3D Printing Problems: Master the Art of Flawless Printing with These Expert Solutions!

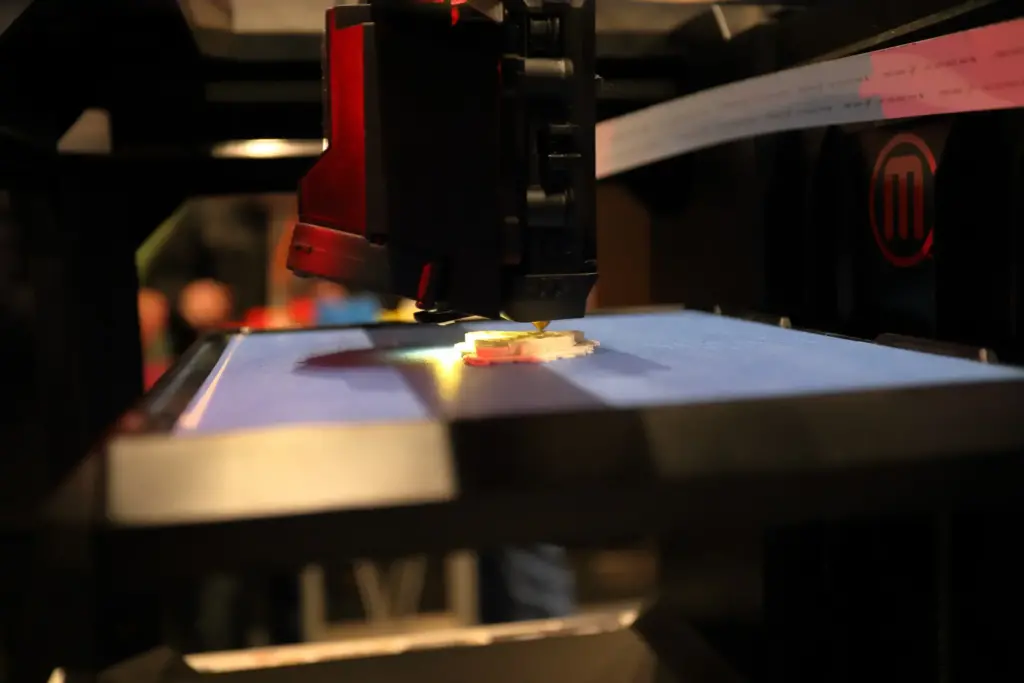

1. Introduction

3D printing, a transformative approach to manufacturing and prototyping, is increasingly accessible to enthusiasts and professionals alike. However, mastering this technology comes with its challenges. In this guide, I’ll walk you through common 3D printing problems, offer solutions, and tell you when it’s time to seek professional help.

2. Common 3D Printing Problems

When delving into the world of 3D printing, understanding and addressing common issues is crucial to achieving successful prints. Here, we’ll explore some of the most frequent hurdles: Warping, Nozzle Clogging, and Stringing. By gaining insights into these problems, you can ensure smoother and more reliable 3D printing experiences.

Warping

Warping is a prevalent issue in the realm of 3D printing, particularly distressing because it can severely distort the shape and quality of your final print. This phenomenon occurs when different parts of your print cool at different rates, causing the corners of the print to lift and detach from the build plate. Here are detailed steps to mitigate warping:

- Use a Heated Bed: Increasing the temperature of the build plate can help the first layers of your print remain warm and malleable, reducing stress and preventing lifting.

- Apply an Adhesive: A glue stick, hairspray, or dedicated 3D print bed adhesive can increase the grip of the first layers on the build plate.

- Enclosure Installation: An enclosure around your 3D printer stabilizes the temperature and shields the print from drafts, which are a common cause of warping.

- Level the Bed: An uneven bed can exacerbate warping. Ensure that your printing bed is as level as possible.

Nozzle Clogging

A clogged nozzle can interrupt your printing process, leading to incomplete prints or poor-quality outcomes. Filament particles can burn inside the nozzle, or debris can accumulate, leading to a blockage. To tackle nozzle clogging effectively:

- Regular Cleaning: Perform regular maintenance checks and clean the nozzle to remove any residual or burnt filament. A needle or fine wire can be used to clear the nozzle.

- Proper Filament Storage: Store your filament in a cool, dry place to prevent moisture uptake, which can lead to filament degradation and clogging.

- Temperature Adjustments: Ensure the nozzle is heated to the correct temperature for the specific type of filament being used, as incorrect temperatures can cause the filament to burn or not melt properly.

