How to Remove Supports from 3D Prints: Master Clean Finishes with Ease

I. Introduction

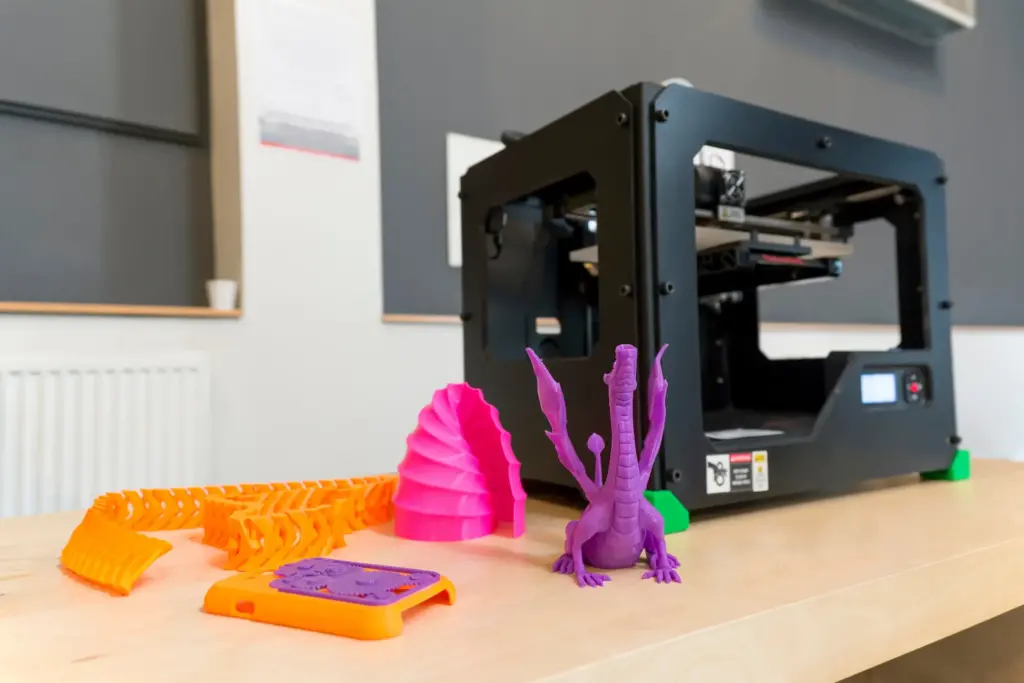

Hello fellow 3D printing enthusiasts! As you explore the realm of 3D printing, you’ve probably encountered the necessity for supports in your projects. These structures are crucial for creating overhangs and intricate designs. However, once the printing completes, figuring out how to remove supports from 3D prints can be challenging. This guide aims to assist you through the process, ensuring your final product is as polished and flawless as possible.

II. Understanding Supports in 3D Printing

In the world of 3D printing, supports play a pivotal role in ensuring the integrity and accuracy of your prints. As temporary structures, they provide necessary support to overhanging parts and complex geometries that would otherwise be impossible to print due to the limitations of gravity and material properties. When learning how to remove supports from 3D prints, it’s essential to first understand the different types of supports you might encounter.

Types of Supports in 3D Printing

Support structures can be broadly categorized into two main types: breakaway supports and dissolvable supports. Each type serves a specific purpose and requires a different approach for removal.

Breakaway Supports

Breakaway supports are the most common type used in 3D printing. Here are some key features and removal tips:

- Design and Function: Designed to mechanically support the model during the print, they are not strongly bonded to the surface, which facilitates easier removal post-printing.

- Removal Process:

- Tools Required: Typically, tools like tweezers, pliers, or even just your fingers are sufficient.

- Technique: Gently wiggle or twist the supports away from the model. For tougher supports, carefully use a craft knife to help pry them off without damaging the model.

- Finishing Touches: After removal, minor sanding or filing might be necessary to smooth out the points where supports were connected.

Dissolvable Supports

For models with extremely intricate details and delicate overhangs, dissolvable supports are ideal. Understanding their composition and removal process is crucial:

- Material Composition: Unlike breakaway supports, dissolvable supports are made from a material that can dissolve in a specific chemical solvent, such as limonene for HIPS (High Impact Polystyrene) or plain water for PVA (Polyvinyl Alcohol).

- Dissolution Process:

- Preparing the Solvent Bath: Ensure the solvent is appropriate for the support material. The bath should be well-ventilated and at a controlled temperature to optimize dissolution.

