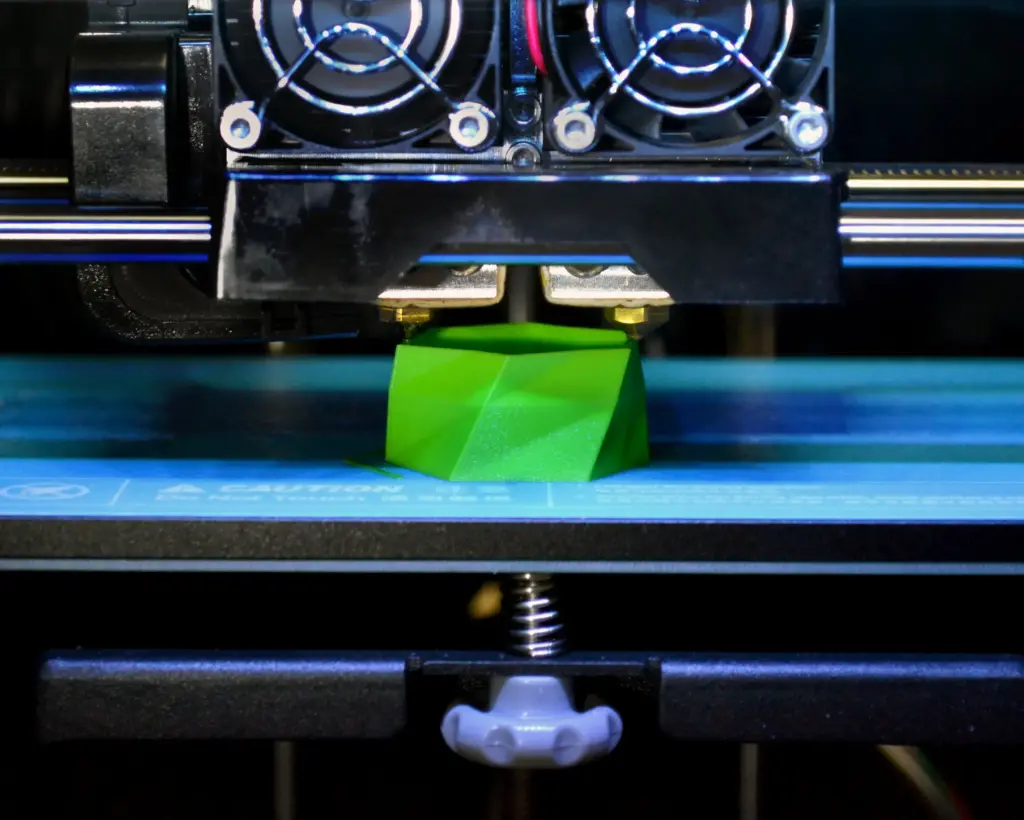

3D Printer Retraction Calibration: The Ultimate Guide to Flawless Prints

When it comes to achieving flawless 3D prints, retraction calibration is a game-changer. If you’ve ever struggled with stringing, blobs, or ooze on your prints, you’re not alone. This guide dives into the nitty-gritty of 3D printer retraction calibration, giving you actionable steps to up your printing game. Let’s get started, shall we?

1. What is Retraction Calibration in 3D Printing?

Understanding Retraction in 3D Printing

Before we jump into calibration, let’s clarify what retraction means. Retraction is when the 3D printer pulls back filament slightly during non-printing moves to prevent unwanted material from oozing out of the nozzle. Sounds simple, right? But without proper calibration, retraction can cause more harm than good.

2. Why is Retraction Calibration Important?

Avoiding Stringing and Blobs

Have you ever noticed tiny threads of plastic between printed parts? That’s stringing, and improper retraction settings are the usual culprit. Calibrating retraction reduces these unsightly strings and ensures clean, professional-looking prints.

Improving Print Quality

Retraction calibration isn’t just about aesthetics. It directly impacts print accuracy and surface smoothness. A well-calibrated printer gives you seamless results, saving time and filament.

3. How to Start Retraction Calibration

Retraction calibration is the foundation of clean and professional-quality 3D prints. Proper calibration helps reduce stringing, blobs, and oozing, ensuring your projects turn out just as you envisioned. Starting this process can seem daunting, but with the right tools and a step-by-step approach, you’ll master it in no time.

Tools You’ll Need

Before diving into the process, gather the necessary tools and materials. Having everything ready ensures a smoother calibration journey.

