Stratasys 3D Printer: Revolutionizing Prototyping and Production for Every Industry

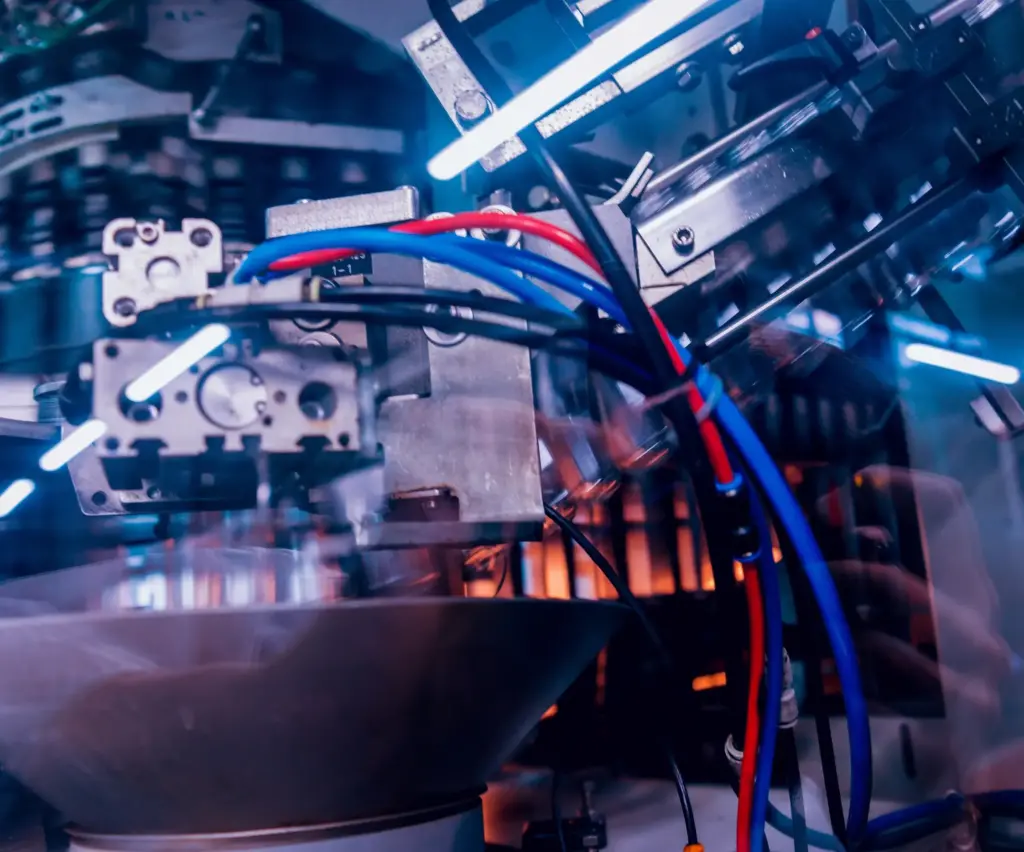

1. Introduction to Stratasys 3D Printer

If you’re diving into the world of 3D printing, one name you’ll definitely come across is Stratasys. They’ve been a pioneer in the 3D printing industry for decades, known for their innovation and top-notch technology. Whether you’re working on rapid prototyping or full-scale manufacturing, Stratasys has a machine that fits your needs. In this guide, I’ll walk you through everything you need to know about Stratasys 3D printer, from the types of printers they offer to their applications across various industries. Trust me, by the end, you’ll understand why Stratasys is often considered the gold standard in 3D printing.

2. Why Stratasys?

Innovation and Leadership

Stratasys has been a leader in the 3D printing industry since its inception. They are constantly pushing the boundaries of what’s possible with additive manufacturing. Their commitment to research and development ensures that their products remain cutting-edge, offering innovative solutions for businesses and individuals alike.

High-Quality Printing Technology

When it comes to print quality, Stratasys is hard to beat. Whether you’re printing functional prototypes, end-use parts, or even medical devices, the precision of their machines is outstanding. Their printers are known for delivering consistent results, which is crucial for industries like aerospace or healthcare, where precision is non-negotiable.

3. Types of Stratasys 3D Printers

One of the things I love about Stratasys is their range of 3D printing technologies. Each technology serves different purposes and caters to specific needs. Let’s break down the most popular types of Stratasys 3D printers:

FDM (Fused Deposition Modeling) Printers

This technology is one of the most common 3D printing technologies, and Stratasys happens to be the inventor of it! FDM printers work by heating thermoplastic filament and depositing it layer by layer to build up a part.

- How FDM Works: The filament is heated to its melting point and extruded through a nozzle onto a build platform. Once the material cools, it solidifies into the desired shape.

Popular Stratasys FDM Printers

Stratasys has a wide range of FDM printers, but the F123 Series is by far one of the most popular. Let’s take a quick look at what each of these models offers:

Stratasys F123 Series

- F170, F270, F370 Features: These models offer a range of build sizes and material capabilities, making them perfect for everything from prototypes to end-use parts. The F370, for example, allows you to print in up to four materials, including high-performance thermoplastics like ABS and ASA.