Stringing or Oozing

Stringing occurs when small strings of plastic are left between different parts of your print, which happens when the nozzle oozes excess plastic during movement. Although not detrimental to the function of the print, it affects the aesthetic quality and requires post-processing to remove. Effective strategies to reduce stringing include:

- Optimize Retraction Settings: Retraction pulls the filament back into the nozzle when moving across open spaces. Adjusting the retraction speed and distance can help minimize oozing.

- Temperature Adjustment: Lowering the nozzle temperature can reduce the fluidity of the melted filament, decreasing the likelihood of oozing.

- Travel Speed: Increasing the travel speed of the nozzle can help reduce the time it takes to move between points, thus lessening the opportunity for stringing.

3. In-depth Problem Analysis

Dealing with “3D Printing Problems” can be frustrating, but a deeper understanding of each issue will equip you with the necessary tools to manage and overcome these challenges effectively. Let’s delve deeper into three common issues: Warping, Nozzle Clogging, and Stringing or Oozing.

Warping

Warping is one of the most common “3D Printing Problems,” where the corners of the print lift off the printing bed, leading to a deformed final product. This issue typically arises due to temperature fluctuations and poor bed adhesion.

Causes and Prevention of Warping:

- Temperature Control: Maintain a consistent temperature throughout the printing process. Fluctuations can cause the material to contract unevenly, leading to warping.

- Heated Bed: Utilizing a heated bed ensures the first layers of the print remain warm, reducing the likelihood of warping. Temperatures should be adjusted according to the material used.

- Draft-Free Environment: Ensure your printing environment is free from drafts or sudden air movements. Even a slight change in room temperature can impact print quality.

- Use of Enclosures: Enclosures can help maintain a stable temperature and protect the print from environmental factors that contribute to warping.

- Adhesion Techniques: Applying adhesives like glue sticks, hairspray, or dedicated 3D print bed adhesives can significantly improve the first layer’s adherence to the build plate.

Nozzle Clogging

Another frequent issue is nozzle clogging, which disrupts the printing process by blocking the extrusion path of the filament, resulting in inconsistent extrusion and missed layers.

Managing Nozzle Clogs:

- Regular Maintenance: Keep the nozzle clean by performing regular maintenance. This involves manually cleaning the nozzle with a needle or using specialized cleaning filaments designed to remove residue inside the nozzle.

- Proper Filament Storage: Filament should be stored in a cool, dry place to prevent the absorption of moisture, which can degrade the filament and contribute to clogging.

- Correct Temperature Settings: Ensure that the nozzle is heated to the right temperature for the specific filament used to avoid underheating (leading to incomplete melting) or overheating (which may cause burning and clogging).

Stringing or Oozing

Stringing or oozing occurs when excess filament oozes out of the nozzle as it moves across non-print areas, creating thin strings between parts of the print.

Solutions for Stringing and Oozing:

- Retraction Settings: Properly configuring retraction settings can greatly reduce stringing. Retraction pulls the filament back into the nozzle during travel moves to prevent oozing.

- Temperature Optimization: Lowering the printing temperature can help minimize oozing, as the filament is less liquid at lower temperatures.

- Increase Travel Speed: By increasing the speed at which the nozzle moves between print areas, there is less time for the filament to ooze.

4. Advanced 3D Printing Challenges

As you delve deeper into the world of 3D printing, you might encounter some sophisticated challenges that can significantly affect the quality and success of your prints. “3D Printing Problems” such as Layer Shifting and Under-extrusion are particularly troublesome as they often stem from mechanical inaccuracies and calibration issues. Addressing these problems requires a nuanced understanding and a proactive maintenance regimen.

Layer Shifting

Layer Shifting is a disruptive issue where the layers of your print do not align correctly, resulting in a misshapen or skewed output. This misalignment can severely detract from the aesthetic quality of your prints and compromise their structural integrity.

Understanding the Causes of Layer Shifting:

- Mechanical Issues: Loose belts or gears, worn-out bearings, or unstable printer frames can lead to improper movement of the print head or build plate.

- Electrical Problems: Stepper motors losing steps due to insufficient current or electrical interference can also cause layer shifts.

- Software Settings: Incorrect settings in your printer’s firmware or slicing software might lead to speeds and accelerations that are too aggressive for stable printing.

Solutions for Layer Shifting:

- Tighten and Align: Regularly check and tighten all belts and pulleys. Ensure that all mechanical parts are aligned and moving smoothly.

- Adjust Motor Settings: Increase the current to the stepper motors slightly if they are losing steps, but be cautious of overheating.

- Optimize Printing Parameters: Lower the printing speed and acceleration settings in your slicing software to reduce the stress on the printer’s mechanical components.