- 3D Printer with Adjustable Retraction Settings

Ensure your 3D printer allows you to adjust retraction settings such as distance and speed. Most modern printers support these adjustments either through the slicer or the printer’s firmware. - Calibration STL Files

Download free STL files designed for testing stringing and retraction. These files usually feature structures with gaps or towers that make stringing visible, helping you identify issues quickly. - Slicing Software (Cura or PrusaSlicer)

Your slicer plays a critical role in retraction calibration. Tools like Cura and PrusaSlicer allow for precise adjustments to retraction parameters. They also offer visual previews of travel paths to anticipate stringing-prone areas. - Filament (Your Regular Choice)

Use the filament you plan to work with regularly. Retraction settings can vary significantly between filament types, so calibrating with your preferred material ensures consistent results in future prints.

Step-by-Step Retraction Calibration,

To calibrate retraction effectively, follow this systematic process. It allows you to isolate variables and optimize your settings gradually.

Step 1 – Set a Baseline

Start by noting the default retraction settings in your slicer. These settings serve as your starting point and give you a benchmark for adjustments. Key parameters to document include:

- Retraction Distance: This determines how far the filament is pulled back during non-print moves.

- Retraction Speed: This controls how quickly the filament is retracted.

Every printer comes with default settings based on its design (e.g., Bowden vs. direct drive). Record these values to compare improvements as you proceed.

Step 2 – Print a Stringing Test

Load a stringing test STL file into your slicer and print it using your baseline settings. This file typically includes a series of thin columns spaced apart.

- What to Look For: Examine the print for visible strings between the columns.

- Why This Matters: Stringing indicates excessive oozing during travel moves, a problem retraction calibration aims to fix.

This step provides a clear picture of how well your current retraction settings are performing.

Step 3 – Adjust Retraction Distance

The first variable to tweak is the retraction distance. This defines how much filament the extruder retracts during a move.

- How to Adjust: Increase or decrease the distance in small increments, such as 0.5 mm.

- Common Ranges: Bowden printers typically require a retraction distance between 4-7 mm due to their longer filament paths. Direct drive printers, on the other hand, usually need only 1-3 mm.

After making an adjustment, rerun the stringing test. Observe the print to determine if stringing is reduced. Keep iterating until the print shows minimal to no stringing.

Step 4 – Tweak Retraction Speed

Once you’ve optimized the distance, focus on retraction speed. The speed determines how quickly the filament is pulled back and pushed forward again.

- Slow Retraction (20-40 mm/s): Ideal for avoiding filament grinding, especially with softer materials like TPU.

- Fast Retraction (40-70 mm/s): Helps minimize oozing but can cause grinding in some cases.

Adjust the speed in increments of 5-10 mm/s and rerun the stringing test after each change. Look for improvements in stringing while ensuring the filament isn’t grinding or under-extruding.

Step 5 – Balance Temperature

Retraction settings alone might not solve stringing if the nozzle temperature is too high. High temperatures can cause excessive oozing, even with optimal retraction settings.

- How to Adjust: Lower the temperature in small increments (5-10°C) while printing another stringing test.

- Typical Ranges: PLA works well around 190-210°C, while ABS and PETG require higher temperatures.

Balancing the retraction settings with the right temperature ensures the filament solidifies quickly, reducing unwanted oozing.

4. Common Retraction Calibration Issues and Fixes

Even after adjusting retraction settings, issues can still arise. Understanding the symptoms of common problems and their fixes is crucial to fine-tuning your 3D printer retraction calibration. Let’s dive into the three most frequent issues you might encounter.

Too Much Retraction

When retraction settings are too aggressive, the printer pulls back more filament than necessary. This over-correction leads to specific symptoms that can ruin your print.

Symptoms:

- Gaps in the Print: Missing material in layers where the filament didn’t re-prime correctly after retraction.

- Filament Grinding: The extruder gear chews into the filament, leaving it unusable.

Fix:

- Reduce Retraction Distance: Decrease the retraction distance in small increments, such as 0.5 mm, until the gaps disappear.

- Lower Retraction Speed: Slower speeds (e.g., 20-30 mm/s) ensure the filament isn’t pulled back too quickly, preventing grinding.

Experiment with these adjustments and run test prints to find the right balance for your printer and filament type.

Too Little Retraction

Under-calibrated retraction settings lead to inadequate filament pullback during non-print moves. This results in visible flaws that are both frustrating and unattractive.

