Plasma Cutter 3D Print: Craft Your Own Iconic Project

1. Introduction

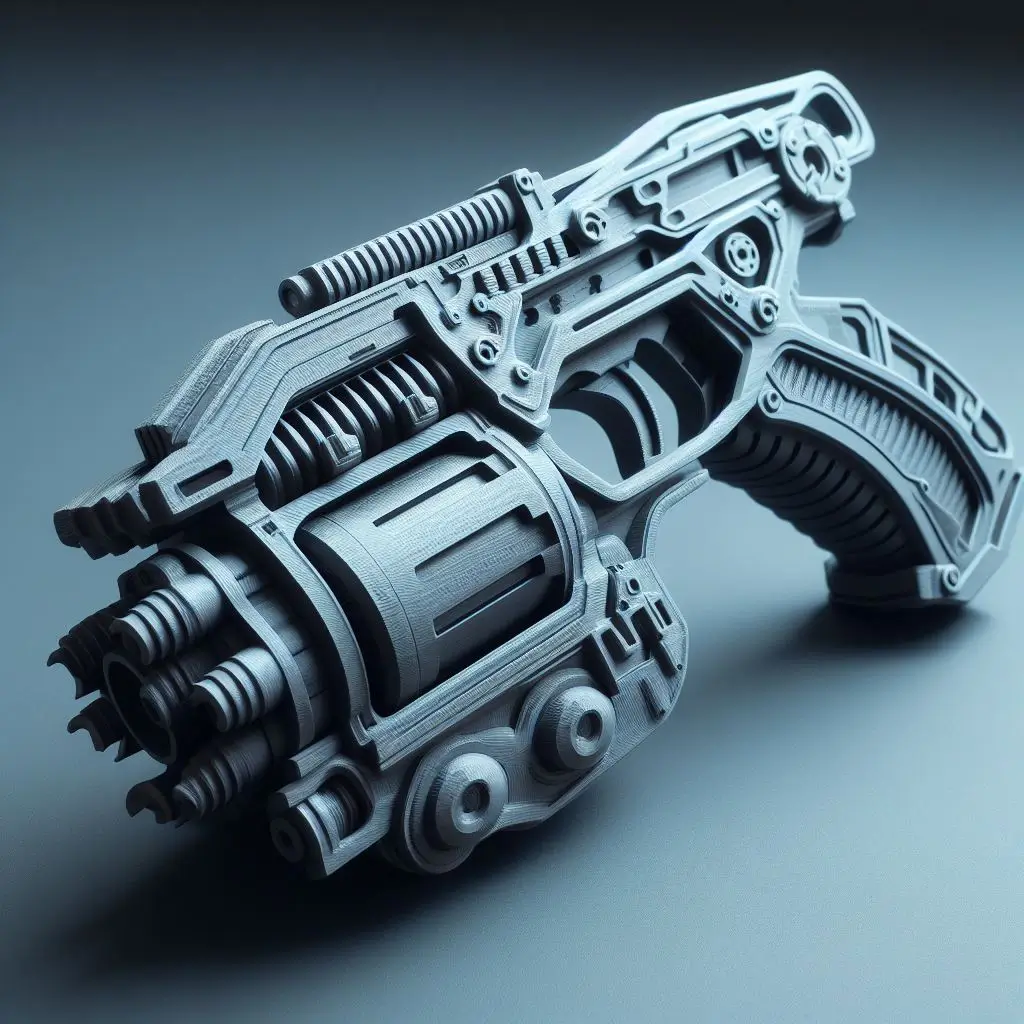

Hey there, fellow makers and prop enthusiasts! Ever marveled at the sleek, dangerous look of a plasma cutter, especially those iconic ones from your favorite video games or movies? Imagine holding a replica in your hands, not just any replica, but one you made yourself. This guide is all about turning that fantasy into reality through the magic of 3D printing. We’re diving deep into how to 3D print your very own plasma cutter model, from start to finish. Whether you’re looking to enhance your cosplay, add to your collection of movie memorabilia, or simply take on a thrilling DIY project, you’re in the right place.

