (TPU) and Thermoplastic Elastomer (TPE), each with unique properties that cater to different needs in the realm of 3D printing.

TPU (Thermoplastic Polyurethane)

TPU is renowned for its elasticity and mechanical strength, making it a favorite among those who require both flexibility and durability in their prints. Here’s what makes TPU a standout choice:

- High Flexibility and Strength: TPU filaments are highly flexible yet strong, capable of stretching under physical stress without losing their form or breaking.

- Abrasion Resistance: TPU is exceptionally resistant to wear and tear, making it ideal for creating parts that face frequent friction, such as wheels, gears, or protective cases.

- Chemical Resistance: It holds up well against oils, greases, and many chemicals, extending its use to automotive applications and outdoor environments where exposure to such elements is common.

- Applications: Due to its robustness and flexibility, TPU is used in a variety of applications, including but not limited to automotive parts, flexible phone cases, wearable devices, and medical supplies.

TPE (Thermoplastic Elastomer)

TPE stands out for its extreme flexibility and soft touch, which makes it particularly suited for products that require a delicate and adaptable material. Here are some of the characteristics and challenges of TPE:

- Superior Softness and Flexibility: TPE is softer than TPU, which allows it to be used for products that need to mold closely or comfortably against organic shapes, like skin-contact items.

- Challenging to Print: The very soft nature of TPE can make it a challenging material to print with, as it may require specific printer settings and potentially modifications to the printer to handle the material effectively.

- Applications: TPE’s softness makes it ideal for items such as squishy toys, medical devices, and other applications where a gentle, flexible touch is required.

Comparison of TPU and TPE

While both TPU and TPE are flexible, they serve different needs based on their physical properties:

- Durability vs. Softness: TPU offers a balance between flexibility and mechanical strength, making it suitable for structural components that need to endure stress. TPE, however, is softer and more pliable, designed for items that benefit from greater flexibility and a softer feel.

- Chemical and Environmental Resistance: TPU’s resistance to chemicals and environmental factors makes it more suitable for external and automotive parts. TPE is better suited for indoor and skin-contact products due to its softness and flexibility but doesn’t fare as well against harsh chemicals or conditions.

- Ease of Use: TPU is generally easier to print with compared to TPE due to its less extreme flexibility, which means it’s less likely to clog or jam in printers not specifically geared towards soft filaments.

3. Properties of Flexible Filaments

When exploring the capabilities of flexible 3D printer filament, it’s essential to understand the unique properties that make these materials suitable for a wide range of applications. The key properties to consider include flexibility and elasticity, strength and durability, and heat resistance. These characteristics not only define the performance of the filaments in various environments but also guide users in selecting the right type of filament for specific projects.

Flexibility and Elasticity

One of the most significant properties of flexible filaments is their ability to stretch and flex. This is crucial for applications where parts need to absorb shocks or compress and then return to their original form without deforming.

- Shore Hardness: The flexibility of these filaments is typically quantified using a scale known as Shore Hardness. This scale measures the resistance of a material to indentation, with lower numbers indicating softer, more flexible materials. Flexible filaments like TPE can have Shore Hardness values as low as 85A, which is very soft, resembling rubber bands or gel shoe inserts.

- Elasticity: This property allows the filament to stretch significantly before breaking. High elasticity is particularly useful in applications where the material must endure bending and stretching repeatedly without losing its structural integrity.

Strength and Durability

Despite their soft and flexible nature, these filaments are surprisingly robust. Their strength and durability are critical for creating functional parts that must withstand daily wear and tear.

- Impact Resistance: Flexible filaments excel in absorbing impacts, making them ideal for protective applications such as smartphone cases, sports equipment, and even some automotive components.

- Resistance to Wear and Tear: The durability of these materials makes them suitable for creating items like flexible hinges, joints, or machinery parts that experience constant mechanical movements.

Heat Resistance

Heat resistance is another important factor, especially for objects that will be exposed to varying temperatures.