- Time Frame: The time it takes for the supports to dissolve can vary from a few hours to overnight, depending on the material and the volume of supports.

- Post-Removal Care: Once supports are dissolved, thoroughly rinse the model under running water to remove any residual solvent and prevent any potential weakening of the model structure.

III. Preparing for Support Removal

When you embark on the task of removing supports from your 3D prints, preparation is key. Not only does it streamline the process, but it also ensures the safety and quality of your final product. Here’s how to properly prepare for this crucial step in the post-processing of 3D printed items, ensuring you know exactly how to remove supports from 3D prints safely and effectively.

Essential Tools for Support Removal

To efficiently and safely remove supports from your 3D prints, you’ll need to gather a few essential tools. Each tool has a specific role in making the removal process smoother and preventing damage to your printed model.

- Tweezers: Ideal for removing small and finely placed support structures without applying too much pressure on the model.

- Needle-Nose Pliers: These are perfect for grasping larger support structures. Their long, thin shape allows you to reach into tight spaces without disturbing the surrounding print.

- Craft Knife: A sharp craft knife is useful for cutting away stubborn supports that are not easily plucked or twisted off. It must be used with care to avoid cutting into the actual model.

- Safety Glasses: Protecting your eyes should be a priority, as removing supports can sometimes send small pieces flying unexpectedly.

Setting Up Your Workspace

The environment in which you remove supports can significantly affect the ease of the task and the safety of both the user and the 3D print. Here are some tips to set up an ideal workspace:

- Well-Lit Area: Good lighting is crucial as it helps you see the supports clearly and distinguish them from the model itself, reducing the risk of accidentally damaging your print.

- Stable Work Surface: Use a sturdy table or bench to work on so that your model is secure and doesn’t shift during the support removal process.

- Protective Gear: Apart from safety glasses, consider wearing gloves to protect your hands from sharp tools and rough edges of the supports.

- Organized Tool Placement: Keep your tools neatly arranged and within easy reach to streamline your workflow and reduce the risk of accidents.

Safety Precautions

Taking the right safety precautions is essential not only to protect yourself but also to ensure the integrity of your 3D print:

- Handle Tools with Care: Always use tools according to their intended purpose and handle them carefully, especially sharp instruments like craft knives.

- Wear Appropriate Gear: Safety glasses are a must, and depending on the complexity and size of the supports, gloves can also be advisable to prevent scratches or cuts.

- Maintain Focus: Always pay attention to the task at hand. Distractions can lead to accidents or damage to your print.

IV. Removing Breakaway Supports

When it comes to 3D printing, the removal of breakaway supports is a crucial step to ensure the final product is smooth and aesthetically pleasing. This type of support is specifically designed to be easily removed without specialized equipment, making them a convenient option for many projects. However, knowing how to remove supports from 3D prints correctly is essential to avoid damaging the intricate details of your print. Here’s a detailed guide to removing breakaway supports efficiently and safely.

1-Step: Initial Assessment

Before you begin the actual removal process, it’s important to thoroughly assess your 3D print:

- Identify Support Locations: Carefully examine your print to determine where the supports have been placed. This will help you understand the structure and how these supports are interacting with your model.

- Evaluate Attachment Points: Look at how the supports are connected to the model. This can vary greatly depending on the design and orientation of the print. Understanding these connections will guide you in choosing the right tool and technique for removal.

2-Step: Tools and Techniques for Effective Support Removal

Choosing the right tools and applying the correct techniques are key to removing breakaway supports without causing damage to your model:

- Tweezers: These are perfect for removing small and fine supports. Use a gentle grip and a steady hand to pull the supports away from the model, minimizing pressure on the print itself.

- Needle-Nose Pliers: When dealing with larger support structures, needle-nose pliers can be very effective. They allow for a firm grip and provide the leverage needed to remove supports that are more robust or tightly attached.

- Craft Knife: In cases where supports are flush against the model or are in hard-to-reach areas, a craft knife can be invaluable. Carefully slide the blade between the support and the model to slice through the connection. Always cut away from your body and keep the knife’s movement parallel to the surface of the model to prevent nicks or cuts in the print.

3-Step: Finishing Touches

Once all the supports are removed, the final step is to refine the appearance and texture of your print:

- Sanding: Use fine-grit sandpaper to smooth any rough edges left by the supports. Sand gently in a circular motion over the areas where supports were attached. This will help achieve a smooth, uniform finish.

