3D Printer Supplies: Your Essential Guide

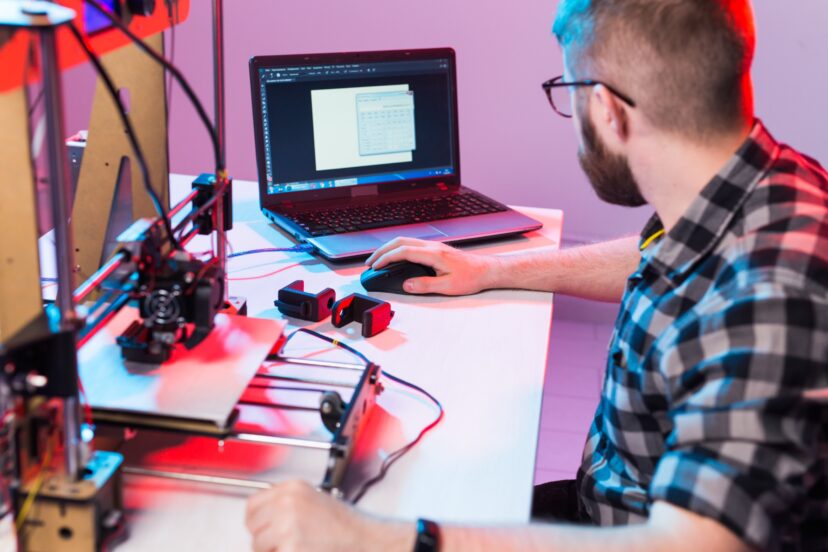

Hey fellow 3D printing enthusiast! Ever felt overwhelmed by the plethora of 3D printer supplies available in the market? Worry no more. Let’s navigate this together!

1. Understanding Your 3D Printer

When delving into the realm of 3D printing, having a comprehensive understanding of your 3D printer is crucial. This knowledge not only enhances your printing experience but also ensures that you make informed decisions when selecting 3d printer supplies. Let’s explore the various components of a 3D printer and how they influence your choice of supplies.

Key Components of a 3D Printer

- Print Bed: This is the surface on which your 3D models are built. Understanding its properties is vital for selecting the right adhesives or bed surfaces, like glass or PEI sheets, to ensure good first-layer adhesion.

- Extruder and Hotend: The heart of your printer, this is where the filament is melted and extruded. The type of extruder and hotend can affect the kinds of filament you can use, especially with materials requiring higher temperatures.

- Filament Feeder System: This system feeds the filament into the hotend. It’s important to consider the feeder mechanism (direct drive or Bowden) as it influences the filament types you can use effectively, like flexible filaments in direct drive systems.

- Control Board and Firmware: The brain of your printer, governing its operation. Knowing its capabilities helps in choosing compatible upgrades like silent stepper drivers or advanced firmware for better print quality and control.

- Power Supply: Essential for ensuring stable operation. The power supply’s capacity can limit the speed at which you can heat the bed and hotend, impacting how quickly you can start printing.

- Stepper Motors and Belts: These components move the printer’s head and build platform. Their quality and condition can affect print precision and, thus, the necessity for maintenance supplies like lubricants or replacement belts.

Factors Influencing Supply Choices

- Printer Capabilities: Different printers have varying capabilities in terms of print size, speed, and material compatibility. This directly impacts the type of filaments and bed adhesives you’ll need.

- Material Requirements: Depending on what you’re printing, different materials like PLA, ABS, PETG, or TPU might be needed, each with their unique properties and requirements.

- Maintenance Needs: Regular maintenance is key to optimal printer performance. Supplies like lubricants, spare nozzles, and cleaning tools become essential.

- Upgrade Potential: Understanding your printer’s upgrade potential can guide you in selecting 3d printer supplies for enhancements, like a more versatile hotend or a better quality print bed.

2. Filaments: The Heart of 3D Printing

When it comes to 3D printing, the choice of filament is crucial. It can mean the difference between a successful, vibrant print and a warped, unusable object. Filaments are the raw materials that your 3D printer transforms into physical objects, and each type comes with its own set of properties and optimal use cases. Let’s dive into the world of filaments and understand how to select the perfect match for your projects.