- Temperature Range: Most flexible filaments can withstand temperatures from -20°C to 80°C, making them suitable for many indoor and outdoor applications. This range covers most environmental conditions that products like car parts or consumer electronics might encounter.

- Specialized High-Temperature Filaments: For applications requiring even greater heat resistance, such as parts located near engines or other high-heat areas, specialized flexible filaments can withstand temperatures well above 100°C. These are essential for under-hood automotive components or industrial machinery exposed to high operational temperatures.

Applications Based on Properties

Understanding these properties helps in choosing the right flexible filament for specific applications:

- Consumer Products: For items like wearable devices, flexibility and skin-friendliness are paramount. Filaments with lower Shore Hardness values are preferred.

- Industrial Applications: For parts that require durability under mechanical stress and good heat resistance, a tougher filament like TPU is more appropriate.

- High-Temperature Environments: Specialized filaments are used in settings where regular filaments might degrade due to high temperatures.

4. Choosing the Right Flexible Filament

Selecting the ideal flexible 3D printer filament is crucial for achieving the desired results in your 3D printing projects. Whether you’re a hobbyist or a professional, understanding the factors to consider and knowing which brands to trust can greatly enhance your printing experience. Here, we’ll explore what to look for when choosing a flexible filament and highlight some of the best brands on the market.

Factors to Consider

When choosing a flexible 3D printer filament, several key aspects must be taken into account to ensure compatibility with your project requirements and your printer’s capabilities. Here are the most important factors:

- Elasticity: The degree of elasticity required depends on the application. For items that need to stretch extensively and return to their original shape, such as bands or wearable items, look for filaments with high elasticity ratings.

- Strength: If the printed object must withstand mechanical stresses or bear weight, the filament’s strength becomes a critical factor. This is particularly important for functional parts in automotive applications or mechanical assemblies.

- Environmental Resistance: Consider the conditions under which the item will be used. If the object is to be used outdoors, resistance to UV light, weather conditions, and temperature variations are essential properties to look for.

- Printer Compatibility: Not all 3D printers can handle flexible filaments effectively. Before choosing a filament, ensure that your printer can accommodate such materials. Printers with direct drive extruders typically handle flexible filaments better than those with Bowden extruders. Modifications such as upgrading to a suitable extruder or adding a Teflon tube might be necessary.

- Print Speed and Temperature: Flexible filaments often require specific printing settings, particularly lower speeds and different temperatures compared to more rigid materials. Check the filament’s specifications for optimal print conditions to achieve the best results.

Best Brands on the Market

Several brands have distinguished themselves in the flexible filament market by consistently producing high-quality products that meet the diverse needs of 3D printing enthusiasts and professionals. Here are some of the top brands to consider:

- SUNLU: SUNLU is celebrated for its comprehensive lineup of flexible filaments, which include the highly regarded S-Flex series. Noted for their exceptional elasticity and robustness, SUNLU filaments are preferred by many enthusiasts and professionals for printing flexible objects.

- MatterHackers: Offering a variety of flexible filaments, MatterHackers excels in providing high-quality materials that are compatible with a wide range of printers. They also provide excellent customer support and resourceful guides to help users in selecting and using their products effectively.

- OVERTURE: OVERTURE is well-regarded for its consistent production of high-quality flexible filaments, such as their TPU series. These filaments are acclaimed for their user-friendliness and the superior quality of the finishes they produce on printed items.

5. Preparing for Printing with Flexible Filaments

Printing with flexible 3D printer filament presents unique challenges and opportunities, requiring specific adjustments to your 3D printer setup to ensure success. Proper preparation can make a significant difference in the quality of your prints. Here’s a detailed guide on how to prepare your printer for flexible filaments and ensure optimal printing conditions.

Printer Setup

To achieve the best results with flexible 3D printer filament, your printer setup is crucial. Here are the key considerations:

- Compatibility Check: First, verify that your printer can handle flexible materials. This includes checking for any specific recommendations from the manufacturer regarding flexible filaments.