- Inspect and Touch Up: After sanding, inspect your model for any residual marks or minor imperfections. Additional light sanding might be needed if any rough spots remain.

- Cleaning: Wipe down the model with a soft, dry cloth to remove any dust or debris from the sanding process, ensuring that your finished product looks clean and professional.

V. Working with Dissolvable Supports

Dissolvable supports offer a unique advantage in 3D printing, particularly for complex models where removing physical supports could risk damaging the print. These supports are made from materials that can be dissolved away in specific solvents, making the post-processing cleaner and less risky. Understanding how to remove supports from 3D prints when they are dissolvable involves several crucial steps and knowledge of the appropriate chemicals.

Understanding the Solvents

Each type of dissolvable support material requires a specific solvent for effective dissolution:

- PVA (Polyvinyl Alcohol): Commonly used with PLA prints, PVA supports dissolve in water, making it one of the safest and easiest solvents to handle.

- HIPS (High Impact Polystyrene): Often paired with ABS printing, HIPS requires limonene, a citrus-based solvent, to dissolve. This solvent is more specialized and requires careful handling due to its stronger chemical properties.

The choice of solvent is crucial as using the wrong type can damage the print or be ineffective at dissolving the supports.

Step-by-Step Dissolution Process

Successfully removing dissolvable supports involves a detailed process to ensure complete removal without harming the print.

Preparing the Solvent Bath

- Temperature Control: Ensure that the solvent is at the optimal temperature for dissolution, which varies depending on the support material. For instance, warm water can accelerate the dissolution of PVA but should not be too hot to prevent warping or damaging the primary material.

- Solvent Quantity: Use enough solvent to completely submerge the print, allowing uniform dissolution of all support structures.

Monitoring and Agitation

- Regular Checking: Monitor the dissolution process periodically to ensure that the supports are dissolving evenly and to check on the progress of the solvent action.

- Agitation: Gently agitate the solvent bath to prevent any pockets of undissolved support material from forming around the print. This can be done by lightly stirring the bath or using ultrasonic cleaners if available.

Post-dissolution Cleaning

- Thorough Rinsing: Once the supports are completely dissolved, remove the print from the solvent bath. Thoroughly rinse the print under running water to remove any traces of the solvent, which prevents potential irritation or damage to the print’s surface.

- Drying: Allow the print to dry completely. Residual moisture can be dabbed gently with a soft, lint-free cloth or allowed to air dry.

Safety Tips

Working with chemical solvents, especially those like limonene, requires precautions to ensure safety:

- Ventilation: Work in a well-ventilated area to avoid inhalation of fumes.

- Protective Wear: Wear gloves and eye protection to prevent skin and eye contact with the solvent.

- Proper Disposal: Dispose of used solvents according to local regulations to ensure environmental safety.

VI. Tips for a Smooth Removal of Supports from 3D Prints

Removing supports from 3D prints can be a delicate task, especially when dealing with intricate models and fragile areas. To ensure a smooth and safe removal process, here are some expert tips and techniques that will help you maintain the integrity and appearance of your 3D prints.

Temperature Tips for Easing Support Removal

Proper use of temperature can significantly ease the removal of support structures, particularly when dealing with materials that respond well to heat:

- Gentle Heat Application: Using a heat gun or hair dryer set on low can gently warm the supports, making them more pliable and easier to remove. This technique is particularly useful for thick or stubborn supports.

- Controlled Environment: Keep the room temperature consistent. Extreme cold can make some materials brittle and more prone to snapping, while excessive heat can soften the model too much.

- Heat Responsively: Apply heat evenly and cautiously. Direct the heat source in a sweeping motion to avoid concentrating too much heat in one area, which could deform the print.

Handling Delicate Parts

When removing supports from areas that are thin, intricate, or otherwise delicate, special care is necessary to prevent damage:

- Use Fine Tools: Opt for precision tools like fine tweezers or dental picks for delicate operations. These allow for more controlled and gentle manipulation.

- Stabilize the Model: Support the model adequately while removing supports. Hold the part of the model that is being worked on firmly but gently to minimize stress on the material.

- Sequential Removal: Start removing supports from the easiest, least delicate parts to reduce overall tension and avoid pulling on delicate sections unexpectedly.