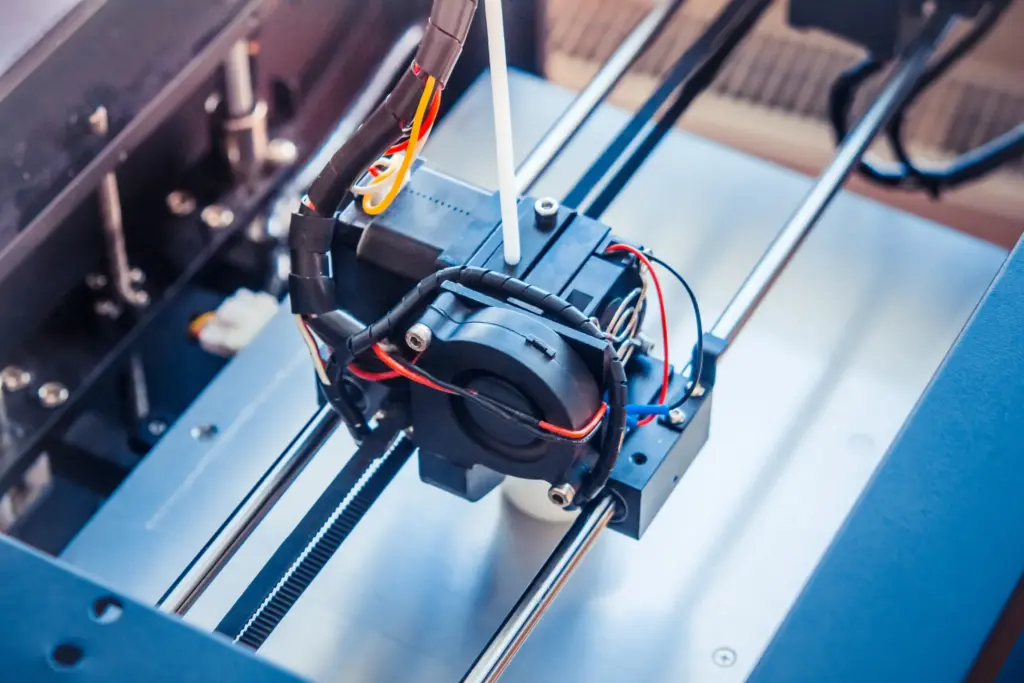

Under-extrusion

Under-extrusion occurs when your printer fails to deposit enough filament, leading to prints that are weak, have thin walls, or are missing layers entirely. This can be due to a number of factors ranging from filament quality to extruder hardware issues.

Pinpointing Causes of Under-extrusion:

- Filament Quality: Poor quality or incorrectly sized filament can lead to inconsistent extrusion.

- Extruder Issues: Worn out extruder gears, incorrect tension on the filament, or a clogged nozzle can restrict filament flow.

- Printing Environment: Environmental factors such as temperature and humidity can also affect filament behavior and extrusion consistency.

Addressing Under-extrusion:

- Ensure High-quality Filament: Use well-reviewed and appropriate filament for your printer to avoid quality issues that could lead to under-extrusion.

- Maintain the Extruder Assembly: Regularly clean and inspect the extruder’s gears and nozzle. Replace any worn components as needed.

- Adjust Print Settings: Check that the extruder temperature is adequate for the material being printed. Adjust flow rate settings in your slicing software to compensate for any discrepancies in filament diameter.

5. Troubleshooting Techniques for 3D Printing Problems

Troubleshooting is an essential skill for anyone involved in 3D printing. As this technology becomes more accessible, understanding how to methodically approach and resolve “3D Printing Problems” is crucial. This section provides a structured approach to diagnosing and fixing common issues, ensuring that your 3D printer operates efficiently and your projects turn out as expected.

Calibration for Precise Movements

Proper calibration of your 3D printer is fundamental for achieving high-quality prints. Misalignment or improper calibration can lead to numerous issues such as poor adhesion, inaccurate layering, or even complete print failures.

Steps to Calibrate Your 3D Printer:

- Level the Print Bed: Begin with ensuring your print bed is level. An unlevel bed can cause adhesion problems and affect the quality of the print right from the first layer.

- Adjust Z-Axis: The height of the Z-axis needs precise adjustment to ensure the first layer is neither too squished nor too loose.

- Calibrate Extruder: Calibration of the extruder ensures that the amount of filament fed into the hot end matches the amount the printer expects to extrude.

Adjusting Software Settings

The software that drives your 3D printer plays a significant role in the outcome of your prints. Adjusting settings within your slicing software can resolve a multitude of printing issues.