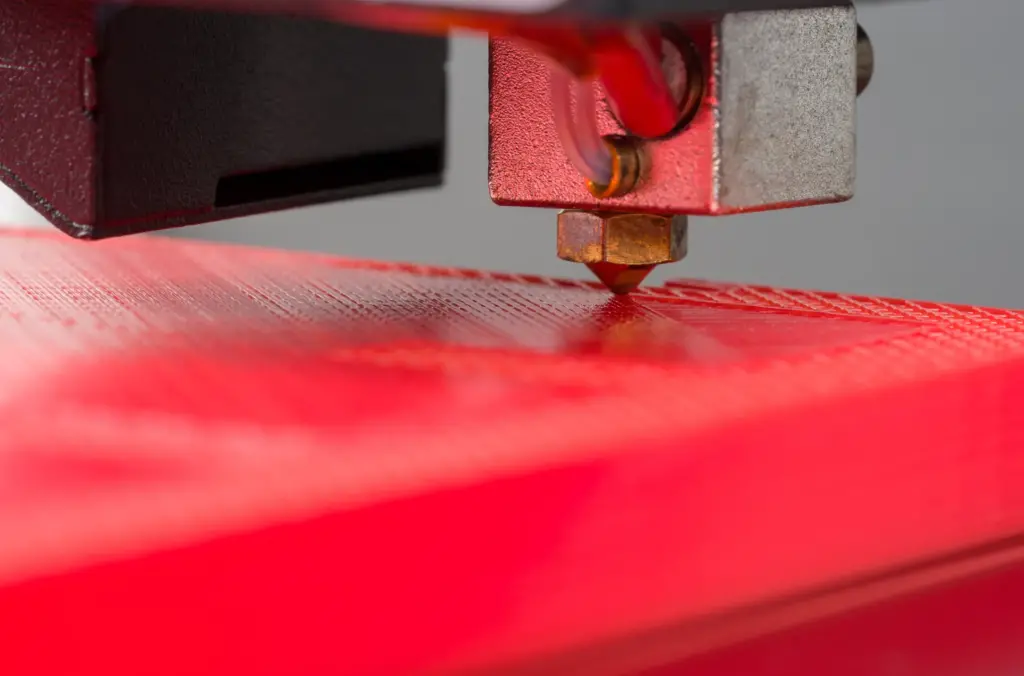

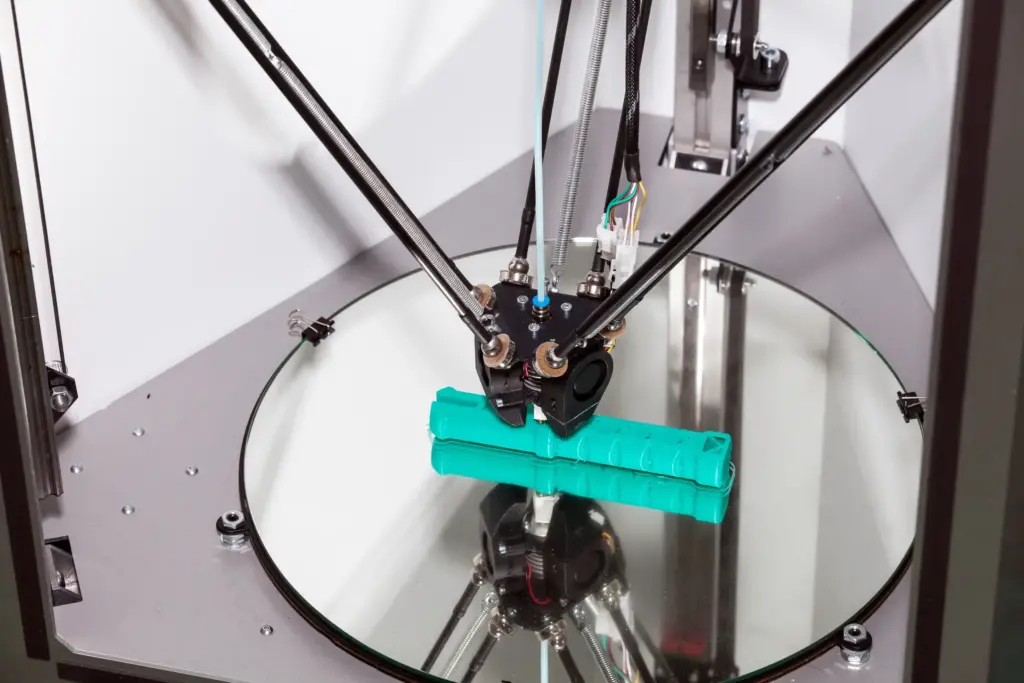

- Extruder Type: Flexible filaments typically perform best with direct drive extruders. These extruders have a short path between the drive gear and the nozzle, which helps prevent the filament from bending and buckling.

- Printing Surface: Using the right build plate surface is essential to prevent warping or misfeeding. Surfaces that provide good adhesion can include PEI sheets, glass with adhesive, or specialized flexible-friendly print beds.

Required Printer Modifications

To optimize your 3D printer for flexible filament, consider these modifications:

- Upgrade to a Direct Drive Extruder: If your printer uses a Bowden extruder, consider upgrading to a direct drive system. This change reduces the distance the filament must travel, providing better control and reducing the likelihood of filament buckling.

- Install a Teflon Tube: Adding a Teflon tube inside the print head can help guide the filament directly into the hot end without any room for bending or clogging.

- Adjust Extruder Tension: Ensure that the extruder tension is properly adjusted to handle flexible filament, which should be enough to push the filament through but not too tight to compress it.

Optimal Printing Conditions

Setting the right conditions for printing with flexible filaments is critical. Here’s how to set up your printer for optimal results:

- Print Speed: Lower print speeds are recommended for flexible filaments, typically around 15-30 mm/s. Slower speeds help ensure more precise extrusion and better adhesion of the material to the build plate.

- Temperature Settings: Flexible filaments often require specific temperature settings which can vary between brands and types. Typically, the extruder temperature should be set between 220°C and 250°C. Always refer to the filament manufacturer’s recommendations for the best results.

- Bed Temperature: Depending on the filament, bed temperatures can range from 40°C to 70°C to help with first layer adhesion without causing warping.

