3D Print Brim Mastery: Elevate Your Printing Skills with Essential Brim Techniques

Introduction to 3D Printing and Brims

3D printing, an incredible technological innovation, has revolutionized how we create and conceive objects. In my journey as a 3D printing enthusiast, I’ve discovered the importance of mastering not just the printing process but also the preparatory steps. One such critical aspect is the use of a 3D print brim.

What is a 3D Print Brim?

Definition and Basic Concept

A 3D print brim is often the unsung hero of the 3D printing process. Essentially, it is an extra layer or several layers of material that are printed first, encircling and connected to the base of the actual model. Imagine it as a thin, flat border or extension that emanates from the outer edges of your print. This isn’t part of the final product; instead, think of it as a temporary foundation.

- Physical Appearance: It’s akin to the brim of a hat, hence the name. Thin and usually only a few layers thick, it spreads outward from the base of the printed object.

- Material Compatibility: The brim is made from the same material as the object you are printing, ensuring uniformity in heating and adhesion characteristics.

The Role of Brims in 3D Printing

Understanding the role of brims in 3D printing is crucial for anyone delving into this field. Their utility is multifaceted, but their primary goals are to ensure adhesion and reduce warping.

- Increasing Surface Area for Adhesion: By widening the base of your print, the brim increases the surface area that sticks to the build plate. This is particularly beneficial for prints with small footprints. For instance, if you’re printing a narrow, tall structure, a brim can act as an anchor, holding it firmly to the bed.

- Preventing Warping: Warping occurs when parts of the print cool and contract faster than others, causing them to lift off the build plate. This is where the brim comes in. By spreading the stress over a larger area, it reduces the forces that cause lifting and warping. This is vital for materials like ABS, which are prone to significant warping.

- Assisting with Delicate Prints: For models with fine details or fragile parts at the base, a brim can provide the necessary support during the initial stages of printing. It ensures that these delicate parts don’t move or get dislodged.

- Enhancing Print Quality: A well-applied brim can also improve the overall quality of the print. By ensuring a stable base, it helps in achieving a more accurate and defect-free output.

When to Use a 3D Print Brim

Understanding when to utilize a 3D print brim can make a significant difference in the outcome of your printing projects. Brims are not a one-size-fits-all solution; their necessity varies based on the design, material, and complexity of the print.

Identifying the Need for Brims

In the world of 3D printing, knowing when to deploy a brim is as important as knowing how to print. Here are some key scenarios where a brim can be particularly beneficial:

- Small Base Objects: Objects with a small footprint are often vulnerable to detachment from the build plate. A brim increases the surface area, providing more grip and stability.

- Tall and Thin Models: For designs that are tall and slender, the risk of toppling or warping is higher due to less contact with the build plate. A brim acts as a stabilizing anchor.

- Designs with Fine Details: When your model has intricate details, especially at the base, a brim can help in securing these delicate parts during the initial layers of printing.

Material Considerations

Different printing materials exhibit distinct characteristics, influencing the decision to use a brim:

- ABS (Acrylonitrile Butadiene Styrene): Known for its strength and heat resistance, ABS has a propensity to warp due to thermal contraction. A brim is highly recommended to mitigate this.

- PLA (Polylactic Acid): PLA is more forgiving and less prone to warping compared to ABS. While a brim might not be necessary in many cases, it can still be beneficial for intricate designs or unstable structures.

- Other Materials: For materials like PETG, Nylon, or TPU, consider their individual properties. For instance, TPU‘s flexibility might require a brim for better adhesion.

Complexity of the Print

The design of your object plays a pivotal role in deciding the need for a brim:

- Overhangs and Unsupported Edges: Designs that feature significant overhangs or floating parts without support can greatly benefit from the added stability of a brim.

- Geometric Complexity: Models with complex geometries or multiple protruding elements might face challenges in adhesion. In such cases, a brim ensures a successful print by providing a solid base.

- Layer Adhesion Concerns: For prints where the initial layers are crucial and prone to detachment, a brim can be a lifesaver.

How to Implement a Brim in Your 3D Printing

Integrating a brim into your 3D printing process is a straightforward yet nuanced task that can vastly improve the quality of your prints. Whether you’re a seasoned 3D printing enthusiast or a beginner, understanding how to effectively implement a brim is key. Here’s a detailed step-by-step guide to ensure you get it right every time.