Symptoms:

- Persistent Stringing: Thin plastic threads appear between print structures.

- Blobs or Oozing: Excess material collects at corners or at the start of a new layer.

Fix:

- Increase Retraction Distance: Start by raising the distance by 0.5 mm increments. Bowden extruders often need more (4-7 mm), while direct drive extruders require less (1-3 mm).

- Increase Retraction Speed: Faster retraction (40-60 mm/s) can prevent oozing while minimizing stringing.

Remember to test each adjustment with a calibration STL file to ensure noticeable improvements.

Filament Grinding

Filament grinding occurs when the extruder gear damages the filament surface, making it harder for the printer to push it through the nozzle. This issue is typically linked to overly aggressive retraction settings.

Cause:

- Retraction speed is set too high, causing the extruder motor to struggle with the abrupt movements.

Solution:

- Reduce Retraction Speed: Lowering the speed to 20-40 mm/s often resolves grinding without impacting print quality.

- Check Filament Tension: Ensure the filament feeder is set to the correct tension. Too tight, and the filament gets damaged; too loose, and it doesn’t feed properly.

This adjustment keeps your extruder functioning smoothly and prolongs the life of your filament.

5. Tips for Mastering Retraction Calibration

Retraction calibration is not just about fixing issues; it’s about preventing them in the first place. Use these expert tips to perfect your calibration process.

Use Calibration Towers

Calibration towers are essential tools for optimizing 3D printer retraction calibration. These towers consist of multiple segments, each printed with varying retraction settings.

Why Calibration Towers Help:

- They allow you to test several retraction distances or speeds in one print.

- You can compare the results visually, making it easier to identify the best settings.

How to Use Them:

- Download a calibration tower STL file from a trusted source.

- Modify the retraction settings for each layer or segment in your slicer.

- Print the tower and analyze each segment for stringing or blobs.

This method saves time and filament while helping you zero in on optimal settings.

Keep Notes

Documenting your calibration process might seem tedious, but it’s invaluable for future prints. Every filament type, printer, and even nozzle size can require unique retraction settings.

How to Track Settings:

- Create a spreadsheet or physical notebook.

- Record key parameters like retraction distance, speed, nozzle temperature, and travel speed.

- Note the filament brand and type (e.g., PLA, PETG, TPU).

Having these notes on hand means you can quickly reference proven settings when switching filaments or starting a new project.

Optimize Other Settings

Retraction settings don’t work in isolation. Other printer parameters significantly impact stringing and overall print quality.

Key Settings to Fine-Tune:

- Travel Speed: Faster travel speeds reduce the time the nozzle has to ooze material. Increase travel speed in small increments (e.g., 5 mm/s) to test the results.

- Layer Height: Thicker layers tend to mask minor imperfections but can also exacerbate stringing. Experiment with smaller layer heights for detailed prints.

- Cooling Settings: Cooling helps solidify the filament faster, preventing unwanted oozing. Ensure your cooling fan is operating at optimal levels for the material being used.

Adjusting these settings alongside retraction calibration creates a more balanced printing process, leading to superior results.

6. When to Recalibrate Retraction?

Calibration isn’t a one-and-done process. There are specific scenarios when recalibrating your 3D printer retraction calibration becomes necessary to maintain high-quality prints. Ignoring these moments can lead to subpar results or wasted filament.

Switching Filaments

Different filament types have distinct properties, which means they interact with your printer in unique ways. This variability makes recalibrating retraction settings crucial when changing materials.

Why Materials Matter:

- PLA: PLA is a rigid and easy-to-use filament. It requires minimal retraction—typically 1-2 mm for direct drive systems or 4-6 mm for Bowden setups.

- TPU: Flexible materials like TPU are prone to stringing and require reduced retraction speed and distance to avoid filament grinding.

- PETG: PETG balances strength and flexibility but tends to ooze more, often needing tighter retraction settings.

- ABS: ABS has a lower viscosity at higher temperatures, making it less likely to string but more prone to blobs if improperly calibrated.

When to Recalibrate:

- Switching between filament types (e.g., PLA to PETG).

- Changing filament brands, even within the same material, as slight composition differences can impact performance.

- Using specialty filaments like carbon fiber or wood-filled, which have unique flow characteristics.

By recalibrating for each filament, you’ll avoid stringing, under-extrusion, or over-extrusion, ensuring consistent results with every material.