- Retraction Settings: Because of their elasticity, flexible filaments can ooze more than rigid materials. Adjusting retraction settings is crucial—lowering the retraction distance and speed can help minimize issues like stringing.

6. Tips for Successful Printing with Flexible Filaments

Achieving high-quality prints with flexible 3D printer filament can be challenging due to its inherent properties. However, by mastering a few key techniques and understanding the best settings to use, you can significantly improve your printing success. Here are essential tips to guide you in effectively printing with flexible filaments.

Printing Speed and Temperature Settings

Flexible filaments are sensitive to speed and temperature, and setting these parameters correctly is crucial for optimal print quality.

- Printing Speed: Keep the printing speed low to avoid issues like filament buckling inside the extruder. For most flexible filaments, a speed of 20-30 mm/s is recommended. This slower speed allows the filament to feed smoothly and evenly, reducing the risk of errors in the print.

- Temperature Settings: The ideal extrusion temperature for flexible filaments generally ranges between 220°C and 250°C. The correct temperature can vary based on the specific type of filament, so it’s advisable to start at the lower end of this range and adjust if you notice issues with extrusion. Higher temperatures might be necessary for filaments that are particularly thick or tough.

Bed Adhesion Techniques

Good bed adhesion is vital for the first layer of your print, as it sets the foundation for the rest of the object.

- Heated Bed: While not always necessary, using a heated bed can improve the first layer adhesion significantly. Temperatures around 40°C to 60°C can help make the bed sticky enough for flexible filaments without causing them to warp.

- Adhesion Aids: For extra assurance, apply a glue stick, hairspray, or a specialized 3D printing adhesive to the print bed. These substances create an extra sticky layer that helps prevent the print from moving or warping as it cools and contracts.