Step-by-Step Guide

- Selecting the Brim Option

- Start by opening your slicing software, which converts your 3D model into printable instructions.

- Within the software, navigate to the adhesion settings. Here, you’ll find the option to add a brim.

- Selecting this option is the first step in telling your printer to create a brim during the printing process.

- Adjusting the Width

- The width of the brim is a critical factor to consider. It’s a balancing act between ensuring enough adhesion and ease of removal post-printing.

- A good rule of thumb is to start with a brim width of 5-8 mm. This range usually provides sufficient surface area for adhesion without being overly difficult to remove.

- Remember, the correct width can vary based on the size and design of your print, as well as the material used.

- Printing the Brim

- Once you’ve configured your settings, it’s time to print.

- The printer will first lay down the brim before it begins printing the actual model.

- It’s crucial to monitor the first few layers of printing to ensure the brim is adhering properly to the build plate.

Software Settings and Adjustments

- Different slicing software have their own unique interfaces and settings for brims.

- Spend some time familiarizing yourself with these options in your specific software. This understanding is vital for fine-tuning the brim settings to suit your particular printing needs.

Practical Tips for Perfect Brims

- Level and Clean Print Bed: Before starting your print, ensure that the print bed is perfectly level. An uneven bed can lead to poor adhesion of the brim.

- Clean Surface: Dust, grease, or remnants from previous prints can hinder brim adhesion. Clean the print bed thoroughly for optimal results.

- Nozzle Temperature Adjustments: If the brim isn’t sticking well, it might be due to the temperature of the nozzle. Adjusting the nozzle temperature for the first layer can improve adhesion.

- Speed Adjustments: Slowing down the print speed for the first few layers can also help in achieving a better brim.

- Regular Calibration: Regularly calibrating your printer ensures consistent print quality, which is especially important for effective brim adhesion.

Incorporating a brim into your 3D printing routine can seem like an additional step, but its benefits in enhancing print quality and success are immense. By following these guidelines and adjusting based on your specific printer and model, you’ll be able to master the art of using brims effectively.

Advantages of Using a Brim, Challenges, and Expert Advice

Advantages of Using a Brim in 3D Printing

Integrating a brim into your 3D printing process brings a host of benefits, enhancing not just the print’s success rate but also its overall quality. Here’s a detailed look at the advantages of using a brim:

Improved Adhesion

- Enhanced Stability: The brim creates a larger footprint on the build plate, which significantly increases the stability of the print, especially in the crucial early stages.

- Uniform Heat Distribution: A brim helps in maintaining a more consistent temperature at the base of the print, which is critical for materials sensitive to temperature variations.

Reduced Warping

- Critical for Certain Materials: Materials like ABS, which are prone to warping due to thermal contraction, greatly benefit from the added stability provided by a brim.

- Prevents Print Failures: By mitigating warping, brims can prevent print failures, which is particularly important for long or complex print jobs.

Challenges and Solutions

While brims are incredibly beneficial, they also come with their own set of challenges, primarily related to their removal and the potential impact on the final print.

Removal of the Brim Post-Printing

- Careful Removal: Use a sharp craft knife or a spatula to gently pry the brim away from the print. It’s important to be patient and careful to avoid leaving marks or damaging the print.

- Sanding and Finishing: In some cases, you might need to sand the edges of your print post-brim removal for a smooth finish.

Avoiding Common Mistakes

- Level Print Bed: A well-leveled bed is crucial for a successful brim. An unleveled bed can lead to uneven brim adhesion, making it harder to remove.

- First Layer Calibration: Ensuring the first layer is not too compressed against the bed is key. A too-tight first layer makes brim removal difficult and can affect print quality.

Expert Advice and Best Practices

Drawing from the wealth of knowledge within the 3D printing community, here are some expert tips and best practices for using brims effectively.

Tips from Experienced Printers

- Material-Specific Settings: Adjust brim settings based on the material. For instance, ABS might need a wider brim compared to PLA.

- Trial and Error: Experiment with different brim widths and settings to find what works best for your specific printer and model.