- Applications of the F123 Series: Whether you’re in product design, manufacturing, or engineering, the F123 Series has something to offer. These printers are known for their ease of use, versatility, and reliable performance.

PolyJet Printers

If you’re looking for something that can handle detailed, multi-material, and multi-color prints, then PolyJet is the way to go.

- How PolyJet Works: This technology works by jetting liquid photopolymer onto the build tray, which is then cured by UV light. The result is a highly accurate and smooth print with incredibly fine details.

Stratasys J-Series Printers

Stratasys J55

The Stratasys J55 is a great option for design studios, offering full-color 3D printing with Pantone validation. It’s perfect for creating prototypes that look just like the final product.

Stratasys J850

On the other hand, the Stratasys J850 is built for more complex and larger-scale projects, making it ideal for industries like automotive, consumer goods, and healthcare.

4. Materials Used in Stratasys 3D Printers

One of the most impressive aspects of the Stratasys 3D printer lineup is the wide range of compatible materials. Whether you’re looking to create simple prototypes or complex, industrial-grade parts, Stratasys printers offer material flexibility that meets almost any need. Understanding the materials used in Stratasys printers helps you choose the right option for your projects, ensuring you get the most out of your 3D printing investment.

Thermoplastics for FDM

Fused Deposition Modeling (FDM) technology is known for its ability to print with durable thermoplastics. Stratasys FDM printers allow you to create parts that are not only strong but also resistant to environmental factors like heat, UV light, and chemicals. Some common thermoplastics used with FDM printers include:

- ABS (Acrylonitrile Butadiene Styrene): ABS is a widely used plastic known for its toughness and durability. It’s a great choice for functional prototypes, tooling, and even end-use parts. ABS parts printed on a Stratasys 3D printer are resistant to impact and can withstand rough handling, making it ideal for automotive and industrial applications.

- ASA (Acrylic Styrene Acrylonitrile): ASA is similar to ABS but offers better UV resistance, making it perfect for outdoor applications. If you’re designing outdoor equipment or parts that need to endure sun exposure, ASA is the way to go. ASA also prints with a superior surface finish, giving your parts a more polished look.

- Nylon: Known for its flexibility and strength, Nylon is a fantastic choice for parts that require both durability and impact resistance. Parts printed with Nylon are perfect for creating hinges, gears, and other functional prototypes.

- ULTEM: This is one of the most high-performance thermoplastics available for FDM technology. ULTEM is heat-resistant, chemically resistant, and incredibly strong. This material is commonly used in aerospace and medical industries, where durability and safety are top priorities. If you’re looking to create parts that can withstand extreme conditions, ULTEM is a material to consider.

Resins for PolyJet

PolyJet technology is another popular choice among Stratasys 3D printer users, especially for those who need highly detailed parts with a smooth surface finish. PolyJet printers use photopolymer resins that are jetted onto a build platform and cured by UV light. These resins offer a lot of flexibility in terms of texture, color, and material properties.

- Full-color resins: One of the standout features of PolyJet printers is their ability to print in full color. Stratasys PolyJet printers can create incredibly realistic prototypes with true-to-life colors, which is a game-changer for industries like consumer goods and product design.

- Flexible resins: If you need a material that mimics the properties of rubber or silicone, PolyJet offers flexible resins. These materials are perfect for creating parts like seals, gaskets, or any other application that requires flexibility.

- Transparent resins: Need to create clear or semi-transparent parts? Stratasys PolyJet printers can print with transparent resins, allowing you to create lenses, medical devices, or other products that require visibility.

High-Performance Materials (ULTEM, PEEK)

When you move into industrial applications, Stratasys 3D printers can handle high-performance materials like ULTEM and PEEK. These materials are known for their exceptional strength, chemical resistance, and thermal stability, making them ideal for parts that need to withstand extreme environments.

- ULTEM: As mentioned earlier, ULTEM is a highly versatile material that’s used in aerospace, medical, and automotive industries. Its ability to resist heat and chemicals makes it perfect for applications where safety and durability are critical.

- PEEK (Polyether Ether Ketone): PEEK is another industrial-grade material that offers exceptional mechanical properties. It’s often used in aerospace and automotive industries for parts that need to endure high stress and temperatures. If you’re working on a project that requires long-term performance under extreme conditions, PEEK is a material worth considering.

5. Industries Using Stratasys 3D Printers

Stratasys 3D printers have a broad range of applications across various industries. From aerospace to healthcare, these printers are revolutionizing the way companies approach manufacturing, prototyping, and even medical treatments. Let’s dive into how different industries are benefiting from the Stratasys 3D printer technology.

Aerospace

The aerospace industry has been one of the earliest adopters of 3D printing technology, and Stratasys continues to be a leader in this sector. One of the primary reasons for using Stratasys 3D printers in aerospace is the ability to create lightweight parts that still maintain structural integrity.