Understanding Different Types of Filaments

- PLA (Polylactic Acid)

- Origin and Properties: PLA is a biodegradable thermoplastic derived from renewable resources like cornstarch and sugarcane. It’s known for being environmentally friendly and relatively easy to print with.

- Printing Ease: PLA does not require a heated print bed, making it ideal for beginners and those with basic printers.

- Applications and Suggestions: Perfect for decorative items, prototypes, and non-functional parts. Newcomers to 3D printing should start with PLA due to its wide color range and forgiving nature.

- ABS (Acrylonitrile Butadiene Styrene)

- Properties: A strong, durable thermoplastic, ABS is known for its toughness and heat resistance.

- Printing Requirements: ABS requires a heated bed and a well-ventilated space due to its tendency to emit fumes during printing.

- Applications and Suggestions: Ideal for functional parts requiring durability like small household tools, automotive components, and toys. It’s a great choice for more experienced users seeking sturdy prints.

- PETG (Polyethylene Terephthalate Glycol)

- Characteristics: PETG is a hybrid filament that combines the ease of printing seen in PLA with the strength and durability of ABS. It is also resistant to moisture and chemicals.

- Versatility: Offers a good balance between ease of use and functional strength.

- Applications and Suggestions: Opt for PETG when you need a glossy finish or parts that strike a balance between functionality and ease of printing. It’s perfect for intermediate projects.

- Specialty Filaments

- Variety: The market offers a wide range of specialty filaments, from flexible TPU (Thermoplastic Polyurethane) to materials infused with wood, metal, or carbon fiber.

- Unique Properties: These filaments can provide unique textures, finishes, and mechanical properties not achievable with standard filaments.

- Applications and Suggestions: Ideal for advanced users looking to experiment and create specialized items. Each specialty filament presents unique challenges and rewards, perfect for expanding your 3D printing skills.

Key Takeaways for Selecting Filaments

- Match the Filament to the Project: Consider the functional and aesthetic requirements of your project when choosing a filament.

- Printer Compatibility: Ensure your printer can handle the chosen filament, especially regarding temperature requirements and bed adhesion.

- Environmental Factors: Consider the printing environment, especially when using materials like ABS that require ventilation.

- Experiment and Learn: Don’t be afraid to experiment with different filaments as you gain experience. Each material can open new possibilities in 3D printing.

3. Printer Beds and Surfaces: Foundation for Successful 3D Printing

In the world of 3D printing, the importance of the right printer bed and surface cannot be overstated. It is the foundation upon which your creations take shape. The choice of bed and surface directly impacts the adhesion, quality, and ease of print removal. Different materials and project requirements call for different bed surfaces, such as heated beds, glass, PEI sheets, or magnetic mats. Let’s delve deeper into these options to understand their benefits and ideal uses.

Types of Printer Beds and Surfaces

- Glass Beds

- Properties: Glass beds are known for their rigidity and smooth surface. They are highly resistant to scratches and warping.

- Finish Quality: Offers a mirror-like smooth finish to the bottom of prints, enhancing their aesthetic appeal.

- Heat Distribution: Excellent at distributing heat evenly, crucial for materials prone to warping.

- Suggestions: Ideal for those seeking a high-quality finish, especially when printing with PLA or PETG. Use a glass bed for models where the bottom layer’s appearance is paramount.

- PEI (Polyetherimide) Sheets

- Adhesion Characteristics: PEI sheets provide strong adhesion when heated, ensuring prints stay in place during the printing process. They also release easily once cooled.

- Durability: These sheets are durable and can be used repeatedly for multiple prints.

- Ease of Use: Eliminates the need for additional adhesives or tapes.

- Suggestions: A go-to choice for a hassle-free printing experience, especially with materials like ABS and TPU. PEI sheets are perfect for those who frequently print and require easy removal of finished prints.

