3D Printed Steam Deck Case: A Comprehensive Guide

Ever thought about the endless customization possibilities of a Steam Deck? As a fervent gamer and 3D printing enthusiast, I’ve discovered the magic of combining these worlds. Today, I’m here to share my passion and guide you through crafting your own 3D printed Steam Deck case using both resin and FDM 3D printers. Ready? Let’s dive right in!

Introduction: The World of 3D Printing and Steam Deck

With the introduction of the Steam Deck, gaming got a new portable dimension. But what’s gaming without a bit of personal touch? Enter 3D printing. Imagine your ideal 3d printed Steam Deck case. Got it? Great! Now, let’s bring that vision to life.

Basics of 3D Printing Technology

Resin (SLA/DLP) 3D Printing

Resin printing, also known as SLA/DLP, is all about precision. It works using liquid resin cured by light, resulting in intricate and highly detailed prints. Picture the kind of detail you’d want for game-themed engravings on your case.

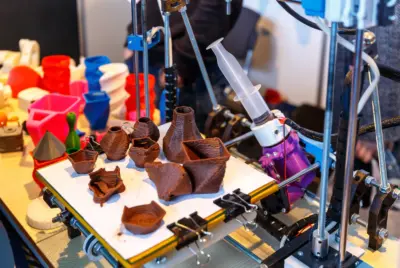

FDM 3D Printing

FDM, on the other hand, is about layering melted material. Think of it as sculpting your Steam Deck case layer by layer. It’s versatile and more common, making it an ideal choice for beginners.

3D Printing Materials: Making the Right Choice for Your Steam Deck Case

Resin 3D Printing Materials

Different resins serve unique purposes, and picking the right one can significantly influence your final product:

- Standard Resin: Great for general purposes, it offers a balanced mix of strength and detail.

- Tough Resin: Best for cases that need to withstand stress or strain. It’s durable and can handle daily wear and tear better than standard resin.

- Flexible Resin: As the name suggests, it’s bendable and compressible, making it perfect for cushioned grips or shock-absorbent designs.

- Castable Resin: This isn’t typically used for cases, but it’s worth mentioning. It’s used for making molds or jewelry.

FDM 3D Printing Materials

Various filaments provide diverse finishes and durability levels:

- PLA: Biodegradable and user-friendly. It’s stiff but can be brittle.

- ABS: Tough and durable with a smooth finish when acetone-treated. However, it can release fumes during printing.

- TPU: Flexible and rubber-like, ideal for shock-absorbing components.

- PETG: Combines the ease of PLA and the strength of ABS, offering a balanced choice for many.

Crafting Your Steam Deck Case with a Resin Printer

Benefits of Using Resin Printers

Resin printers are your go-to if you crave that ultra-smooth finish. These printers allow for high levels of detail, perfect for those intricate designs you might have in mind.

Step-by-Step Guide

- Begin with a clear vision or design.

- Choose a high-quality resin.

- Adjust your printer settings to match the material and desired detail level.

- Monitor the print and ensure consistent curing.

- After printing, wash and cure your case to achieve the best finish.

Designing for 3D Printing: Crafting the Perfect Blueprint

When designing for 3D printing, especially for a functional case like the Steam Deck’s, consider:

- Overhangs: Structures jutting out horizontally. Without proper support, these can sag during printing.

- Supports: Essential for overhangs and complex designs. However, remember they can leave marks when removed.

- Wall Thickness: Too thin might result in breaks, and too thick can waste material and increase print time.

- Software: For beginners, Tinkercad offers an easy start. For more advanced designs, consider Fusion 360 or Blender.

Building a Steam Deck Case with an FDM Printer

Why Choose FDM Over Resin?

FDM is widely accessible and offers a more robust case. Plus, the material variety is vast! Fancy a flexible, rubbery case? FDM has got you covered.

Creating Your Perfect Case

- Start with a blueprint of your design.

- Opt for high-quality filament—PLA or ABS are popular choices.

- Calibrate your printer for optimal layer adhesion.