Upgrading Hardware

Any hardware modification that impacts the extrusion system can alter the dynamics of your retraction settings. These changes necessitate recalibration to maintain optimal performance.

Common Upgrades That Require Recalibration:

- Nozzle Changes:

- Switching to a larger nozzle increases the flow rate, requiring adjustments to retraction speed and distance.

- Smaller nozzles demand more precise settings to avoid stringing and ensure consistent extrusion.

- Extruder Upgrades:

- Direct drive extruders have shorter filament paths, so they need less retraction than Bowden extruders.

- Upgrading to an all-metal extruder may require recalibration due to improved heat resistance and different filament grip.

- Hotend Replacement:

- A new hotend can have varied heat zones or flow characteristics, affecting filament behavior during travel moves.

Why Recalibration Helps:

Calibrating after a hardware change ensures the printer performs seamlessly with the upgraded components. This step prevents issues like increased oozing, stringing, or under-extrusion, which can arise from unadjusted settings.

7. Advanced Retraction Techniques

Once you’ve mastered the basics of 3D printer retraction calibration, you can explore advanced techniques to refine your prints further. These methods address specific challenges like oozing, blobs, and scratches on the surface of your prints.

Z-Hop

Z-hop, or Z-lift, is a feature that slightly raises the nozzle during travel moves. This technique is particularly helpful for avoiding scratches or defects on your prints.

How Z-Hop Works:

- During travel moves, the nozzle lifts by a small amount (typically 0.1-0.5 mm).

- This lift prevents the nozzle from dragging across the surface of the print, which could cause scratches or dislodge layers.

When to Use Z-Hop:

- Printing models with tall, thin features that the nozzle might collide with during travel moves.

- Working with soft or flexible filaments prone to surface damage.

- Reducing the risk of blobs forming when the nozzle touches freshly extruded layers.

How to Adjust Z-Hop in Your Slicer:

- Navigate to the retraction settings in your slicer.

- Enable Z-hop or Z-lift during retraction.

- Set the lift height based on your printer’s capabilities (start with 0.2 mm as a baseline).

This feature complements retraction settings by further minimizing the chance of unwanted marks or material buildup.

Coasting

Coasting is another advanced feature available in many slicers. It helps counteract oozing at the end of a print move by preemptively stopping extrusion before a travel move.

How Coasting Works:

- The extruder halts filament extrusion slightly before completing a move.

- This method allows the pressure in the nozzle to dissipate, preventing excess material from oozing out.

Benefits of Coasting:

- Reduces blobs at the start and end of layers.

- Improves seam quality for models that require high detail.

- Works well with filaments prone to oozing, such as PETG or TPU.

How to Enable Coasting:

- In your slicer software, locate the coasting settings (commonly under retraction or advanced extrusion settings).

- Enable coasting and specify the volume or length to stop extruding before the end of a move.

- Test with a small value and increase incrementally until blobs are minimized.

When to Use Coasting:

- Printing intricate models where detail is critical.

- Using materials known for excessive oozing, especially at high temperatures.

8. How Retraction Settings Differ by Printer Type

Understanding how retraction settings vary between printer types is essential for effective 3D printer retraction calibration. The type of extruder your printer uses—Bowden or direct drive—significantly influences the retraction distance and speed needed for optimal results.

Bowden vs. Direct Drive

Bowden Extruders

The Bowden extruders feature a long PTFE tube that guides the filament from the extruder motor to the hotend. While this design reduces the weight on the print head, it introduces specific challenges for retraction.

- Longer Retraction Distances:

Due to the extended filament path, Bowden setups require retraction distances of 4-7 mm. The additional length compensates for the “slack” in the system caused by filament elasticity and the movement within the tube. - Moderate Retraction Speeds:

Retraction speeds for Bowden extruders typically range between 30-50 mm/s. Higher speeds can cause filament grinding or create excessive pressure in the tube. - Common Use Case:

Bowden systems are popular in larger or budget printers because they reduce the print head’s weight, allowing for faster travel moves. However, they require more precise calibration to avoid stringing.

Direct Drive Extruders

Direct drive extruders position the motor directly above the hotend, offering better control over filament retraction and extrusion.

- Shorter Retraction Distances:

Direct drive systems usually need retraction distances of 1-3 mm. The shorter filament path eliminates the slack seen in Bowden systems, enabling quicker and more precise retractions. - Faster Retraction Speeds:

Direct drive setups can handle higher retraction speeds of 40-60 mm/s without risking filament grinding, especially for rigid filaments like PLA. - Common Use Case:

These systems excel with flexible filaments like TPU, where tight control over the filament path minimizes the risk of tangling or misfeeding.