2. Understanding Plasma Cutters

What Is a Plasma Cutter?

Before we jump into the 3D printing process, let’s get to know our star a little better. A plasma cutter, in the real world, is a tool used to cut through various conductive materials, such as steel and aluminum, using a jet of hot plasma. Pretty cool, right? But in the realm of sci-fi and video games, these tools often take on a more futuristic and sometimes more versatile role, capable of cutting through just about anything the hero (or villain) encounters.

The Role of Plasma Cutters in Popular Media

Plasma cutters have carved out a niche in popular media, symbolizing cutting-edge technology and often playing key roles in storylines. Whether it’s the precision tool for engineering feats or a weapon against menacing extraterrestrial threats, its depiction has always been fascinating and, frankly, cool. This has made it a popular choice for cosplayers and prop makers looking to bring a piece of their favorite worlds into reality.

3. Preparing for Your 3D Print

When embarking on a “plasma cutter 3D print” project, preparation is key. This stage involves making informed decisions on the model to print, selecting the appropriate materials, and ensuring you have all the necessary tools and equipment at your disposal. Let’s delve into these crucial steps to ensure your project not only starts off on the right foot but also reaches a successful and satisfying completion.

Choosing the Right 3D Model

Sources for Plasma Cutter Models: In the world of 3D printing, the model you choose to print is the foundation of your project. Websites like Thingiverse, MyMiniFactory, and CGTrader are excellent resources, offering a wide range of 3D models suitable for various projects, including plasma cutter replicas. These platforms provide models ranging from exact replicas seen in popular games and movies to unique and original designs. Here are a few tips for selecting the right model:

- Research: Spend time browsing through different models to find the one that best matches your vision.

- Compatibility: Ensure the model is compatible with your 3D printer’s specifications and capabilities.

- Legality: Always respect copyright laws. Opt for models that are legally available for free or for which you’ve obtained permission to use.

Selecting Your 3D Printing Material

The material you choose for your 3D print plays a significant role in determining the final product’s appearance, feel, and durability. Here’s a brief overview of popular materials:

- PLA (Polylactic Acid): Known for its ease of use and being environmentally friendly, PLA is ideal for beginners and those looking for a material with minimal warping issues.

- ABS (Acrylonitrile Butadiene Styrene): Offers enhanced strength and flexibility but requires more advanced handling, such as a heated print bed and good ventilation to manage fumes.

When selecting a material for your “plasma cutter 3D print,” consider the following factors:

- Detail and Precision: If your model features intricate details, a material like PLA might be more suitable.

- Durability: For a prop that will be handled frequently, ABS could offer the necessary resilience.

- Finish and Post-Processing: Some materials are easier to sand, paint, and finish than others. Consider your post-printing plans when choosing.

Tools and Equipment Needed

Beyond the 3D printer itself, a successful print requires a few additional tools and equipment:

- Sandpaper and Filing Kit: Essential for smoothing out imperfections and preparing your print for painting and finishing.

- Paints and Brushes: Quality paints and a range of brush sizes will allow you to bring your plasma cutter to life with detailed painting.

- Super Glue or Plastic Welder: For assembling multiple pieces or adding components to your model.

- LEDs or Electronic Components (Optional): Adding lighting effects can elevate your plasma cutter from a simple replica to a dynamic piece of art.

Quick Checklist:

- Selected 3D model

- 3D printing material

- Sandpaper/filing kit

- Paints and brushes

- Adhesive for assembly

- LEDs/electronics (optional)

By carefully preparing for your “plasma cutter 3D print” project and considering each of these elements, you can ensure a smoother process and a final product that’s as close to your vision as possible.