- Magnetic Mats

- Flexibility: Composed of a flexible material with a magnetic base, these mats can be easily removed and flexed to pop off prints.

- Convenience: Provides a quick and convenient way to remove prints without needing scrapers or additional tools.

- Versatility: Suitable for a wide range of filaments.

- Suggestions: Magnetic mats are a boon for those prioritizing ease of use and rapid turnaround. They are particularly useful in a fast-paced printing environment or for those who print frequently.

Selecting the Right Bed Surface

- Match Surface to Material: Consider the filament type you’re using. For example, ABS works well with PEI, while PLA and PETG are great on glass beds.

- Consider Print Removal: If print removal has been a challenge, opt for PEI sheets or magnetic mats.

- Think About Durability: For a long-lasting option that withstands repeated use, glass and PEI sheets are excellent choices.

- Evaluate Heat Requirements: Ensure that your bed surface is compatible with the heated bed requirements of your printer and material.

4. Nozzles and Extruders: Precision Components in 3D Printing

In the intricate world of 3D printing, nozzles and extruders play a pivotal role in determining the quality and precision of your prints. Often overlooked, these components are essential in translating your digital design into a tangible object. Understanding the different types of nozzles and extruders, and their respective advantages, can significantly enhance your printing experience.

Nozzles: Choosing the Right Material

- Brass Nozzles

- Common Use: Brass nozzles are the standard in many 3D printers, primarily due to their good thermal conductivity.

- Best For: Ideal for basic filaments like PLA and ABS.

- Limitations: They tend to wear out faster when used with abrasive materials like carbon fiber-infused or glow-in-the-dark filaments.

- Suggestions: Keep brass nozzles on hand for general printing but be prepared to replace them more frequently if you’re experimenting with abrasive materials.

- Hardened Steel Nozzles

- Durability: These nozzles are much more durable than their brass counterparts and can withstand the wear from abrasive materials.

- Best For: Excellent for printing with filaments infused with wood, metal, or carbon fiber.

- Considerations: They have lower thermal conductivity than brass, which might require slight adjustments in printing temperatures.

- Suggestions: Invest in hardened steel nozzles if you frequently use abrasive filaments. They offer longevity and maintain precision over time.

Extruders: Direct Drive vs. Bowden

- Direct Drive Extruders

- Positioning: Situated directly above the hotend, this setup provides a short path for the filament.

- Advantages: Allows for more precise control of filament feeding, which is especially beneficial for printing with flexible materials like TPU.

- Considerations: They can make the print head heavier, which might slightly impact printing speed and precision on some printers.

- Suggestions: If you frequently use flexible or tricky filaments, a direct drive extruder is advisable for its superior control and feeding accuracy.

- Bowden Extruder

- Design: In this setup, the extruder is positioned away from the hotend, connected by a PTFE tube.

- Advantages: Results in a lighter print head, potentially allowing for higher printing speeds and less mechanical wear.

- Limitations: The longer path from the extruder to the hotend can cause issues with flexible filaments, leading to jams or inconsistent extrusion.

- Suggestions: Ideal for prints where speed and weight are considerations. However, if you plan on printing with flexible materials, a Bowden setup may not be the best choice.

Tips for Optimal Use

- Regular Maintenance: Regularly check and clean your nozzles to avoid clogs and ensure consistent print quality.

- Nozzle Swapping: Learn to swap nozzles for different projects. A smaller nozzle diameter is great for detail, while a larger diameter can speed up print times for larger objects.

- Understanding Your Needs: Assess the types of projects you undertake most often and choose the nozzle and extruder type that aligns with those needs.

5. Adhesives and Coatings: Ensuring Strong Bed Adhesion in 3D Printing

In the sphere of 3D printing, print detachment or warping is a frequent challenge, particularly in extended printing tasks. A key part of your 3D printer supplies is the strategic use of adhesives and coatings. These crucial products guarantee strong adhesion of your print to the bed during the printing process while ensuring easy removal after completion. Let’s delve into the range of adhesives and coatings available, including everyday options like glue sticks and hairspray, as well as specialized print surface treatments, to elevate your experience with 3D printer supplies.