Advanced Techniques and Innovations

- Exploring Alternatives: The 3D printing community is constantly exploring new adhesion methods, such as using adhesion promoters or heated beds, which could someday offer alternatives to brims.

- Flexible Build Plates: The use of flexible build plates is gaining popularity. They allow for easy removal of prints (and brims) by bending the plate, reducing the need for tools.

When Not to Use a Brim in 3D Printing

While brims are a valuable tool in many 3D printing scenarios, there are situations where using a 3d print brim is not necessary or even counterproductive. Understanding when to forego a brim can save time and materials, and also ensure the best possible quality of your 3D prints.

Large Base Objects

- Stable Adhesion: Objects with a large base area have sufficient contact with the build plate, providing stable adhesion without the need for additional support.

- Reduced Warping Risk: Larger footprint objects inherently have less risk of warping, as the weight and distribution of the print are more evenly spread across the build plate.

Use of Rafts or Skirts

- Alternative Adhesion Methods: In some cases, using a raft (a thicker, removable base) or a skirt (a thin outline around the object) might be more suitable for the print’s needs.

- Material Efficiency: Choosing a skirt over a brim, for example, can save material if adhesion is not a major concern.

Simple Geometries and Reliable Materials

- Non-complex Designs: Simple geometric shapes with ample contact with the build plate often do not require the extra adhesion that a brim provides.

- Stable Materials: Materials like PLA, which are less prone to warping, might not require the additional stability that a brim offers.

Print Bed Quality and Printer Calibration

- High-Quality Print Beds: Printers equipped with high-quality or heated print beds can often maintain good adhesion without the need for a brim.

- Proper Calibration: Well-calibrated printers that lay down the first layer evenly and consistently may not require a brim for additional adhesion.

Considerations for Post-Processing

- Surface Finish: In cases where the aesthetic quality of the base of the print is critical, avoiding a brim can reduce the post-processing work needed to achieve a smooth finish.

- Time Efficiency: Removing a brim requires extra time and effort in post-processing. If the print can adhere well without a brim, it’s often more efficient to print without one.

Slice Settings to Use a Brim in Popular Slicing Software

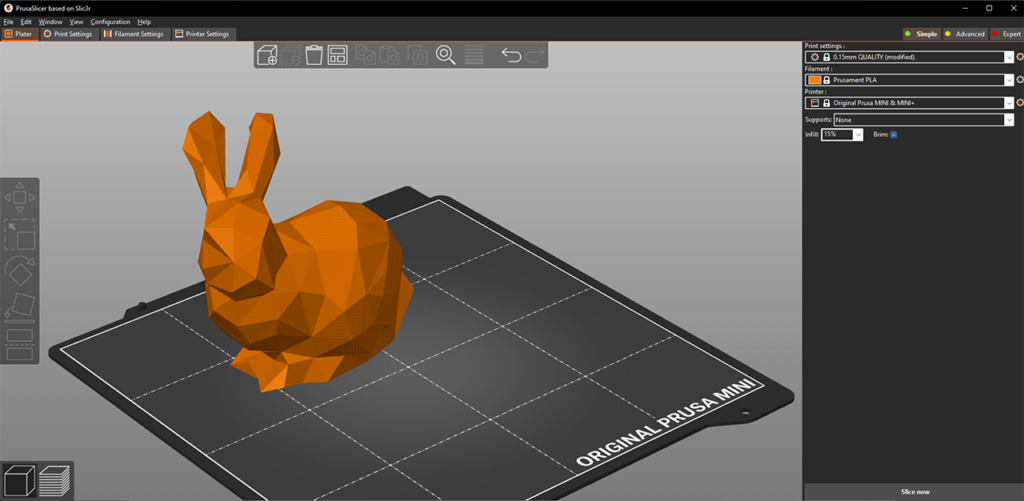

Incorporating a 3d print brim into your 3D printing projects involves adjusting settings in your slicing software. Each software, such as Cura, Simplify3D, and PrusaSlicer, has its own way of handling these settings. Understanding how to configure them correctly is essential for achieving optimal print quality.

Cura

- Accessing Brim Settings: In Cura, you can find brim settings under the ‘Build Plate Adhesion’ section.