- Lightweight prototypes: Reducing the weight of aircraft components can result in significant fuel savings, which is why aerospace companies use Stratasys FDM printers to create lightweight yet durable prototypes.

- End-use parts: Stratasys printers are also used to create end-use parts for aircraft. These parts can range from brackets to cabin components, all while meeting the stringent safety and performance standards required in aviation.

Automotive

The automotive industry is constantly seeking ways to improve efficiency, reduce production costs, and create more customized products. Stratasys 3D printers are making all of these goals more achievable.

- Custom tools and jigs: Automotive companies use Stratasys printers to create custom tools and jigs, which can significantly speed up the production process. Instead of waiting weeks for a custom tool to be manufactured, it can be 3D printed in-house in just a matter of hours or days.

- Prototypes for testing: Car manufacturers use Stratasys printers to create functional prototypes that can be tested for fit, function, and performance. This not only speeds up the design process but also helps reduce costs by identifying potential issues before moving into full-scale production.

- End-use parts: Some automotive companies are even using Stratasys FDM printers to create end-use parts. For example, small plastic components that might have previously been injection molded can now be 3D printed, reducing lead times and allowing for more customization.

Healthcare

Perhaps one of the most exciting applications of Stratasys 3D printers is in the healthcare field. Medical professionals are using these printers to create everything from prosthetics to surgical planning models.

- Prosthetics: Custom prosthetics can be 3D printed to perfectly match the unique needs of each patient. This not only speeds up the production process but also makes it more affordable for patients to receive high-quality, custom-made prosthetics.

- Anatomical models: Surgeons are using Stratasys PolyJet printers to create detailed anatomical models that replicate a patient’s specific anatomy. These models allow surgeons to plan and practice complex procedures before entering the operating room, which can significantly improve patient outcomes.

- Medical devices: Stratasys printers are also used to create custom medical devices, such as braces or even implants. The ability to customize each device to the patient’s specific needs is a game-changer in the medical field.

Education and Prototyping

Stratasys 3D printers are also widely used in education and research facilities. By providing students and researchers with hands-on experience in additive manufacturing, Stratasys is helping to shape the next generation of engineers, designers, and innovators.

- Prototyping: Educational institutions use Stratasys FDM and PolyJet printers to teach students how to design, prototype, and manufacture parts. The ability to quickly iterate on designs and see them come to life helps students develop a deeper understanding of engineering and product development.

- Research and innovation: Researchers are using Stratasys 3D printers to explore new materials, manufacturing techniques, and even medical treatments. The versatility and precision of Stratasys printers make them ideal for pushing the boundaries of what’s possible in science and engineering.

6. Benefits of Using Stratasys 3D Printers

If you’re still wondering why Stratasys stands out in the 3D printing industry, here are some of the key benefits:

- Precision and Accuracy: Whether it’s FDM or PolyJet, Stratasys printers deliver unmatched precision, making them ideal for industries that require tight tolerances.

- Versatile Material Compatibility: From thermoplastics to liquid resins, Stratasys printers can handle a wide range of materials, giving you the flexibility to print exactly what you need.

- Prototyping and Production Capabilities: These machines aren’t just for prototyping anymore. With the right Stratasys printer, you can print functional, end-use parts for production.

7. How to Choose the Right Stratasys 3D Printer for You

Now that you’re familiar with the different types of Stratasys printers, you might be wondering how to choose the right one for your needs. Here’s a quick guide:

- Consider Your Application: Are you printing for prototypes, end-use parts, or detailed models? This will help you choose between FDM and PolyJet.

- Understand the Printing Technology: If you need something simple and robust, go for FDM. For more intricate designs with multiple materials, PolyJet is your best bet.

- Material Requirements and Budget: Make sure to consider the types of materials you need and your budget when selecting a printer.

8. Conclusion

Choosing a 3D printer can be a daunting task, but Stratasys simplifies the decision-making process with its reliable, high-performance machines. Whether you’re a beginner looking to create prototypes or an industry expert aiming to produce end-use parts, Stratasys offers the right printer for you. Their innovation, material versatility, and industry-leading technology make them a top choice in the 3D printing world. Ready to get started with Stratasys? Dive in and see for yourself why this brand has set the standard for 3D printing.

9. FAQs

- What materials can I use with Stratasys 3D printers?

Stratasys printers can handle various materials such as thermoplastics (ABS, ASA, Nylon), high-performance materials (ULTEM, PEEK), and photopolymers for PolyJet printing. - Which industries benefit the most from Stratasys printers?

Industries like aerospace, automotive, healthcare, and education heavily rely on Stratasys for creating precise and functional parts. - What is the difference between FDM and PolyJet technology?

FDM builds parts layer by layer using thermoplastics, while PolyJet jets liquid resins to create highly detailed, multi-material, and multi-color prints. - How do I maintain my Stratasys printer?

Regular calibration, keeping the printer clean, and ensuring the materials are loaded correctly are key to maintaining your Stratasys printer. - Are Stratasys printers good for beginners?

Absolutely! Stratasys offers user-friendly options like the F123 series, which are great for beginners who are new to 3D printing.

Resources