Commonly Used Adhesives

- Glue Sticks

- Ease of Use: Glue sticks are a simple and accessible solution, particularly effective for prints using PLA filament.

- Adhesion: They provide a reliable adhesion layer between the print and the bed.

- Removal: Prints can be easily removed, and the residual glue is water-soluble, simplifying cleanup.

- Suggestions: Opt for water-soluble glue sticks for convenience. Apply a thin layer on the print bed where the first layer of your print will be.

- Hairspray

- Versatility: A great alternative to glue sticks, hairspray can be used on various bed surfaces, including glass.

- Adhesion Strength: Provides a strong adhesion, minimizing the risks of prints detaching.

- Application: Easy to apply, with a quick spray covering the necessary print area.

- Suggestions: Choose an unscented, extra-hold hairspray for best results. Apply a light coat; over-application can lead to a gunky build-up.

Specialty Print Surface Treatments

- Commercial Solutions (e.g., Outus, Layerneer)

- Formulated for 3D Printing: These products are specifically designed to address adhesion challenges in 3D printing.

- Strong Adhesion: They offer robust adhesion, reducing the likelihood of print failures.

- Ease of Removal: Engineered to release the print easily once the bed cools down.

- Cost vs. Benefit: While pricier than traditional adhesives, their effectiveness, especially for larger or more complex prints, often justifies the cost.

- Suggestions: If you’re dealing with large prints or materials prone to warping, consider investing in these specialty products for consistent results.

Tips for Using Adhesives and Coatings

- Test for Compatibility: Not all adhesives work equally well with every filament type or print bed surface. It’s important to experiment to find the best match.

- Apply Sparingly: Over-application can lead to residue build-up on the print and the bed, making cleanup more challenging.

- Regular Bed Cleaning: Regularly clean your print bed to remove any residual adhesive, ensuring a clean surface for each print.

- Ventilation: When using aerosol-based products like hairspray, ensure proper ventilation to avoid inhaling fumes.

6. Cleaning and Maintenance Supplies: Prolonging the Life of Your 3D Printer

Regular maintenance and cleaning are essential for keeping your 3D printer in top condition, ensuring consistent print quality, and extending its lifespan. Neglecting this aspect can lead to poor print quality, more frequent clogs, and even hardware failures. Let’s delve into the must-have 3d printer supplies for cleaning and maintenance, each playing a critical role in the upkeep of your printer.

Essential Cleaning and Maintenance Tools

- Isopropyl Alcohol (IPA)

- Usage: Primarily used for cleaning the print bed.

- Effectiveness: IPA is excellent at removing grease, oils, and other residues, ensuring your print adheres properly to the bed.

- Concentration: A 90% or higher concentration of IPA is recommended for effective cleaning.

- Storage Suggestions: Store IPA in a cool, dark place and ensure the cap is tightly sealed to prevent evaporation.

- Safety Tip: Use in a well-ventilated area and avoid contact with skin and eyes.

- Lubricants

- Purpose: Keep moving parts like rods, bearings, and lead screws operating smoothly.

- Type of Lubricant: PTFE-based lubricants are often recommended as they are designed specifically for the high-precision requirements of 3D printers.

- Application Tips: Apply lubricant sparingly and regularly, focusing on areas with noticeable friction or noise.

- Brushes and Dental Tools

- Use Cases: Ideal for cleaning out clogged nozzles, removing small bits of leftover filament, and reaching tight spaces within the printer.

- Variety: Having a set of brushes of various sizes is beneficial. Dental tools can be especially handy for detailed cleaning.

- Maintenance Routine: Regularly inspect and clean the nozzle and extruder assembly to prevent clogs and ensure consistent extrusion.

- Cleaning Filament

- Function: Used to clean the interior of the extruder and nozzle by removing residual filament material.

- When to Use: Particularly useful when switching between different types of filaments or colors.

- Usage Suggestions: Run the cleaning filament through the printer periodically, especially after using abrasive or high-temperature materials, to maintain a clean extrusion path.