Key Software Settings to Adjust:

- Print Speed: Slowing down the print speed can improve print quality and give more time for layers to adhere properly.

- Temperature Settings: Adjusting the temperature for both the print bed and the extruder can help with better material flow and layer adhesion.

- Support Settings: For complex prints, adjusting support settings is crucial. More support can prevent the model from collapsing, but too much can make post-processing difficult.

Systematic Problem-Solving Approach

When faced with a 3D printing problem, taking a systematic approach can help isolate and resolve the issue more effectively.

Systematic Troubleshooting Steps:

- Identify the Problem: Clearly define what is wrong with your print. Is it warping, stringing, poor adhesion, or something else?

- Check the Most Likely Causes: Based on the problem, review settings or components that are most likely to cause such an issue.

- Test and Evaluate: Adjust one variable at a time and test to see if the issue resolves. This approach helps pinpoint the exact cause.

- Document Your Fixes: Keep a log of issues and how they were resolved. This can speed up troubleshooting in the future and help in understanding how different settings affect the print quality.

Regular Maintenance Checks

Routine maintenance is key to avoiding many common “3D Printing Problems”. Regularly cleaning and inspecting the printer can preempt many issues that might lead to bigger problems later.

Maintenance Tips:

- Clean the Build Plate: Ensure the build plate is clean and free of any residue or debris before starting a new print.

- Lubricate Moving Parts: Apply lubricant to the printer’s rods and bearings to ensure smooth movement.

- Check for Wear and Tear: Regularly inspect all printer parts for signs of wear. Replace parts that are worn out or damaged to maintain print quality and machine reliability.

6. Maintenance Tips for 3D Printers

Effective maintenance is crucial for any 3D printer’s longevity and performance. Regular upkeep not only prevents a multitude of “3D Printing Problems” but also ensures that each print job runs smoothly, producing consistently high-quality results. Here are detailed guidelines to help you maintain your 3D printer optimally.

Cleaning Your 3D Printer

Keeping your 3D printer clean is fundamental. Dust, filament residues, and other particles can accumulate over time, potentially leading to various printing issues such as clogging and poor print quality.

Steps for Effective Cleaning:

- Clean the Extruder: Regularly wipe down the extruder’s outer surface and use a needle to remove any debris from the nozzle to prevent clogs.

- Remove Debris from Print Bed: After each print, clean the print bed. Use isopropyl alcohol for a deeper clean to remove any sticky residue.

- Dust Off the Printer: Use a soft brush or compressed air to remove dust from the printer’s body and moving parts.

Lubricating Moving Parts

Lubrication is essential to keep the moving parts of your 3D printer operating smoothly. Proper lubrication reduces wear and ensures that the motion is seamless, which is crucial for achieving the best print quality.

Lubrication Tips:

- Select Appropriate Lubricant: Use a light machine oil for metal parts and a dry lubricant like PTFE for plastic parts that come into contact with each other.

- Apply Lubricant Sparingly: Over-lubrication can attract dust and cause gunk buildup. Apply a small amount on the rods and bearings, ensuring not to drip onto other parts of the printer.

Regularly Checking for Wear and Tear

Regular inspections can catch early signs of wear and tear, which could lead to bigger issues if left unattended. This includes checking belts for tension and integrity, examining bearings for smooth motion, and ensuring screws and connectors are tight.

Inspection Checklist:

- Check Belts and Pulleys: Make sure the belts are tight and not frayed. Loose or worn belts can affect print accuracy.

- Inspect Bearings and Rods: Move the print head and bed manually to feel for any roughness or resistance. If movement is not smooth, it may be time to clean or replace the bearings.

- Tighten Loose Screws: Due to the vibrations caused during printing, screws and connectors may loosen over time. Regularly go over the machine to tighten these components.

Updating Software and Firmware

Keeping your software and firmware up to date is another crucial maintenance task. Updates can fix bugs, improve printer functionality, and sometimes even enhance print quality.

Software Maintenance:

- Regular Updates: Check for updates from your printer manufacturer’s website. Install them as recommended.

- Back-up Settings: Before updating, back up your current settings to avoid losing your configurations.

7. When to Seek Professional Help

While many “3D Printing Problems” can be resolved through at-home troubleshooting and maintenance, there are situations where consulting with a professional is the best course of action. Knowing when to seek professional help can save you time and prevent further damage to your printer. Below are guidelines on recognizing the signs that it’s time to reach out for expert assistance.

Signs That You Need Professional Help

Despite your best efforts, some issues might persist or be too complex for you to solve on your own. Here are some indications that it’s time to consult a professional:

Persistent Mechanical Issues

- Recurring Malfunctions: If you’ve repeatedly tried to fix a mechanical issue without success, a deeper underlying problem may exist that requires professional expertise.