- Brim Width: Adjust the width of the brim by specifying the number of lines or millimeters. A standard starting point is 8mm or about 10 lines.

- Brim Line Count: This setting allows you to choose how many lines of brim you want. More lines mean more adhesion but also more material usage.

- Gap Between Brim and Object: Adjusting this setting can help with easier brim removal. A slight gap can make post-processing simpler.

Simplify3D

- Locating Brim Options: In Simplify3D, brim settings are found under the ‘Additions’ tab.

- Adjustable Parameters: You can set the brim’s distance from the object and its size. The software offers detailed control over the brim’s dimensions.

- Brim and Raft Combination: Unlike some other software, Simplify3D allows you to use a brim in conjunction with a raft, offering enhanced adhesion for challenging prints.

PrusaSlicer

- Brim Settings Access: PrusaSlicer has brim settings under the ‘Print Settings’ tab.

- Brim Width Customization: You can customize the width of the brim in millimeters, providing flexibility depending on your print’s requirements.

- Special Features: PrusaSlicer offers unique brim options like ‘Brim ears’, which can be used to add small brims at specific points of the object where extra adhesion is needed.

General Tips for All Slicers

- Material Consideration: Adjust brim settings based on the material you’re using. ABS might need a wider brim compared to PLA due to its tendency to warp.

- Model Geometry: Consider the geometry of your model. A model with a smaller base or intricate details at the bottom will benefit from a wider brim.

- Trial and Error: Experiment with different settings to find what works best for your printer and model. Sometimes, the optimal settings can be found through a process of trial and error.

Real-World Applications, Future Trends, Conclusion, and FAQs

Real-World Applications and Examples

The practicality of a 3D print brim extends far beyond theoretical advantages, finding essential roles in various real-world applications. Here’s an exploration of how brims are making a significant impact in the field of 3D printing:

Case Studies: Precision in Mechanical Parts

- Enhanced Accuracy: In the printing of mechanical components where precision is paramount, brims have played a crucial role in ensuring dimensional accuracy.

- Preventing Deformation: For parts that need to fit together or function in mechanical systems, the stability provided by brims prevents warping, which can otherwise lead to misfitting components.

Comparative Analysis with Raft and Skirt

- Rafts: These are much thicker than brims and create a complete thick layer under the entire print. While they provide excellent adhesion and stability, they are material-intensive and can be challenging to remove.

- Skirts: Skirts, circling around the object without touching it, are primarily used for priming the nozzle and ensuring a consistent flow of filament. They do not contribute to adhesion.

- Brims – The Middle Ground: Brims offer a balanced solution. They provide better adhesion than skirts without the material excess of rafts, making them ideal for a wide range of prints.

Future of Brims in 3D Printing

The field of 3D printing is rapidly evolving, and with it, the use and technology behind brims are also advancing.

Emerging Trends and Technologies

- Material Innovations: New filament types and enhanced printer capabilities may reduce the need for additional adhesion methods like brims.

- Advanced Printer Bed Surfaces: Developments in bed materials and coatings are improving natural adhesion, potentially making brims less necessary.

- Software Advancements: Improved slicing algorithms and smarter software can optimize adhesion strategies based on the model’s geometry and material.

Conclusion

As we’ve explored, 3D print brims are more than just an add-on; they are a strategic tool in the 3D printing arsenal. Whether you’re printing intricate models or dealing with challenging materials, a well-implemented brim can make all the difference. Remember, the key is to understand when and how to use them effectively.

FAQs

- When should I not use a brim in 3D printing?

If your object has a large base or is printed with materials less prone to warping, like PLA, you might not need a brim. - Can brims be used with any 3D printer?

Yes, brims are a universal feature and can be used with almost any FDM 3D printer. - How do I decide the width of the brim?

It depends on your object’s size and the material. Start with a standard width of 5-8 mm and adjust based on your experiences. - Are there alternatives to using a brim?

Yes, alternatives include rafts, skirts, or adhesion-enhancing substances like glue or hairspray. - Can brims affect the final quality of the print?

If not removed carefully, brims can leave slight marks. However, with proper technique, this can be minimized.

Resources

- https://www.simplify3d.com/

- https://www.prusa3d.com/page/prusaslicer_424/

- https://ultimaker.com/software/ultimaker-cura/