Best Practices for Maintenance

- Regular Check-Ups: Schedule regular maintenance sessions to check all components of your printer.

- Keep It Clean: Regularly wipe down your printer to prevent dust accumulation, which can affect print quality and mechanical movement.

- Listen and Observe: Pay attention to any unusual noises or changes in print quality, as these can be early signs of maintenance needs.

- Record Keeping: Keep a log of maintenance activities to track the health of your printer over time.

7. Calibration Tools: Achieving Precision in 3D Printing

Accurate calibration is a key element in the world of 3D printing, marking the difference between imperfect prints and flawless ones. Including calibration tools such as digital calipers, bed leveling kits, and thermal monitoring devices in your 3D printer supplies is essential for fine-tuning your printer to achieve precision and consistency. Being adept in utilizing these tools from your 3D printer supplies can significantly enhance the quality of your prints, ensuring that your printer functions optimally.

Essential Calibration Tools for 3D Printing

- Digital Calipers

- Purpose: Used to measure the dimensions of printed parts with high accuracy.

- Precision: Digital calipers provide precise measurements, essential for verifying that your prints match your design specifications.

- Usage Suggestions: Opt for calipers with a digital readout for ease of use and accuracy. Regularly calibrate and check the calibration of your calipers to maintain their precision.

- Application: Measure filament diameter, model dimensions, and parts of the printer itself for replacement or upgrades.

- Bed Leveling Kit

- Importance: A properly leveled bed is fundamental for good print adhesion and layer consistency.

- Components: Typically includes tools like feeler gauges or specific leveling sensors.

- Suggestions: Choose a high-quality leveling kit and take your time during the leveling process. A well-leveled bed will significantly reduce print issues such as warping and poor adhesion.

- Regular Checks: Periodically check and adjust the bed level, especially after moving the printer or completing a large number of prints.

- Thermometers and Thermal Cameras

- Functionality: Used for monitoring and calibrating the temperature of the hotend and print bed.

- Benefits: Accurate temperature readings are crucial for printing with different materials, each requiring specific heat settings.

- Usage Suggestions: These tools are particularly useful when setting up a new printer, troubleshooting print quality issues, or after making hardware modifications.

- Advanced Calibration: Thermal cameras can provide a visual representation of heat distribution across the print bed, helping in fine-tuning the bed heating.

Best Practices for Calibration

- Regular Calibration: Make calibration a regular part of your maintenance routine to ensure consistent print quality.

- Record Keeping: Keep a log of calibration settings and adjustments. This record can be invaluable for troubleshooting and repeating successful prints.

- Understand Material Requirements: Different materials may require different calibration settings, especially in terms of temperature and feed rate.

- Stay Informed: Stay updated with the latest calibration techniques and tools. The 3D printing community is a great resource for tips and advice.

8. Safety Equipment: Prioritizing Safety in 3D Printing

In the realm of 3D printing, where creativity and innovation are frequently emphasized, the significance of safety in managing 3D printer supplies is paramount. Protecting oneself from the potential risks inherent in 3D printing processes is essential, and this includes incorporating safety equipment into your 3D printer supplies. Equipping yourself with the appropriate safety gear, such as respirators and protective eyewear, is just as vital as selecting the correct printing materials. Let’s delve into the critical safety components that should be included in every 3D printing enthusiast’s collection of 3D printer supplies.

Essential Safety Equipment for 3D Printing

- Respirators or Masks

- Purpose: To protect against inhaling potentially harmful fumes, especially when printing with materials like ABS.

- Types: Use a respirator or a mask with a filtration system designed to filter out small particulates.

- Usage Tips: Ensure the mask fits snugly and replace filters as recommended by the manufacturer.

- Protective Eyewear

- Importance: To safeguard your eyes from particles or splashes, particularly when working with heated materials or performing maintenance.

- Specifications: Choose safety glasses or goggles that offer side protection and are made of impact-resistant material.

- Regular Use: Make it a habit to wear protective eyewear whenever you are operating or maintaining your 3D printer.