- Watch out for warping or stringing and adjust settings accordingly.

- Post-process by sanding or painting for a unique touch.

Mastering Post-Processing: The Art Beyond Printing

For Resin Prints:

- UV Curing: Essential for hardening your print. An uneven cure can lead to a tacky surface or warped design.

- Painting/Dyeing: Resin can be dyed before printing or painted afterward. Use acrylics or specialized resin paints for best results.

- Safety: Always wear gloves when handling uncured resin, and clean with isopropyl alcohol.

For FDM Prints:

- Sanding: Helps in smoothing out layer lines. Start with coarser grits (around 200) and work your way to finer ones (up to 1000 or more).

- Acetone Smoothing (for ABS): This technique involves exposing the print to acetone vapors, giving it a glossy finish.

- Painting: PLA and ABS can be painted with acrylics, but ensure the surface is primed first.

Customization and Personalization: Making Your Steam Deck Case Truly Yours

3D printing allows for an unparalleled level of customization, ensuring that your 3d printed Steam Deck case can be a reflection of your personal style:

- Design Additions: Consider adding aesthetic designs like geometric patterns, game-inspired motifs, or even personalized text. Think of adding your gamer tag or favorite game quote.

- LED Lighting: Integrate LED strips or individual LED lights. With some basic electronics, you can create a case that lights up when you’re gaming in the dark.

- Texture: Play around with the surface finish. You can have areas that are smooth, some that are ridged for better grip, or even raised designs for a tactile feel.

- Modular Design: Consider making a case that’s modular. Maybe a detachable stand or replaceable grips for when you’re playing for long hours.

- Integrated Storage: Design a small compartment or slot for storing game cartridges, SD cards, or other accessories.

Resin 3D Printer Recommendations

ELEGOO Mars 3 Pro MSLA 3D Printer

- Pros:

- The 4K Monochrome LCD provides high resolution, enhancing model detail.

- Powerful COB Light Source ensures smooth surface finishes and excellent printing quality.

- Large Build Volume is great for printing large models or batch printing.

- Non-slip hexagon socket leveling screws and sandblasted oxide surface build plate improve adhesion and stability.

- Built-in active carbon filter and efficient cooling system enhance the user experience.

- Cons:

- The cost of shipping and import fees to certain locations, like Brazil, can be quite high.

- Some users might find the printer size and weight (13.7 Pounds) a bit cumbersome.

ANYCUBIC Photon Mono M5s 12K Resin 3D Printer

- Pros:

- 12K resolution on a 10.1-inch screen allows for extremely detailed prints.

- Leveling-Free feature simplifies the setup process.

- Fast printing speed with high-speed resin.

- Intelligent and efficient with auto device check, resin detection, and upgraded slicer software.

- Cons:

- Higher price point.

- Weighs more (19.6 Pounds), which could be an issue for some users.

FDM 3D Printer Recommendations

Official Creality Ender 3 V2 Neo 3D Printer

- Pros:

- Easy assembly with a mostly pre-installed setup.

- CR Touch Auto Bed Leveling for convenience.

- Upgraded UI with model preview function.

- Innovative PC spring steel magnetic build plate for easy model removal.

- Silent motherboard for a quieter operation.

- Cons:

- Smaller build volume compared to some competitors.

- The initial cost might still be a barrier for budget-conscious consumers.

Artillery Sidewinder X2 3D Printer

- Pros:

- Direct Drive Extruder reduces filament clogging and improves print quality.

- Dual Z-Axis Synchronization System enhances printing precision.

- Automatic Leveling for ease of use.

- Resume Printing Function is useful in case of power failures.

- Ultra-Silent Printing is great for night-time operations.

- Cons:

- Bulky size might not be suitable for limited spaces.

- Shipping and import fees can significantly increase the cost for international buyers.

Pro Tips for a Successful Printing Experience

3D printing can seem daunting, but with a few professional tips up your sleeve, you can navigate the process with ease and achieve better results:

- Layer Height Adjustments: For detailed models, use a smaller layer height. For faster prints that don’t require fine detail, a larger layer height can be utilized.