Dealing with Common Issues

Common problems when printing with flexible filaments include stringing, oozing, and poor bed adhesion. Here’s how to tackle these issues:

- Stringing and Oozing: These occur due to the flexible filament’s tendency to continue oozing out of the nozzle even after the print move has stopped. To combat this, experiment with:

- Retraction Settings: Increase the retraction distance slightly to help pull the filament back during travel moves. However, be cautious as too much retraction can cause clogging.

- Retraction Speed: Adjust the speed at which the filament is retracted. Slower retraction speeds can prevent the filament from being pulled too harshly, which might lead to breakage or clogging.

- Ensuring a Clean and Level Print Bed: A level bed is crucial for uniform first layer adhesion. Make sure the bed is clean from any dust, oils, or previous adhesive residues. Regularly cleaning the bed with alcohol can remove grease and provide a fresh surface for each print.

- Nozzle Health: Check the nozzle before printing to ensure it’s clean and free from any previous material residues. A clean nozzle helps in smooth filament flow, reducing the chances of oozing and stringing.

7. Applications of Flexible Filaments

Flexible 3D printer filament has a vast array of applications that extend across consumer products, industrial needs, and innovative uses. The unique properties of this type of filament make it an ideal choice for projects that require durability, flexibility, and a gentle touch. Here’s a closer look at how flexible filaments are being utilized across different sectors.

Consumer Products

Flexible filaments are increasingly popular for personal and household items due to their versatility and durability. Here are some typical applications:

- Phone Cases: The shock-absorbent nature of flexible filaments makes them perfect for crafting protective phone cases that can withstand drops and bumps.

- Flexible Footwear: From insoles to entire shoes, flexible filaments offer comfort and resilience, accommodating the need for footwear that adapts to the wearer’s movements.

- Ergonomic Grips for Tools: Whether for kitchen utensils, garden tools, or sports equipment, ergonomic grips made from flexible filament provide increased comfort and reduce strain on the user’s hands.

- Protective Gear and Children’s Toys: The soft yet durable nature of these materials makes them ideal for children’s toys that are safe to play with and for protective gear that needs to absorb impacts effectively.

Industrial Applications

In industrial environments, the properties of flexible filaments can be leveraged to enhance the functionality and longevity of various components. Key applications include:

- Seals and Gaskets: These components often need to withstand pressure changes and maintain integrity in harsh environments, making flexible filaments a top choice.

- Hoses and Bellows: The ability of flexible filaments to endure bending and twisting without losing their shape or breaking is crucial for parts like hoses and bellows that transport liquids or gases.

- Non-Slip Surfaces: Tool handles, floor mats, and other surfaces that require a non-slip grip benefit from the texture and flexibility provided by these filaments.

- Chemical Resistance: The resistance of certain flexible filaments to chemicals makes them suitable for use in manufacturing processes that involve corrosive substances.

Unique and Innovative Uses

The potential for creative and innovative applications of flexible filaments is boundless, particularly in fields that benefit from customized solutions.

- Prosthetics: Flexible filaments are used to create prosthetic components that offer comfort and adaptability to the wearer, mimicking the qualities of human skin and muscle flexibility.

- Robotics: In robotics, flexible filaments allow for the creation of parts that need to mimic the movement and flexibility of real limbs, enhancing the robots’ functionality and interaction capabilities.

- Custom Gaskets and Cushioning: Custom parts for specialized machinery or cushioning elements in packaging are increasingly made with flexible filaments due to their adaptability and resilience.

8. Maintaining Your 3D Printer When Using Flexible Filaments

Proper maintenance of your 3D printer is essential when using flexible 3D printer filaments, as these materials can pose unique challenges due to their elasticity and texture. Regular upkeep not only ensures optimal printing performance but also extends the lifespan of your printer. Here, we’ll explore routine maintenance tips and troubleshooting common problems associated with flexible filaments.