- Gloves

- Function: To protect your hands from burns when handling hot components and from chemicals when cleaning or applying adhesives.

- Material Considerations: Heat-resistant gloves are recommended for handling hot parts, while nitrile or latex gloves are suitable for chemical handling.

- Best Practices: Always wear gloves when dealing with heated print beds, extruders, or when using solvents and adhesives.

- Fire Extinguisher

- Why It’s Necessary: In rare cases, 3D printers can pose a fire risk, especially if left unattended for long periods or if modifications are improperly made.

- Recommendation: Keep a fire extinguisher nearby, preferably a Class C extinguisher that’s suitable for electrical fires.

- Ventilation

- Significance: Proper ventilation is crucial to ensure that any emitted fumes are adequately dissipated, particularly important in enclosed spaces.

- Solutions: Use your printer in a well-ventilated area. Consider installing an exhaust system or using a printer enclosure with a ventilation fan.

Safety Precautions and Best Practices

- Read and Follow Manufacturer Guidelines: Always read the safety instructions provided by your 3D printer and filament manufacturers.

- Regular Printer Checks: Perform regular checks on your printer’s electrical and mechanical components to ensure they are in good condition.

- Stay Informed: Keep yourself updated on safety practices within the 3D printing community.

- Educate Others: If you share your workspace with others, ensure that they are also aware of and adhere to safety practices.

9. Upgrades and Add-ons: Enhancing Your 3D Printing Experience

Upgrading your 3D printer with various add-ons can transform your printing experience, allowing for greater precision, versatility, and convenience. Whether you’re considering adding a dual extruder, implementing silent stepper motor drivers, upgrading your hotend, or automating bed leveling, these enhancements can significantly improve the functionality and performance of your printer. Let’s delve into some popular upgrades and add-ons, discussing their benefits and considerations.

Popular 3D Printer Upgrades and Add-ons

- Silent Stepper Motor Drivers

- Purpose: To reduce the operational noise of your 3D printer.

- Benefits: Ideal for those who use their printer in a shared space or require a quiet working environment.

- Suggestions: When choosing silent stepper motor drivers, ensure compatibility with your printer’s control board and firmware.

- Installation: Some technical knowledge may be required for installation, so consider professional assistance if you’re not comfortable with DIY electronics.

- Upgraded Hotends

- Enhanced Performance: A high-quality hotend can improve print quality and reliability.

- Material Compatibility: Upgraded hotends can often handle higher temperatures, making them suitable for printing with a wider range of materials like nylon or polycarbonate.

- Suggestions: Research hotends that are compatible with your printer model and consider your most commonly used filament types when selecting an upgrade.

- Auto Bed-Leveling Sensors

- Function: These sensors automate the bed leveling process, ensuring consistent first-layer adhesion.

- Advantages: Greatly reduces the time and effort involved in manual bed leveling, particularly beneficial for large print beds.

- Investment Worth: While adding an auto bed-leveling sensor can be a significant investment, it can be invaluable for those who find manual leveling tedious or challenging.

- Compatibility: Ensure the sensor is compatible with your printer’s firmware and consider the installation process.

Considerations When Upgrading

- Printer Compatibility: Always check that the upgrade or add-on is compatible with your specific printer model.

- Skill Level: Assess your technical skills before undertaking an upgrade. Some upgrades may require advanced knowledge in 3D printer mechanics and electronics.

- Cost vs. Benefit: Evaluate the cost of the upgrade against the benefits it will bring to your 3D printing experience.

- Community Support: Look into the 3D printing community for advice and support. Many users share their experiences with different upgrades, offering valuable insights.

10. Storage Solutions: Preserving the Quality of Your 3D Printing Supplies

Proper storage solutions for 3D printer supplies, particularly for filaments and tools, are essential to maintain their quality and prolong their usability. Moisture, dust, and improper handling can significantly impact the performance of your filaments and the overall organization of your workspace. Implementing effective storage solutions like filament storage boxes, tool organizers, and spool holders can make a substantial difference. Let’s explore these storage options in more detail.