- Orientation Matters: The way your model sits on the print bed can affect support needs, print time, and the final look. Experiment with different orientations to see what works best.

- Temperature Control: Ensure that the room where you’re printing is free from drafts and remains at a consistent temperature, especially important for materials like ABS.

- Regular Calibration: Periodically calibrate your printer for consistent results, focusing on bed leveling and nozzle alignment.

- Test Prints: Before committing to a large print, do smaller test prints to verify settings and save on materials.

- Keep Firmware Updated: Manufacturers often release updates that can improve printer performance or rectify known issues.

- Use Quality Materials: Not all filaments or resins are created equal. Investing in reputable brands can lead to better print quality and fewer issues.

Cost Analysis: Ensuring Value for Every Penny Spent

A 3d printed Steam Deck case can be cost-effective, but it’s essential to understand where your money goes:

Material Costs:

- Resin: Typically, resin can be more expensive than FDM filaments. The type of resin (Standard, Tough, Flexible) can also influence the cost.

- FDM Filaments: Among FDM materials, PLA is usually the cheapest, while specialized materials like TPU or PETG might cost more.

Printer Wear and Tear: 3D printers have parts that wear out over time. Consider the cost of replacement parts like FEP films for resin printers or nozzles for FDM printers.

Electricity Consumption:

- Resin Printers: Typically use UV LEDs, which are relatively energy efficient.

- FDM Printers: The heating element for the nozzle and heated bed can consume a significant amount of electricity, especially for long prints.

Post-Processing Costs: Materials like paints, sandpaper, or even acetone (for ABS smoothing) add to the overall expense.

Failed Prints: Not every print will be successful. Factor in the cost of wasted materials and electricity from failed attempts.

Design Software: While there are many free design software options available, advanced software may come with subscription fees.

Maintaining Your 3D Printer: The Key to Consistency

Regular maintenance ensures longevity and consistent results:

For Resin Printers:

- Clean the Vat: After every print, ensure no cured bits are left in the vat.

- Replace the FEP Film: Over time, the film at the bottom of the vat can get cloudy or damaged.

For FDM Printers:

- Clean the Nozzle: Avoid clogs by regularly cleaning the nozzle.

- Bed Calibration: Ensure the print bed is level. An uneven bed can lead to failed prints.

Troubleshooting Common Issues: Because Perfection Requires Patience

3D printing isn’t always smooth sailing:

Warping: Especially common with ABS. Ensure a heated bed, and consider using brims or rafts.

Stringing: Occurs when the nozzle moves between points, leaving thin strands. Adjust retraction settings.

Layer Shifting: Usually a hardware issue. Ensure the printer’s belts are tight and that the device is on a stable surface.

Failed Supports: If supports fail to print, consider increasing their density or redesigning the model to reduce overhangs.

Conclusion: Stepping into the Future with Your Steam Deck Case

We’ve ventured through the realms of 3D printing and gaming. Now, with a wealth of knowledge, the power to create your dream 3d printed Steam Deck case lies in your hands. Remember, it’s all about personal expression. So, what will your case say about you?

FAQs

- Can I mix and match FDM and resin parts for my case?

Absolutely! Get creative and combine the best of both worlds. - How long does it take to print a case?

It varies depending on your design and printer settings. Typically, several hours to a day. - Do I need special software?

Most printers come with recommended slicing software. Explore options like Cura or PrusaSlicer. - Is 3D printing safe?

Generally, yes. However, always work in a well-ventilated area and follow safety guidelines. - Can I sell my custom-designed cases?

If you’ve created the design yourself and it doesn’t infringe on any copyrights, why not? Share your creativity with the world!

Resources

- https://www.tinkercad.com/

- https://www.autodesk.com/products/fusion-360/personal

- https://www.blender.org/

- https://ultimaker.com/software/ultimaker-cura/

- https://www.prusa3d.com/page/prusaslicer_424/

- https://tweakyourbiz.com/posts/6-tips-to-build-a-successful-printing-business