Advanced Post-processing Techniques

After the supports are removed, further post-processing may be needed to achieve a smooth and high-quality finish:

- Sanding: Use fine-grit sandpaper to smooth out the surfaces where supports were attached. Begin with a coarser grit to remove any major imperfections, and finish with a finer grit for a smooth surface.

- Heat Gun or Chemical Smoothing: For materials like ABS, lightly applying a heat gun can help relax minor imperfections. Alternatively, techniques like acetone vapor smoothing can be used to achieve a glass-like finish on ABS prints.

- Fill and Refine: For visible marks left after support removal, use a filler (like a putty or resin appropriate for your print material) to fill any gaps, then sand and possibly paint the area if necessary.

VII. VII. Troubleshooting Common Issues in Removing Supports from 3D Prints

Even with meticulous planning and careful execution, removing supports from 3D prints can sometimes present challenges. Whether you’re facing broken pieces, incomplete dissolution of dissolvable supports, or rough surfaces post-removal, understanding how to effectively troubleshoot these issues is crucial. Here, we explore solutions to some common problems encountered when learning how to remove supports from 3D prints, ensuring your projects achieve a professional finish.

Dealing with Broken Pieces

Breaking parts of your model during support removal is a common issue, particularly with intricate designs or when using brittle materials.

- Preventative Measures: Ensure that your print settings, such as layer height and print speed, are optimized for strength. Consider increasing the infill percentage or adjusting the orientation of the print to enhance structural integrity.

- Repair Techniques: If breakage occurs, you can often repair the model using a suitable adhesive. For plastics like PLA or ABS, cyanoacrylate (super glue) is typically effective. Apply a small amount to both surfaces, press together, and hold until set. For a seamless repair, you might also use a 3D pen to fill gaps with matching filament.

Addressing Incomplete Dissolution

When dissolvable supports do not fully dissolve, it can leave residues on your print, affecting both aesthetics and functionality.

- Optimize Solvent Bath: Ensure the solvent is fresh and at the correct temperature. Some materials may require warmer temperatures to dissolve efficiently.

- Agitation: Increase agitation in the solvent bath. Use a gentle swirling action or a specialized ultrasonic cleaner to help break down stubborn support material.

- Extended Soak Times: Allow the print to soak for longer periods, checking periodically to see if the supports have fully dissolved. Be cautious not to overexpose the print to the solvent, as this could weaken the structure.

Smoothing Rough Surfaces After Support Removal

Rough surfaces where supports were connected to the model are another common challenge. Achieving a smooth finish can greatly enhance the visual quality of your print.

- Gradual Sanding: Start with a coarser grit sandpaper and gradually move to finer grits. This methodically reduces the roughness without removing too much material.

- Chemical Smoothing: For materials like ABS, chemical smoothing with acetone vapor can be effective. This technique melts the outer layer slightly, leading to a smooth finish. Ensure this is done in a well-ventilated area with appropriate safety equipment.

- Fill and Sand Method: For extremely rough spots, apply a spot putty or filler designed for 3D prints, then sand it down once dry. This can help achieve a level surface that blends seamlessly with the rest of your model.

VIII. Maintaining Your 3D Printer After Support Removal

After the task of removing supports from your 3D prints, maintaining your 3D printer is crucial to ensure it continues to operate efficiently and produces high-quality prints. Routine maintenance not only prolongs the life of your printer but also prevents issues that can arise from leftover material residues.

Cleaning the Build Plate

The build plate is where your objects are printed and can often have residual adhesive or small fragments of support material left behind.

- Removing Residue: Use a scraper to gently remove any leftover pieces of support material or adhesive from the build plate. Be careful to avoid scratching the surface.

- Cleaning Solution: Apply a mild cleaning solution appropriate for your build plate’s material. For glass plates, isopropyl alcohol is effective for removing grease and residues.

- Wipe Down: Use a soft, non-abrasive cloth to wipe the build plate clean. Ensure it is completely dry before you commence another print job.

Checking and Cleaning the Extruder

The extruder is responsible for feeding filament to the hot end and can become clogged with small fragments of filament from support structures.

- Visual Inspection: Regularly inspect the extruder for any signs of filament debris or wear. Look for any filament strands that may be obstructing the path.

- Cleaning the Gear: Use a small brush (like an old toothbrush) to clean out any debris from the gears of the extruder. This prevents filament slippage and ensures smooth extrusion.

- Nozzle Check: Make sure the nozzle is clear of obstructions. A clogged nozzle can be cleaned using a fine needle, but be sure to heat the nozzle first to soften any lodged material.