4. The 3D Printing Process

Embarking on a “plasma cutter 3D print” project is an exciting venture that merges creativity with technical skill. The 3D printing process is at the heart of bringing your plasma cutter from digital design to physical reality. Here, we’ll delve deeper into the steps and strategies to ensure a successful print, alongside troubleshooting common issues that might arise. This comprehensive guide aims to empower you with knowledge and confidence as you navigate the printing process.

Step-by-Step Guide to Printing

Prepare Your Printer: First things first, a well-calibrated 3D printer is paramount for a successful print. Here’s how to get started:

- Ensure your print bed is perfectly level. An uneven bed can lead to adhesion problems and uneven layers.

- Clean the print bed to improve first layer adhesion. A clean surface can significantly reduce the chances of warping.

Slice Your Model: Slicing your 3D model is like preparing a blueprint for your printer to follow. Here’s what to focus on:

- Use slicing software to convert your 3D model into a language your printer understands.

- Adjust layer height for a balance between print quality and time. Lower layer heights yield finer details but increase print duration.

- Infill density affects the model’s strength and weight. A higher infill density makes your plasma cutter more durable but uses more material.

Start Printing: With preparations complete, it’s time to bring your model to life.

- Begin your print and watch the first few layers closely. Good adhesion at this stage is crucial for a successful print.

- Adjustments made early can save time and materials in the long run.

Monitor the Print: Vigilance during printing can prevent many common issues.

- Check in periodically to ensure the print is progressing smoothly.

- Look out for signs of trouble, such as filament tangles or shifting layers, and pause the print if necessary to make adjustments.

Troubleshooting Common Issues

Warping: This is when the corners of your print lift off the print bed, often due to poor adhesion or temperature variations.

- Solutions include using a heated bed, applying an adhesive like glue stick or hairspray, and ensuring consistent ambient temperatures.

Nozzle Clogging: Filament can sometimes clog the nozzle, leading to under-extrusion or complete print failure.

- Regular maintenance, such as cleaning the nozzle and using high-quality filament, can prevent clogs.

- If a clog occurs, carefully remove the filament and clean the nozzle using appropriate tools.

Layer Shifting: This happens when the print layers do not align correctly, usually due to loose belts or vibrations.

- Ensure all moving parts, especially belts and pulleys, are tight and well-lubricated.

- Reduce print speed to minimize vibrations that can lead to shifting.

5. Post-Printing Processes

Completing a “plasma cutter 3D print” project doesn’t end when your printer stops; that’s when the next crucial phase begins to bring your creation to its full potential. The post-printing process involves several steps: cleaning and smoothing, painting and detailing, and assembly, possibly including electronics for enhanced realism. Each of these steps is vital to transforming your print from a simple plastic model into a convincing replica of a plasma cutter.

Cleaning and Smoothing Your Print

After the excitement of seeing your print complete, it’s time to get down to the nitty-gritty of post-processing. This stage is crucial for achieving a professional and high-quality finish.

- Removing Support Structures: Carefully remove any supports with pliers or your hands, being mindful not to damage the print itself.

- Sanding: Start with coarse sandpaper to remove larger imperfections, then gradually move to finer grits for a smooth finish. Wet sanding can be especially effective for achieving a glossy surface.

- Filing: For hard-to-reach areas or intricate details, needle files can be invaluable. They allow you to smooth surfaces without compromising the print’s detail.

Painting and Detailing

The painting phase is where your plasma cutter truly starts to come to life, allowing you to add your personal touch and make it as accurate or imaginative as you wish.

- Priming: A good primer not only helps the paint adhere better but also fills in minor flaws. Apply a thin, even coat and allow it to dry completely.

- Painting: Acrylic paints are a popular choice for 3D printed objects due to their ease of use and compatibility with materials like PLA and ABS.

- Base Coat: Start with a base coat to establish the primary color of your plasma cutter. This layer serves as a foundation for additional colors and details.

- Layering Colors: Add depth and dimension by applying multiple layers of paint. Allow each layer to dry thoroughly before applying the next.