Essential Storage Solutions for 3D Printing

- Filament Storage Boxes

- Purpose: To protect filament from moisture and dust, which can compromise print quality.

- Features: Many storage boxes come with built-in desiccants, such as silica gel packs, to absorb moisture.

- Suggestions: In humid environments, consider filament storage boxes with strong seals and desiccant compartments. Recharge or replace desiccants regularly to maintain effectiveness.

- Additional Tips: Store filaments in a cool, dry place, away from direct sunlight to prevent degradation.

- Tool Organizers

- Function: To keep all your 3D printing tools, such as wrenches, tweezers, and cleaning 3d printer supplies, organized and easily accessible.

- Design: Opt for organizers with multiple compartments or drawers to categorize your tools effectively.

- Benefits: An organized workspace not only saves time but also prevents loss and damage to tools.

- Suggestions: Choose a tool organizer that fits your workspace and accommodates the variety and size of tools you have.

- Spool Holders

- Usage: Facilitate the smooth unwinding of filament, minimizing the risk of tangles and breaks during printing.

- Design Considerations: Adjustable spool holders are versatile, accommodating various sizes of filament spools.

- Placement: Ensure the spool holder is positioned to allow for free movement of the filament to the extruder without inducing stress or tangling.

- Recommendations: If you have multiple printers or use different types of filaments simultaneously, consider having multiple spool holders for convenience.

Best Practices for Storage and Maintenance

- Monitor Filament Condition: Regularly check your filament for signs of moisture absorption, such as brittleness or poor print quality.

- Organize Regularly: Take time to reorganize and clean your tool organizers, ensuring tools are in good condition and easily accessible.

- Adapt to Your Needs: Customize your storage solutions to fit the specific needs of your printing setup and the space you have available.

11. Popular Brands and Where to Buy

When it comes to sourcing high-quality 3D printer supplies, selecting the right brands is crucial for achieving the best results in your 3D printing endeavors. Renowned brands like Hatchbox, eSUN, MatterHackers, and others have established themselves as reliable providers of various 3D printing materials and accessories. Knowing where to purchase these supplies is equally important, with options ranging from online platforms like Amazon to specialty stores and direct purchases from manufacturers. Let’s dive into some of these popular brands and the best places to purchase their products.

Top Brands for Filaments and Where to Buy

- Brands: Hatchbox, eSUN, Prusa Research, MatterHackers, and Ultimaker are some of the leading names in the filament industry, known for their quality and wide range of options.

- Where to Buy:

- Amazon: A vast selection of filaments from various brands, often with quick shipping options.

- Filaments.ca: Ideal for those in Canada, offering a wide range of filaments from different manufacturers.

- MatterHackers: Known for a curated selection of high-quality filaments.

- Manufacturer Websites: For the most direct and comprehensive product range.

Printer Parts and Accessories

- Brands: E3D, Bondtech, Micro Swiss, and BLTouch are highly recommended for reliable printer parts and accessories.

- Where to Buy:

- AliExpress: A great option for budget-conscious buyers looking for a variety of parts.

- Prusa Shop: Ideal for Prusa-specific parts and accessories.

- Official Brand Websites: For guaranteed authenticity and access to the latest products.

Tools and Maintenance Supplies

- Brands: Look for Capricorn for PTFE tubes, PEI sheets from Gizmo Dorks or Prusa, and Noctua for silent cooling fans.

- Where to Buy:

- Major Electronics Retailers: Often stock a variety of tools and maintenance supplies.

- Specialist 3D Printing Shops: Offer specialized tools tailored for 3D printing needs.

- Official Brand Websites: For specific brand purchases and to ensure product authenticity.

Software and Calibration Tools

- Brands: Simplify3D, Cura, and PrusaSlicer are among the top software brands for 3D printing, offering advanced features and user-friendly interfaces.

- Where to Buy:

- Directly from Software Developers’ Websites: This ensures you receive the latest version and direct support.

- Trusted Software Platforms: For secure purchases and potential bundle deals.