9. Testing and Fine-Tuning: A Real-Life Example

Calibrating retraction can feel like solving a puzzle with too many pieces. When I first tackled 3D printer retraction calibration, I was overwhelmed by the sheer number of variables. Filament type, nozzle size, retraction distance, and speed—it all seemed like too much to handle.

The Journey to the Sweet Spot:

- I started with the default slicer settings and printed a stringing test. The results were disappointing: threads of filament stretched between every column.

- Using a calibration tower STL file, I tested various retraction distances in increments of 0.5 mm. After several iterations, I found 5 mm was optimal for my Bowden setup.

- Next, I adjusted retraction speed. Increasing it to 45 mm/s reduced stringing without causing filament grinding.

- Finally, I fine-tuned the nozzle temperature, lowering it by 5°C to prevent excess oozing.

The Result:

After calibrating, my prints transformed. Clean edges, no stringing, and a professional finish made all the trial and error worthwhile. This process taught me the value of patience and systematic testing in achieving optimal print quality.

10. The Role of Slicing Software in Retraction Calibration

Your slicer is the control hub for your 3D printer retraction calibration. Tools like Cura and PrusaSlicer make it easy to customize and fine-tune retraction settings, offering features designed to simplify the calibration process.

Customizing Settings in Cura

Cura is one of the most widely used slicing software options for 3D printing. It provides a user-friendly interface and robust tools to adjust retraction settings.

Key Features in Cura:

- Material Tab:

- The “Material” tab in Cura lets you adjust retraction distance and speed. You can also enable or disable retraction entirely, depending on the print.

- Preview Mode:

- Use Cura’s preview mode to visualize travel moves. This feature highlights areas where retraction will occur, helping you identify potential stringing-prone paths.

- Travel Settings:

- Cura allows you to adjust travel speed and enable Z-hop, which lifts the nozzle during non-print moves to avoid surface scratches.

Tips for Using Cura:

- Start with conservative retraction values, especially if you’re new to calibration.

- Use Cura’s “Experimental” settings to explore advanced features like coasting or gradual retraction adjustments.

- Save profiles for different filaments to streamline future calibrations.

PrusaSlicer’s Calibration Tools

PrusaSlicer stands out for its powerful, built-in calibration tools, making it a favorite among advanced users and beginners alike.

Why PrusaSlicer Excels for Retraction Calibration:

- Calibration G-Codes:

- PrusaSlicer generates G-codes specifically designed for calibration. You can print calibration towers or stringing tests directly, saving time on setup.

- Dynamic Filament Profiles:

- The software includes preconfigured profiles for popular filament types, offering a great starting point for retraction settings.

- Intuitive Interface:

- PrusaSlicer organizes retraction settings into logical categories, such as “Retraction,” “Cooling,” and “Extrusion.” This structure simplifies fine-tuning.

Tips for Using PrusaSlicer:

- Print a retraction calibration tower to test multiple settings in one go.

- Leverage the slicer’s volumetric flow control to adjust settings based on nozzle diameter and filament type.

- Use the live preview to monitor changes to retraction settings and travel paths.

11. Conclusion

Mastering 3D printer retraction calibration is essential for achieving high-quality prints. By understanding retraction mechanics, systematically testing settings, and fine-tuning for your specific printer and filament, you’ll eliminate stringing, blobs, and other print imperfections. With these tips and tricks, you’re well on your way to printing like a pro. Now, go forth and create!

12. FAQs

- What is the ideal retraction distance for PLA?

Most PLA prints well with a retraction distance of 1-3 mm for direct drive extruders and 4-6 mm for Bowden setups. - Why does my printer still string after retraction calibration?

Check your nozzle temperature, travel speed, and filament quality. High temperatures and slow travel speeds often cause stringing. - How often should I recalibrate retraction?

Recalibrate whenever you change filament brands, types, or hardware components like nozzles or extruders. - Can retraction calibration fix all print issues?

No, retraction calibration mainly addresses stringing and oozing. For other issues like warping or layer adhesion, look at temperature and bed leveling. - Is retraction calibration necessary for flexible filaments?

Yes, but use lower retraction speeds and distances to avoid filament grinding or jamming.