- Detailing: Utilize a fine brush for intricate details. This can include adding weathering effects, highlights, and shadows to create a more realistic appearance.

Assembly and Electronics (If Applicable)

For models that consist of multiple pieces or require additional components for functionality, assembly is the final step in bringing your plasma cutter to life.

- Gluing: Use super glue or a plastic welder to securely join pieces. Ensure a clean, firm bond by applying pressure until the adhesive sets.

- Electronics: Adding LED lights can elevate your plasma cutter from a static model to a dynamic prop. A basic circuit involving a battery, switch, and LED can simulate the plasma cutter’s energy source, adding a captivating glow.

- Planning: Before assembly, plan where your electronics will fit within the model. Consider battery access for replacements.

- Installation: Securely place the LED in the desired location, and ensure wires are neatly tucked away and insulated to prevent short circuits.

6. Displaying Your Plasma Cutter

Creating a “plasma cutter 3D print” is only part of the journey. Once you’ve crafted your masterpiece, displaying it or integrating it into your activities can be equally rewarding. Whether you’re showcasing it as a piece of art, using it as a prop for cosplay, or making it a functional part of your home decor, there are several creative ways to enjoy your finished project. However, it’s also important to consider safety precautions due to its realistic appearance.

Ideas for Display and Use

Cosplay: For cosplay enthusiasts, a 3D-printed plasma cutter can elevate your costume, making you stand out at conventions, parties, or photo shoots. Here’s how to incorporate it into your ensemble:

- Accuracy: Match your plasma cutter to your character’s outfit for a cohesive look.

- Functionality: Modify your plasma cutter to be wearable or easily carried to enhance your cosplay experience.

Display Shelf: Turning your plasma cutter into a showpiece within your home or office is a great way to display your craftsmanship.

- Custom Stand: Design a stand that complements your plasma cutter, highlighting its features.

- Lighting: Use spotlights or LED strips to accentuate the plasma cutter, drawing attention to the intricate details of your work.

Functional Art: Beyond being a display piece, your plasma cutter can serve a functional purpose in your home.

- Conversational Piece: Position it in a common area to spark conversations with guests.

- Thematic Decoration: Incorporate it into themed decor, especially if you have a dedicated gaming or movie room.

Safety Precautions

Given the realistic appearance of your “plasma cutter 3D print,” it’s crucial to handle and display it responsibly to avoid misunderstandings or concerns:

- Public Spaces: Be cautious when bringing your plasma cutter to public events or spaces. Ensure it’s clear that it’s a replica and not a real weapon.

- Legal Considerations: Familiarize yourself with local laws and regulations regarding replica weapons. Some areas may have restrictions or require specific markings to distinguish them as non-functional.

- Storage: When not in use, store your plasma cutter in a safe location, away from children or anyone who might mistake it for a real weapon.

7. Conclusion

Congratulations! You’ve just navigated the exciting journey of 3D printing your own plasma cutter. This project not only tests your making skills but also lets you hold a piece of your favorite universe in your hands. Whether for cosplay, display, or simply the joy of creating, the experience of bringing a plasma cutter from screen to reality is uniquely satisfying. Share your creation with the world, inspire others, and never stop making.

8. FAQs

- What’s the best material for 3D printing a plasma cutter?

PLA is great for beginners due to its ease of use, while ABS offers more durability for experienced users. - How long does it take to 3D print a plasma cutter?

It depends on the size and complexity of your model, as well as your printer settings. Expect anywhere from several hours to a few days. - Can I sell my 3D-printed plasma cutter?

Be mindful of copyright laws regarding the design. If the model is your original creation or you have permission, you may be able to sell it. - Do I need a high-end 3D printer to make a plasma cutter?

Not necessarily. Even entry-level 3D printers can produce great results with proper setup and patience. - How can I make my plasma cutter glow like in the games/movies?

Incorporating LED lights into your design can mimic the glow effect, adding realism to your replica.

Resources