Lubricating Moving Parts

To ensure smooth operation, it’s important to lubricate the moving parts of your printer periodically.

- Identify Lubrication Points: Check your printer’s manual to identify the parts that require lubrication, such as rods, bearings, and screws.

- Apply Lubricant: Use a suitable lubricant recommended for your printer. Apply sparingly to avoid attracting dust and debris.

- Movement Check: Move the printer’s components through their full range of motion to distribute the lubricant evenly.

Updating Software

Keeping your printer’s firmware and software updated is crucial for optimal performance.

- Check for Updates: Regularly check the manufacturer’s website or your printer’s interface for any firmware updates.

- Install Updates: Follow the manufacturer’s instructions to update the printer’s firmware. This can include improvements in printing accuracy and support material processing.

Regular Calibration

To ensure your prints come out perfectly every time, regular calibration of the printer is necessary.

- Level the Build Plate: Make sure the build plate is perfectly level. An uneven build plate can lead to adhesion problems and affect the quality of your prints.

- Calibrate Extrusion: Perform a calibration print to check that the amount of material extruded is accurate. Adjust the extruder multiplier if necessary.

IX. Advanced Techniques and Tools for Removing Supports from 3D Prints

As 3D printing technology evolves, so do the methods and tools available for post-processing, including the removal of support structures. For enthusiasts and professionals seeking more efficient and less labor-intensive ways to remove supports from 3D prints, advanced techniques and tools can significantly streamline the process.

Specialized Support Removal Systems

Investing in specialized support removal systems is an excellent option for those who frequently work with 3D printed objects, particularly in a commercial or industrial setting.

- Automated Support Removal Machines: These systems are designed to remove supports from 3D prints using various methods, including mechanical, chemical, or thermal processes. They are especially useful for handling large volumes of prints or prints with complex support structures that would be tedious to remove manually.

- Benefits: Such machines can reduce the amount of time spent on post-processing, minimize the risk of damaging prints during support removal, and ensure a consistent finish across multiple items.

- Considerations: While highly effective, these systems can be a significant investment, so they are best suited for high-output environments or where precision is paramount.

Precision Tools for Detailed Work

For detailed and delicate work, precision tools can provide the control and finesse required to achieve clean, support-free surfaces without compromising the integrity of the print.

- Rotary Tools (e.g., Dremels): Rotary tools offer a versatile solution for removing supports from 3D prints. With various attachments, such as grinding bits and cutting wheels, these tools can remove supports from hard-to-reach areas and fine-tune the surfaces of prints.

- Laser Cutting and Ablation: Some advanced setups use laser technology to precisely cut away support material without touching the actual print, providing an extremely precise method to clear away supports with minimal contact.

- Ultrasonic Removal: Ultrasonic cutters can precisely slice through support material by vibrating at high frequencies. This method is particularly effective for intricate designs where traditional cutting tools might pose a risk of damage.

Integrating Advanced Technologies

Incorporating advanced technologies can further enhance the support removal process:

- 3D Scanning and Software Solutions: Utilizing 3D scanning to map the exact layout of supports and employing software to plan the removal process can optimize the sequence of steps and reduce the manual effort required.

- AI-Powered Systems: Some cutting-edge systems use artificial intelligence to automatically identify and navigate the removal of support structures, adapting their techniques to the specific needs of each print.

X. Conclusion

Removing supports can be as much an art as it is a science. With practice and patience, you’ll improve your skills and achieve better results with each print.

XI. FAQs

- What’s the best way to remove supports without damaging my print?

Use appropriate tools like tweezers and pliers gently and follow the specific removal steps. - How long should I leave my print in the solvent bath?

Until the supports dissolve completely, usually a few hours, but monitor regularly. - What are some safety tips for working with chemical solvents?

Wear gloves, goggles, and ensure adequate ventilation. - Can heat help in removing supports?

Yes, gentle heat can soften supports, making them easier to remove. - How do I know if my print needs supports?

If your design has overhangs or complex geometries, supports are likely necessary.

This detailed guide should equip you with the knowledge and techniques to effectively remove supports from your 3D prints, ensuring clean, professional results. Happy printing!

Resources

- https://camachem.com/en/blog/post/frequently-asked-question-about-poly-vinyl-alcohol-pva

- https://www.polymershapes.com/product/high-impact-polystyrene-hips/