- Unusual Noises: Grinding, clunking, or high-pitched noises during printing can indicate serious mechanical failures that need expert diagnosis.

Electrical or Software Complications

- Firmware Updates Failure: If your printer fails to operate correctly after a firmware update or refuses to update at all, professional help can ensure that your printer’s software is correctly installed and functioning.

- Continued Connectivity Issues: Problems with connecting to your computer or network that can’t be resolved through basic troubleshooting steps might require a technician’s help.

How to Seek Professional Help

When deciding to seek professional help, here are a few steps to consider to ensure you find the right support.

Research Qualified Technicians

- Check Credentials: Look for service providers or technicians with specific experience and positive reviews in handling 3D printers.

- OEM Support: Contact the original equipment manufacturer of your printer. Many companies offer technical support services, and some issues might even be covered under warranty.

Utilize Community Knowledge

- Forums and Community Groups: Before opting for professional repairs, consider consulting the vast array of knowledge available in online 3D printing forums and community groups. Often, other users have experienced similar issues and can offer solutions or recommend reliable professionals.

Prepare for the Consultation

- Document the Issue: Prepare a detailed description of the problem, including what troubleshooting steps you have already taken. This information will be invaluable to the technician and can help expedite the repair process.

- Gather Warranty Information: If your printer is still under warranty, gather all necessary documents and contact the supplier for repair services.

8. Enhancing Your 3D Printing Experience

A successful 3D printing journey isn’t just about troubleshooting and maintenance; it’s also about continually improving and enhancing your setup. Whether you’re a hobbyist or a professional, upgrading your printer’s components and experimenting with different printing materials can significantly elevate the quality of your outputs and make the entire process more enjoyable. Here’s how you can tackle these improvements while keeping an eye on potential “3D Printing Problems”.

Upgrading Printer Components

Upgrading various parts of your 3D printer can lead to substantial improvements in print quality, speed, and reliability. Here are some recommended upgrades that can help you mitigate common 3D printing issues:

Consider These Upgrades:

- Extruder: Upgrading to a dual extruder can allow you to use multiple colors or materials in a single print, while upgrading to a more precise extruder can improve the quality and consistency of your prints.

- Print Bed: Switching to a heated bed can help with adhesion issues and reduce warping, especially when printing with materials prone to shrinking.

- Stepper Motors: Higher quality stepper motors can enhance the accuracy of your printer’s movements, reducing issues like layer shifting.

- Cooling Fans: Improved part cooling fans can help in achieving better overhangs and finer details by rapidly cooling the filament as it is deposited.

Experimenting with Different Materials

The choice of filament can greatly impact the final results of your prints. Each material comes with its own set of characteristics and challenges, so experimenting with different types can not only expand your creative options but also improve the functionality of your printed objects.

Types of Materials to Explore:

- PLA (Polylactic Acid): Easy to use and environmentally friendly, PLA is great for beginners.

- ABS (Acrylonitrile Butadiene Styrene): Known for its toughness and heat resistance, ABS is excellent for printing durable parts but requires a heated bed and good ventilation due to fumes.

- PETG (Polyethylene Terephthalate Glycol): Combines the ease of printing seen in PLA with the strength and flexibility of ABS. It’s also water-resistant, making it suitable for outdoor use.

- Specialty Filaments: These include wood fill, metal fill, and conductive filaments, which can be used to create objects with unique finishes and properties.

Best Practices for Material Experimentation:

- Test Settings: Each new material may require different settings, such as temperature and print speed. Small test prints can help determine the optimal settings for each material.

- Storage Solutions: Different materials have different storage requirements to prevent degradation. For instance, nylon should be kept dry and away from moisture to avoid print quality issues.

9. Conclusion

While 3D printing offers immense potential, it comes with its share of challenges. With this guide, you’ll be better equipped to handle common issues and enjoy a smoother 3D printing experience.

10. FAQs

- What is the most common 3D printing problem?

Warping due to temperature issues and poor adhesion. - How often should I maintain my 3D printer?

Regular maintenance is recommended at least once a month. - Can software updates cause printing issues?

Yes, always ensure compatibility and stability before updating. - What are the best materials for a beginner?

PLA is user-friendly and generally easier to work with. - How do I know if a problem is beyond my ability to fix?

If basic troubleshooting doesn’t work, seeking professional advice is the next best step.

Resources

- https://www.archtechus.com/blog/difference-between-oem-tpm-independent-maintenance-support

- https://www.fluorotec.com/materials/ptfe/what-is-ptfe/