12. Money-Saving Tips for 3D Printer Supplies

3D printing can be a rewarding hobby or a valuable asset for businesses, but managing costs is crucial for maximizing its benefits. By adopting smart purchasing strategies and exploring cost-effective alternatives, you can save money on 3d printer supplies without compromising on quality. Let’s dive into some practical tips for saving money on 3D printing supplies, from bulk purchases to DIY maintenance solutions.

Economical Strategies for 3D Printing Supplies

- Bulk Purchases

- Advantages: Buying filaments and other consumables in bulk often leads to discounted rates.

- Storage Considerations: Ensure proper storage for bulk filaments to maintain quality. Use airtight containers with desiccants to protect against moisture.

- Planning: Evaluate your usage patterns to determine the feasibility of bulk purchases without the risk of materials expiring or deteriorating.

- Alternative Filament Brands

- Value Brands: Explore lesser-known filament brands that offer a good balance of quality and price.

- Research: Check user reviews and community feedback to gauge the performance and reliability of these brands.

- Test Purchases: Consider buying a small quantity initially to test the quality before committing to larger purchases.

- DIY Solutions for Maintenance

- Cost-Effective Cleaning: Use isopropyl alcohol for effective cleaning of print beds and parts.

- Lubrication: Regular sewing machine oil can be a budget-friendly alternative for lubricating moving parts.

- Homemade Tools: DIY solutions for tool and part cleaning can be both economical and efficient.

- Discounts and Sales

- Seasonal Sales: Look out for annual sales events like Black Friday or Cyber Monday for significant discounts.

- Newsletter Subscriptions: Many 3D printing suppliers offer exclusive deals to their newsletter subscribers.

- Coupon Hunting: Search for discount codes or coupons online before making a purchase.

- Recycling Failed Prints

- Filament Recycler: Investing in a filament recycler allows you to repurpose failed prints and scrap filament.

- Long-Term Savings: Although recyclers can be an upfront investment, they can lead to substantial savings over time.

- Environmental Benefit: Recycling filament is not only cost-effective but also environmentally friendly.

- Group Buys

- Community Purchases: Participate in group buys organized by 3D printing communities to avail bulk discounts.

- Networking: Join online forums and social media groups dedicated to 3D printing to stay informed about group buying opportunities.

- Consider Compatibility

- Smart Purchasing: Before buying upgrades or add-ons, ensure they are compatible with your printer to avoid wasting money on incompatible items.

- Research: Read product descriptions carefully and consult community forums for compatibility advice.

13. Conclusion

In conclusion, whether you’re looking for high-quality filaments, reliable printer parts, essential maintenance 3d printer supplies, or advanced software, turning to trusted brands is key to enhancing your 3D printing experience. Platforms like Amazon provide a broad range of options, while specialized stores and direct purchases from manufacturer websites offer authenticity and specialized products. Equipping yourself with the right 3d printer supplies from reputable sources ensures that you achieve the best possible outcomes in your 3D printing projects. Remember, the right tools and materials are the backbone of successful 3D printing.

14. FAQs

- Which filament is best for beginners?

PLA is user-friendly and ideal for beginners, also you can check this guide to the best 3d printer for beginners. - How often should I clean my 3D printer?

After every use to ensure longevity. - Can I mix and match brands for supplies?

Yes, but ensure compatibility. - When should I consider upgrading my printer?

If you’re seeking advanced features or better print quality. - Are third-party 3d printer supplies reliable?

Research and reviews are crucial. Some third-party brands offer excellent quality, while others might not.

Hope this guide aids you in your 3D printing journey. Happy printing!

Resources

- https://www.xometry.com/resources/3d-printing/3d-printer-parts/

- https://www.simplify3d.com/

- https://www.prusa3d.com/page/prusaslicer_424/

- https://ultimaker.com/software/ultimaker-cura/

- prusa3d.com

- https://www.matterhackers.com/

- https://store.micro-swiss.com/

- https://www.bondtech.se/

- https://e3d-online.com/

- https://ultimaker.com/