Routine Maintenance Tips

Maintaining your 3D printer is crucial for achieving high-quality prints with flexible filaments. Here are some key practices to follow:

- Clean the Extruder Regularly: Flexible filaments can leave residues in the extruder, which may lead to clogs or inconsistent extrusion. Regular cleaning helps prevent these issues.

- Check for Residue and Clogs: After each print, inspect the gear and nozzle to ensure they are free from any filament residues. A clogged nozzle can severely affect your next print’s quality.

- Proper Filament Storage: Flexible filaments are particularly susceptible to moisture, which can degrade the quality of the material and cause issues like bubbling or poor adhesion during printing. Store your filament in airtight containers with desiccant packs to keep it dry.

- Maintain Optimal Tension: The tension on the extruder should be adjusted appropriately for flexible filaments. Too much tension can compress the filament, while too little may lead to slippage and feed problems.

- Update Printer Settings Regularly: As you use different types of filaments, ensure that your printer settings are adjusted accordingly. This includes temperature, speed, and retraction settings tailored to the specific characteristics of flexible filaments.

Troubleshooting Common Problems

When printing with flexible filaments, certain problems may arise more frequently compared to more rigid materials. Here’s how to address these issues effectively:

- Filament Jamming: If the filament jams during printing, check if the extruder is clogged or if the filament has tangled on the spool. Ensure that the filament path is clear and the spool is mounted correctly to avoid tangles.

- Irregular Extrusion: Irregular extrusion can be caused by improper tension in the extruder or by a clogged nozzle. Regularly clean the nozzle and adjust the extruder’s tension to maintain a consistent feed rate.

- Using a Smaller Nozzle: Switching to a smaller nozzle can help improve the precision of prints with flexible filaments. A nozzle with a smaller diameter ensures more controlled extrusion and reduces the likelihood of clogging.

- Print Bed Issues: If the first layer is not sticking well to the print bed, try adjusting the bed temperature, re-leveling the bed, or using adhesion aids like glue or hairspray.

9. Future of Flexible Filaments in 3D Printing

Innovations in Filament Technology

As the demand for more versatile 3D printing materials increases, manufacturers are likely to develop new flexible filaments with enhanced properties such as improved UV resistance, higher temperature thresholds, and greater elasticity without compromising on strength.

Predictions for Market Growth

The market for flexible filaments is expected to grow significantly as both consumers and industries recognize the benefits of using these materials. Advancements in 3D printer technology and filament formulations will continue to expand the range of applications, making flexible filaments a mainstream choice for many printing projects.

10. Conclusion

Flexible 3D printer filaments offer a unique combination of flexibility, durability, and versatility, making them suitable for a wide range of applications from consumer products to industrial components. By understanding the properties and proper handling of these materials, users can effectively harness the potential of flexible filaments.

11. FAQs

- What makes flexible filaments different from standard filaments like PLA or ABS?

Flexible filaments are made from elastomeric materials that allow them to stretch and compress, offering properties like impact resistance and flexibility not found in rigid filaments. - Can any 3D printer use flexible filament?

While many modern 3D printers can handle flexible filaments, some printers might require modifications like installing a direct drive extruder to print effectively with these materials. - Are flexible filaments more difficult to print with than other types?

Yes, due to their elasticity, flexible filaments can be more challenging to print. Proper settings and printer adjustments are crucial for achieving good results. - What are the most common applications for flexible filaments in professional settings?

In professional settings, flexible filaments are often used for creating functional parts like gaskets, seals, and flexible hinges, which require durability and flexibility. - How should I store flexible filament?

Flexible filament should be stored in a cool, dry place, and it is advisable to keep it in an airtight container with desiccants to prevent moisture absorption.

This comprehensive guide covers the essentials of flexible 3D printer filaments, providing practical advice and insight for both newcomers and experienced users.

Resources

- https://www.britannica.com/science/elastomer

- https://filament2print.com/gb/blog/112_5-materiales-innovadores-para-impresi%C3%B3n-3D-FD.html

- https://www.matterhackers.com/store/c/3d-printer-filament